A device for measuring ice thickness based on piezoresistive sensor

A technology of piezoresistive sensors and measuring devices, which is applied in the direction of electromagnetic measuring devices, electric/magnetic thickness measurement, etc., can solve the problems that the position of the upper interface of the ice layer cannot be accurately determined, and the thickness of the ice layer cannot be accurately measured, so as to achieve structural Simple, convenient installation and maintenance, accurate thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

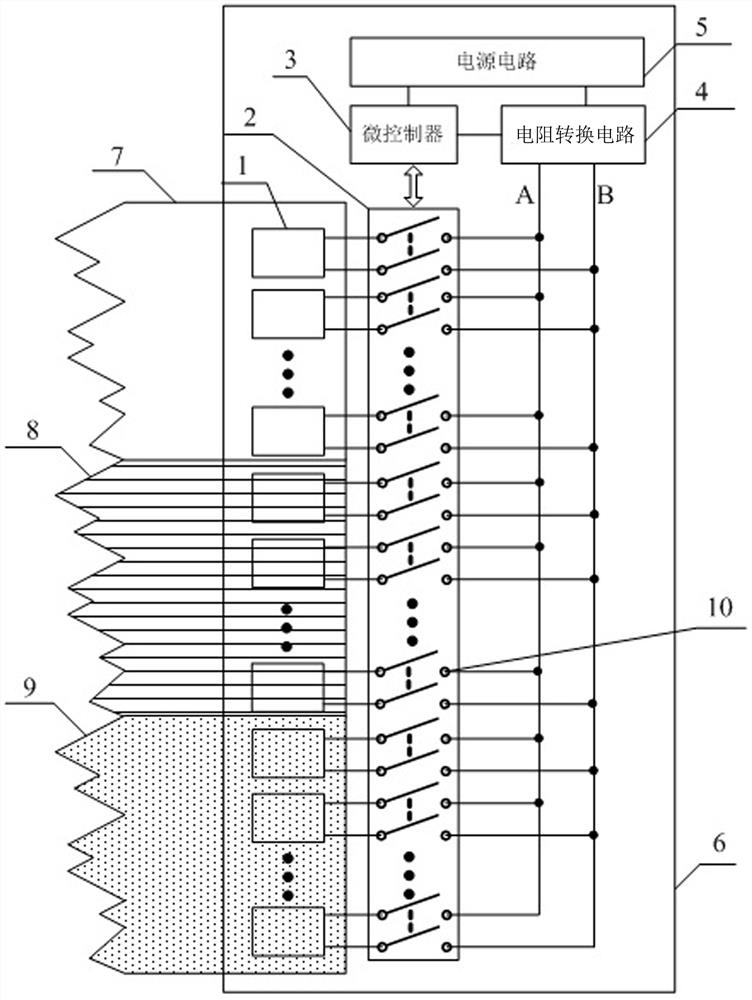

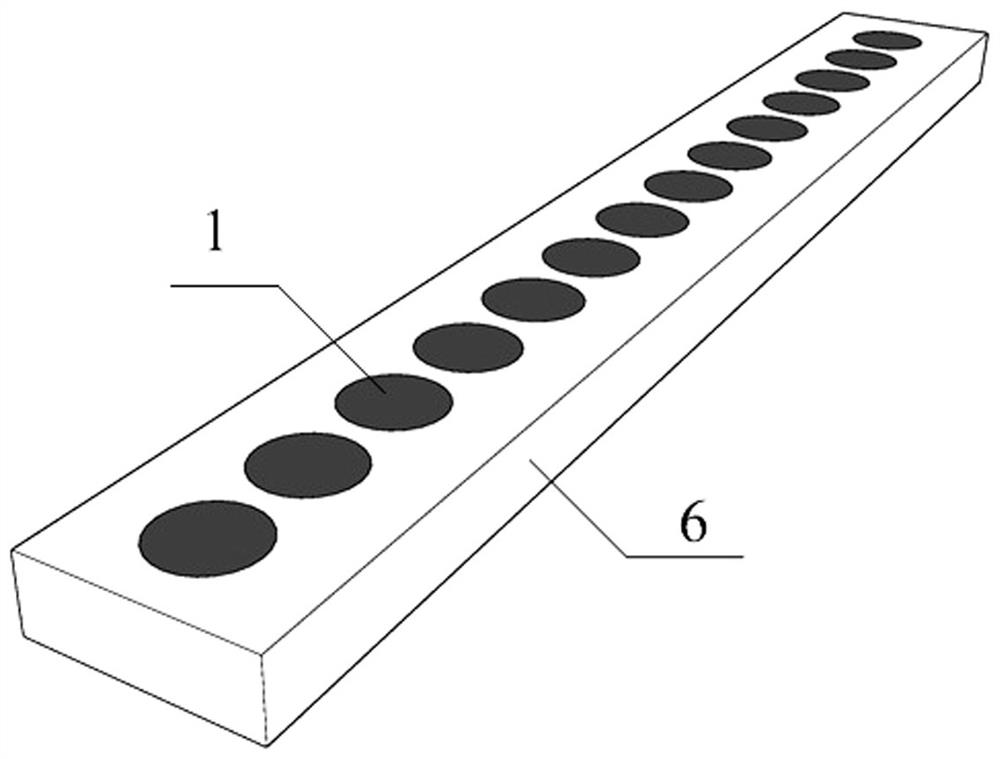

[0016] The present invention includes a piezoresistive sensor 1, a chip selection circuit 2, a microcontroller 3, a resistance conversion circuit 4, a power supply circuit 5 and a housing 6, such as figure 1 shown.

