Plastic guardrail

A kind of guardrail and plastic technology, applied in the direction of roads, road safety devices, roads, etc., can solve the problems of easy damage in sequence, additional damage, small effect, etc., to achieve the effect of mitigating the impact and reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

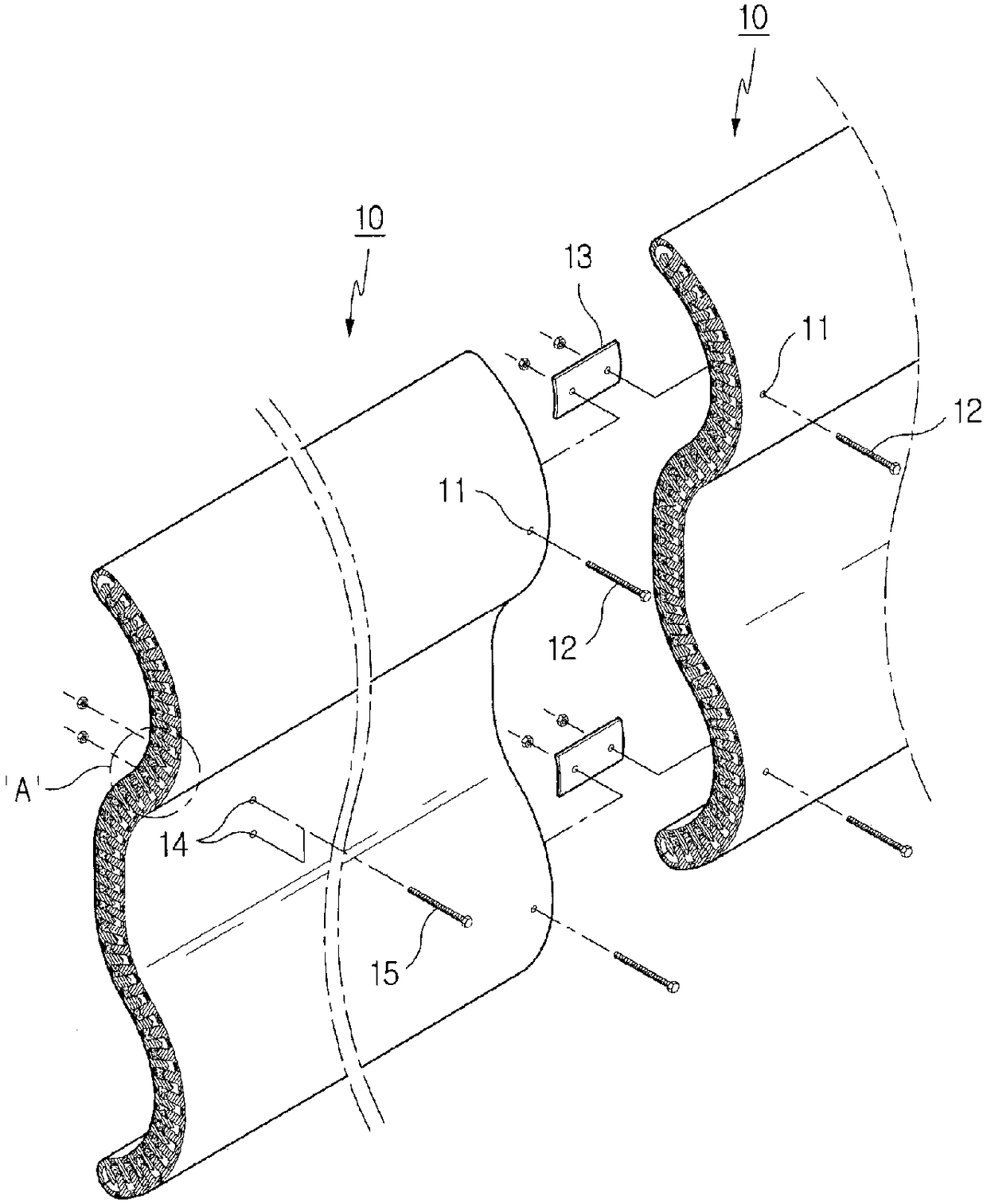

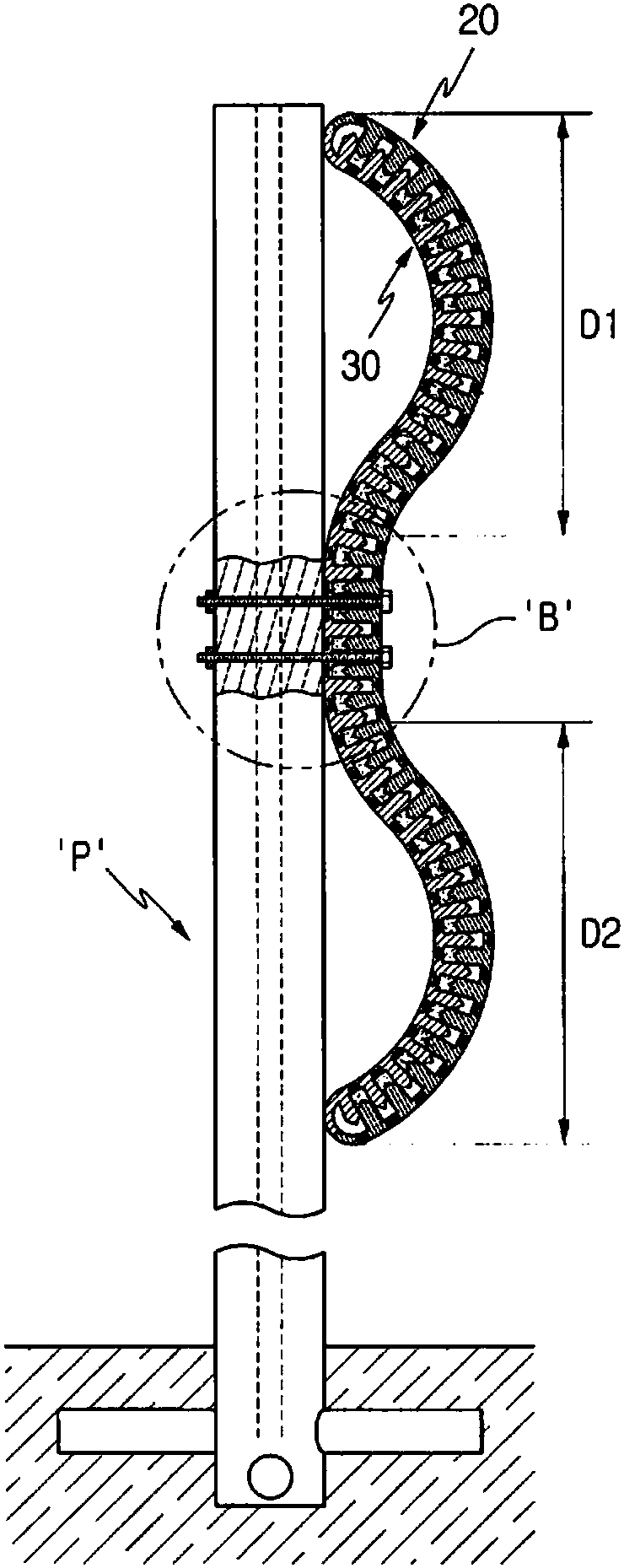

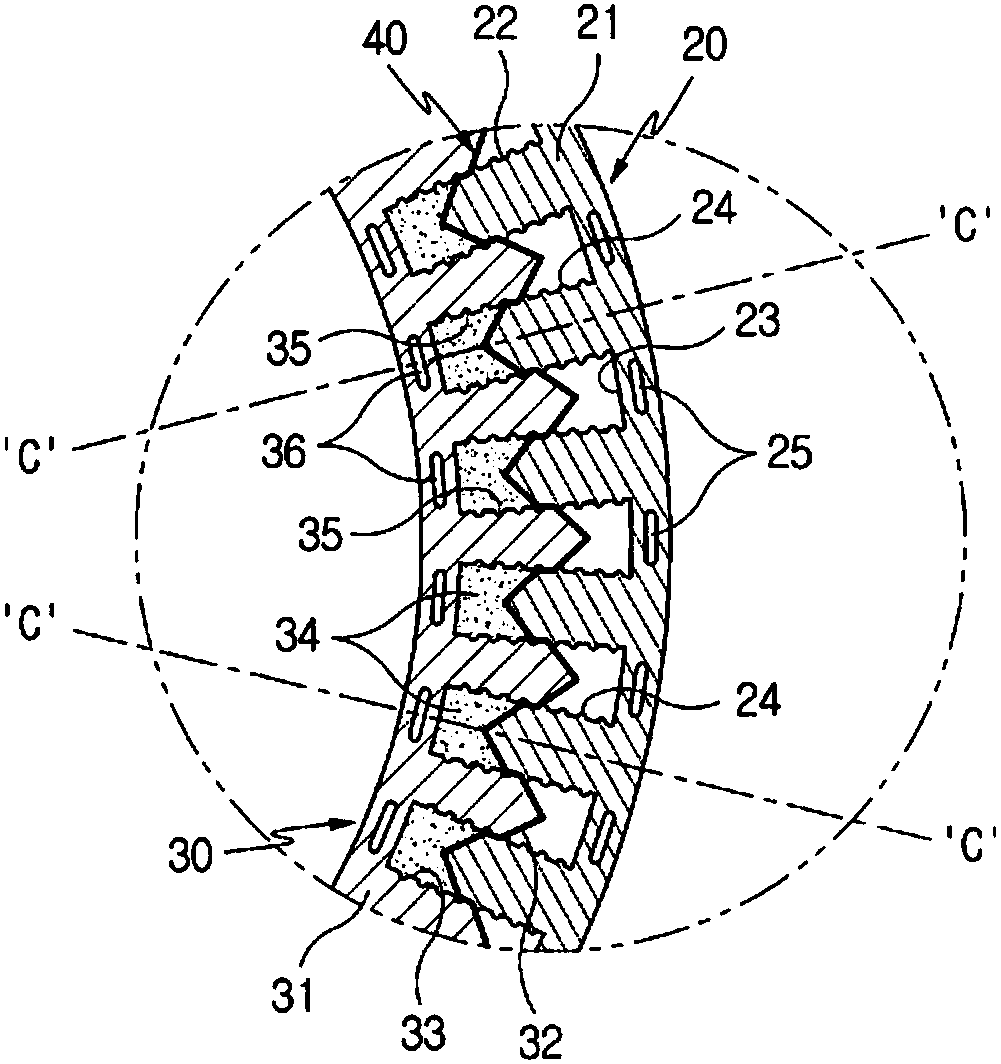

[0047] The characteristics and effects of the plastic guardrail (hereinafter referred to as "guardrail") of the present invention mentioned above or not mentioned will become more clear through the description of the embodiments described below with reference to the accompanying drawings. In the figures, a guardrail according to the invention is indicated by the symbol 10 .

[0048] refer to figure 1 and figure 2 It can be seen that the guardrail 10 according to the present invention is a plate with a longitudinal corrugation and a long length in the transverse direction, and another guardrail 10 of the same structure and form is connected to its end. For the connection, it includes: fastening holes 11, which pass through the ends of the opposite side guardrails 10; bolts 12, which pass through the fastening holes 11 respectively; Two bolts 12 are used to connect the two guardrails 10 together.

[0049] In the figure, reference numerals 14 and 15 are fixing holes and fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com