Construction method of railway single-track tunnel with central deep-buried ditch in alpine region

A technology for tunnel construction and alpine regions. It is applied in tunnels, drainage, earthwork drilling and mining, etc. It can solve the problems that the construction method cannot meet the progress requirements and quality requirements, and achieve the effects of shortening the construction period, improving construction quality, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

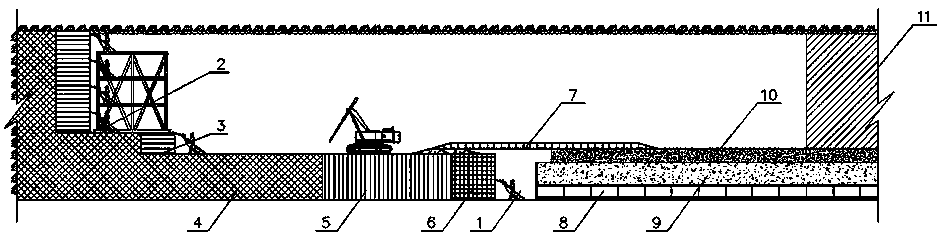

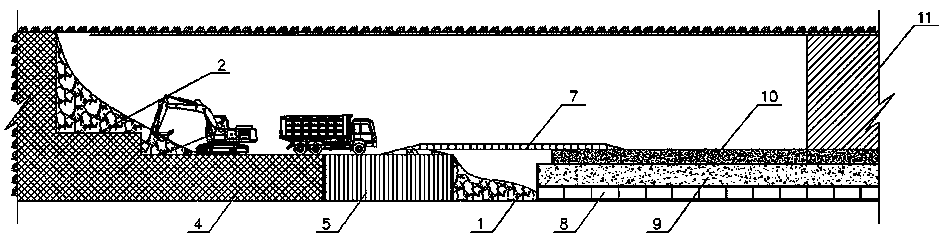

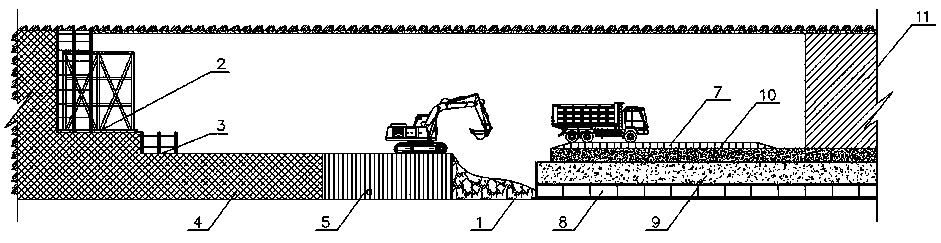

[0024] In the following, the excavation depth of the deep buried ditch in the center is 3.27 meters (greater than the local maximum freezing depth of 1.1m), and the IV level surrounding rock single-line tunnel constructed by the upper and lower steps method is taken as an example to illustrate the central depth of the alpine zone described in the present invention. The railway single-track tunnel construction method of the buried ditch specifically includes the following steps:

[0025] The first step is to calculate the width of the upper opening, the length of the lower bottom, the depth of the ditch, the slope of the side slope, etc. The specific location of the deep-buried ditch 1 will be marked with red eye-catching paint after setting out on site, in preparation for the next step of drilling pre-splitting holes.

[0026] The second step, such as figure 1 As shown, the drilling and blasting excavation of the upper step 2 and lower step 3 of the tunnel and the drilling an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com