Self-locking mechanism under resistance and hand rocking device

A self-locking and blocking technology, applied in the field of clothes dryers, can solve the problems of wire ropes being easily broken, affecting service life, and wire rope knotting, etc., to avoid repeated folding of wire ropes, prolong service life, and prevent reverse winding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

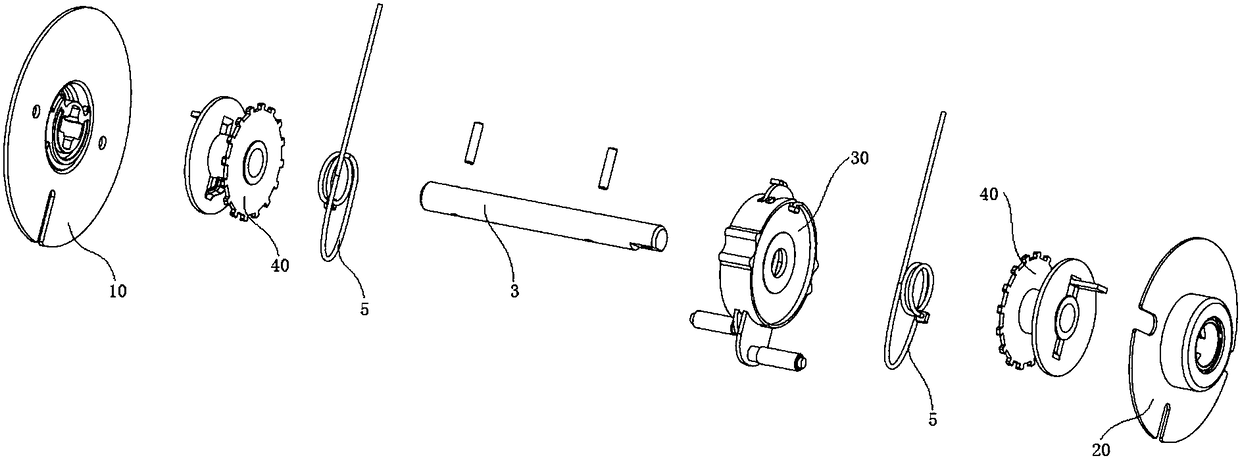

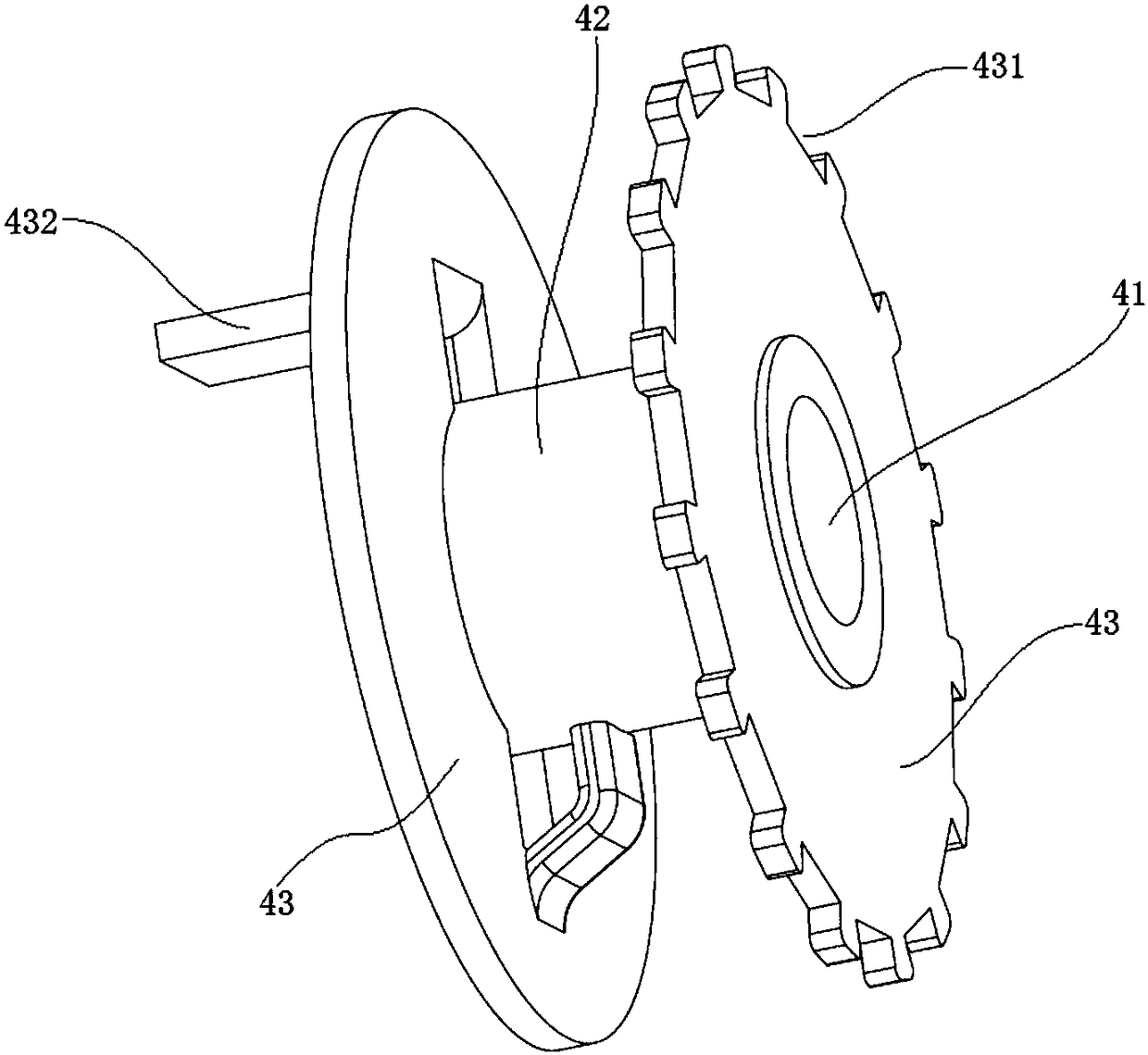

[0034] see Figure 1-5 , the resistance self-locking mechanism shown in the preferred embodiment of the present invention is set on the transmission shaft 3 of the hand crank, including the rear self-locking spring cup assembly 10, the front self-locking spring cup assembly 20, and the resistance self-locking assembly 30 And two spools 40 installed on both sides of the self-locking assembly 30 when blocked.

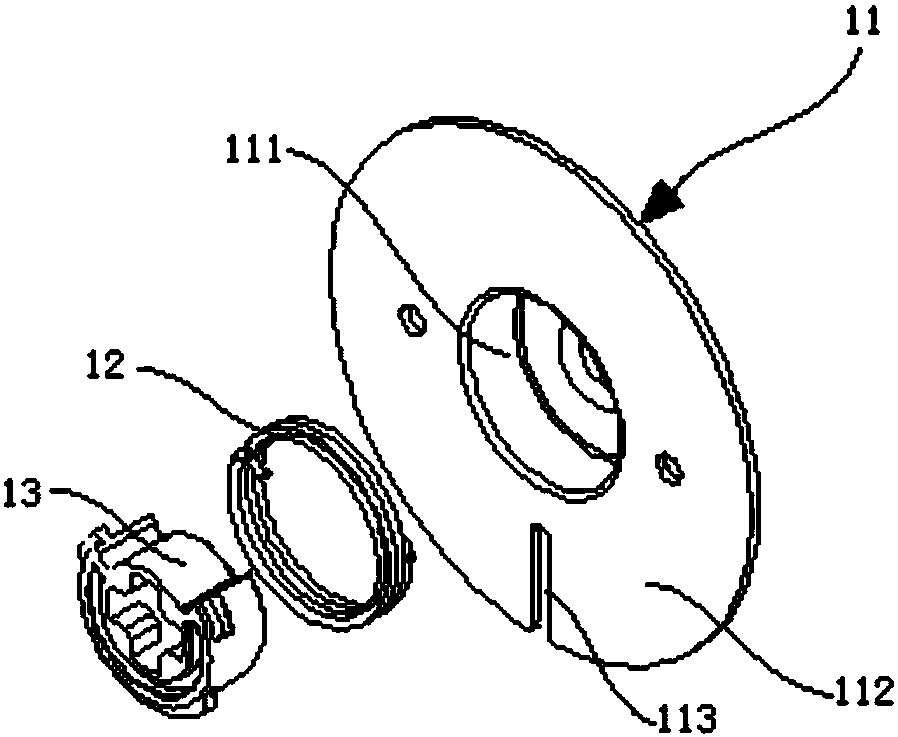

[0035] The rear self-locking spring cup assembly 10 and the front self-locking spring cup assembly 20 are mounted on both ends of the blocked self-locking mechanism in one-to-one correspondence. Any self-locking spring cup assembly (rear self-locking spring cup assembly 10 or front self-locking spring cup assembly 20) cooperates with adjacent I-shaped wheels 40 to realize self-locking. The structure of the rear self-locking spring cup assembly 10 is basically the same as that of the front self-locking spring cup assembly 20, the only difference being that the front self-...

Embodiment 2

[0048] see Figure 6-9 , the present invention also discloses a hand crank 101, which includes a housing 2, a transmission shaft 3, a crank handle 4, and a self-locking mechanism in case of resistance. The locking mechanisms are the same, and will not be described one by one in this embodiment.

[0049] The housing 2 has an accommodating cavity for installing the blocked self-locking mechanism. The blocked self-locking mechanism is installed in the accommodating cavity of the housing 2 . The spring cup 11 and the anti-loosening cover 31 are fixedly installed in the housing 2 .

[0050] One end of the transmission shaft 3 passes through the self-locking spring cup assembly, an I-shaped wheel 40, the self-locking assembly 30 in case of resistance, another I-shaped wheel 40, and the rotor 13 of the rear self-locking spring cup assembly 10 in turn. The other end passes through the housing 2 and is connected to the crank handle 4 . The user rotates the crank handle 4 to drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com