Method for measuring dry coating amount of transfer film coating

A measurement method and a technology for dry coating of coatings, applied in measurement devices, instruments, etc., can solve problems such as low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

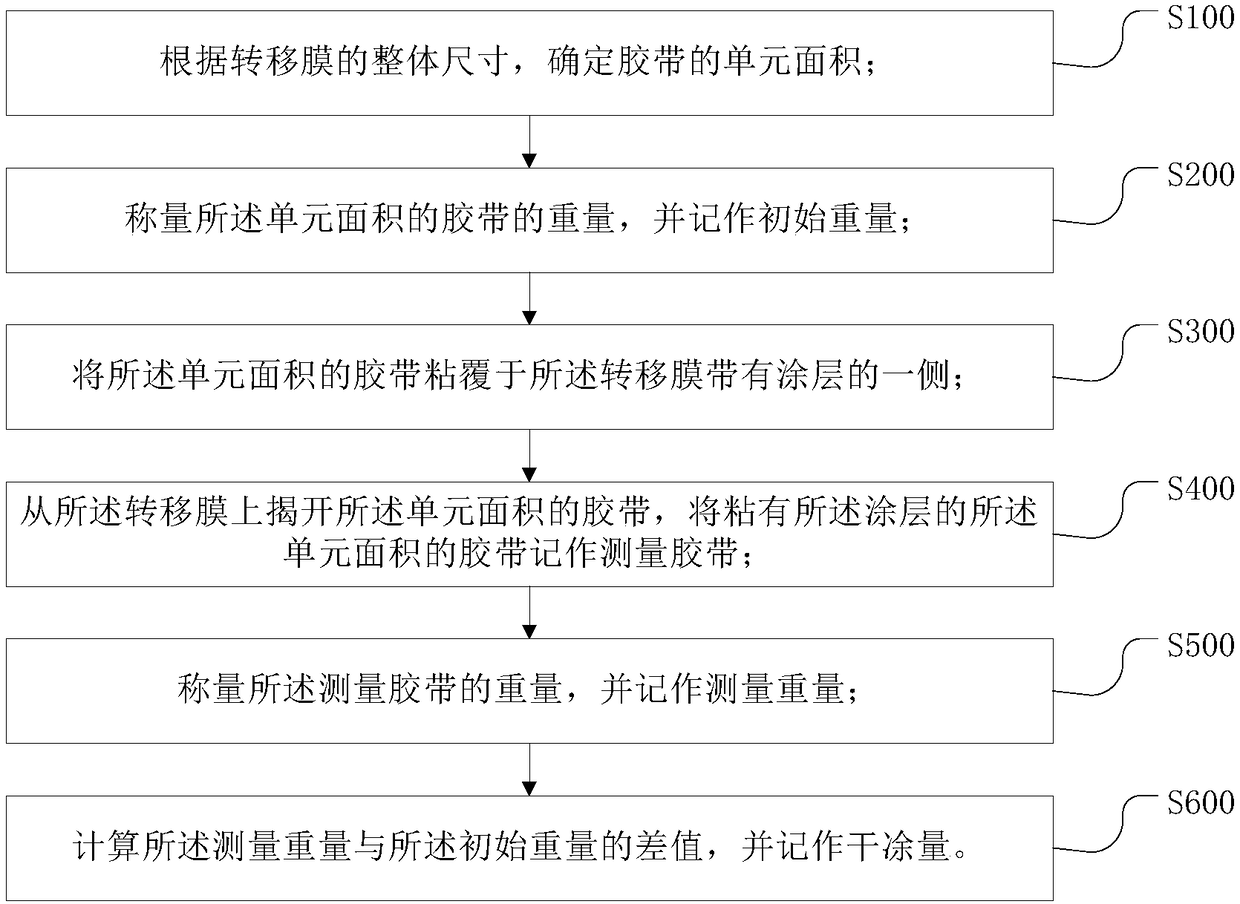

[0034] see figure 1 , a flow chart of a method for measuring dry coating weight of a transfer film coating.

[0035] The present embodiment provides a kind of measuring method of dry coating amount of transfer film coating, comprising:

[0036] S100. Determine the unit area of the adhesive tape according to the overall size of the transfer film;

[0037] S200, weighing the weight of the adhesive tape of the unit area, and recording it as the initial weight;

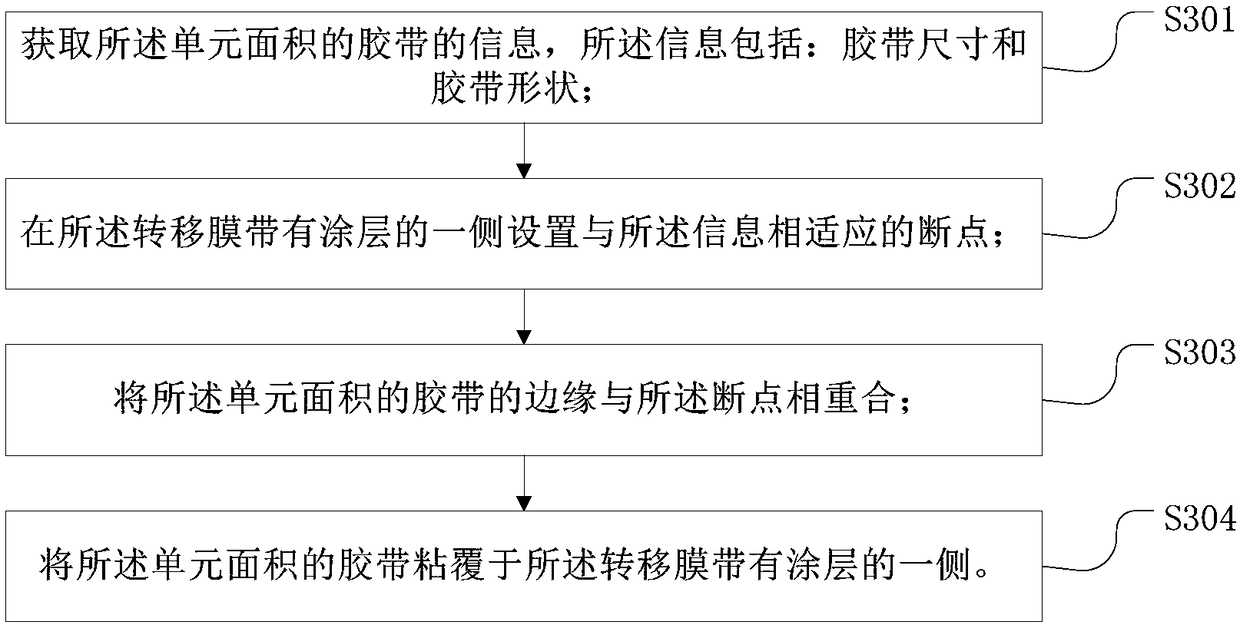

[0038] S300, sticking the adhesive tape of the unit area on the coated side of the transfer film;

[0039] S400, peel off the adhesive tape of the unit area from the transfer film, and record the adhesive tape of the unit area with the coating as the measuring tape;

[0040] S500, weigh the weight of the measuring tape, and record it as the measuring weight;

[0041] S600. Calculate the difference between the measured weight and the initial weight, and record it as the dry coating amount.

[0042] According to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com