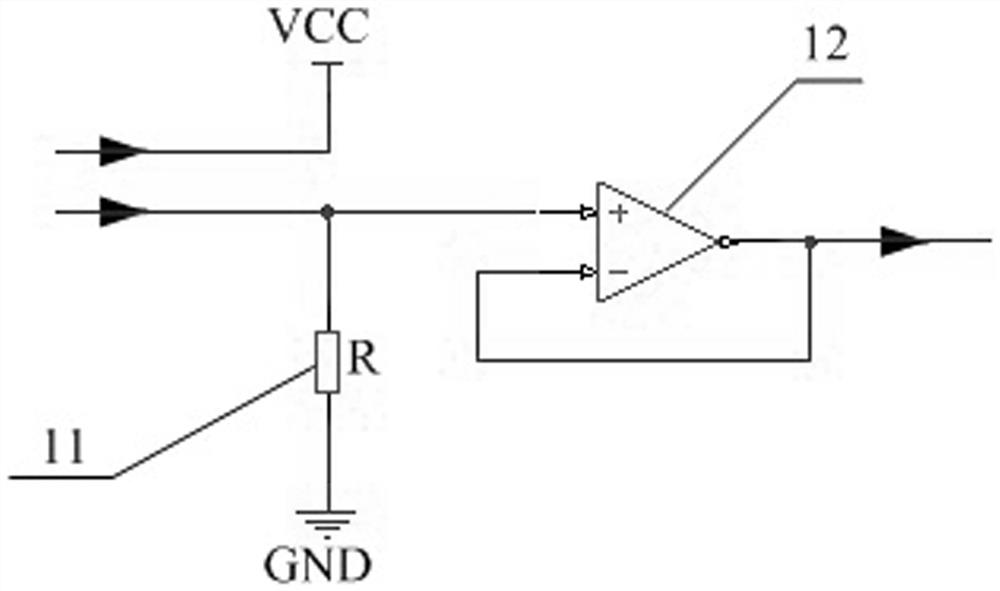

[0017] Several independent piezoresistive sensors 1 are fixed on the outer surface of the casing 6 at equal intervals. Chip selection circuit 2 , microcontroller 3 , resistance conversion circuit 4 and power supply circuit 5 are all located inside the shell 6 . The chip selection circuit 2 includes a plurality of chip selection switches 10, and the chip selection switches 10 are connected through a data bus. Each piezoresistive sensor 1 is provided with two pins, and the number of chip selection switches 10 is consistent with the total number of pins of all piezoresistive sensors 1 . Each pin of the piezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com