Safety device for a motor vehicle, having a rotary latch and a pre-latching position and a main latching position

A safety device, a technology of turning the locking fork, applied in the application of locks, electric vehicle locks, vehicle locks, etc., can solve the problem of increasing the total weight of the safety device, the adverse effect of the total weight of the safety device, and the adverse effect of the total weight of the safety device on motor vehicle consumption. and other problems to achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

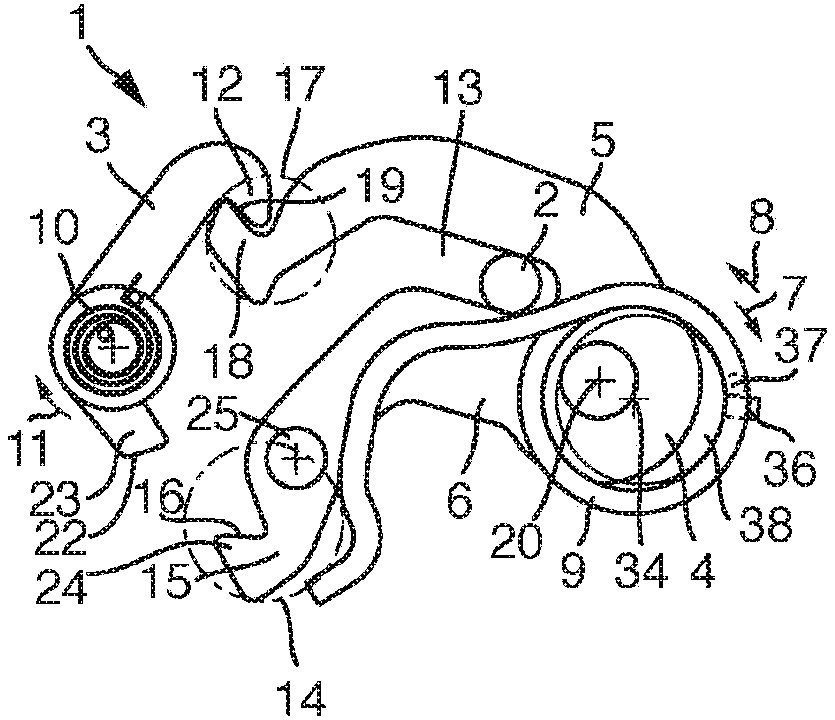

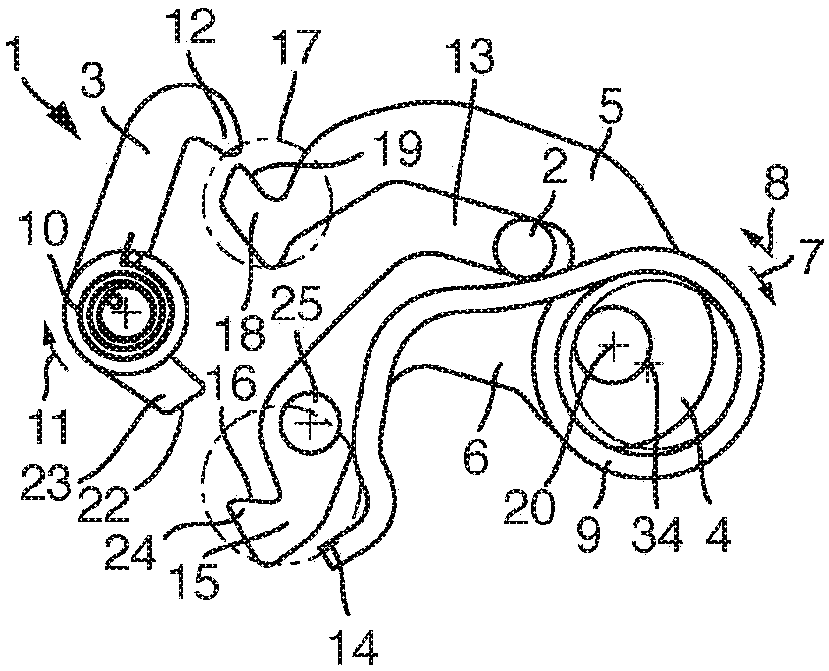

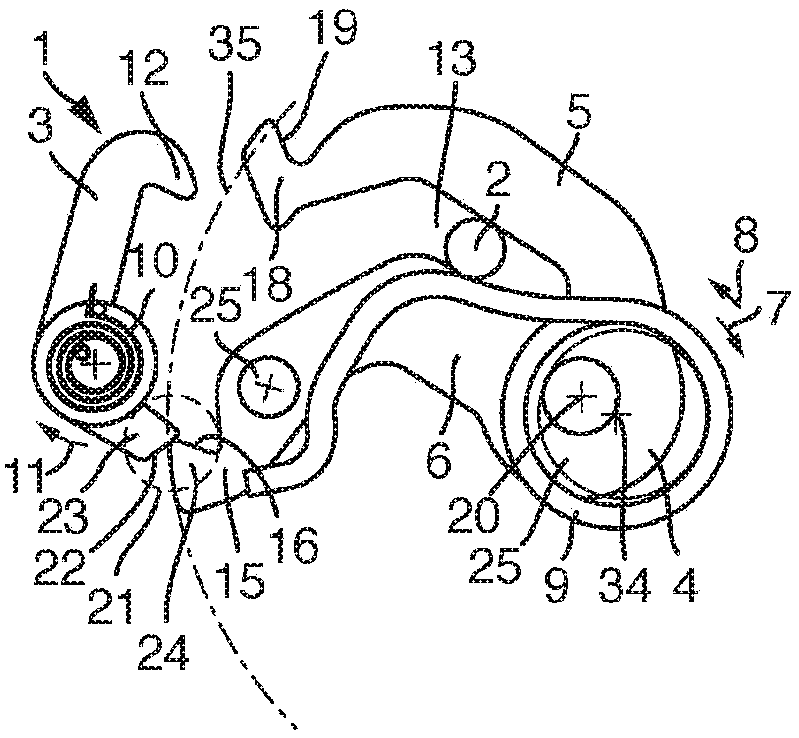

[0036] Figures 1a to 1f and Figure 2a The safety device 1 for a motor vehicle is shown during opening. Figure 1a A safety device 1 is shown with a latch 2 , a pawl 3 and a rotary fork 4 . The rotary locking fork 4 has a load arm 5, a catch arm 6, an opening rotational direction 7, a closing rotational direction 8, a pre-locking position and a main locking position, wherein the rotary locking fork 4 is in Figure 1a Occupy the main locked position. The safety device 1 also has a rotary catch spring 9 which is tensioned in the closing direction 8 of the rotary catch and acts on the rotary catch 4 in the opening rotational direction 7 . The rotary latch spring 9 has a fixed end 36 , which is supported on a stationary support 37 of the safety device 1 . The fixed end 36 advantageously extends to the bearing sleeve 38 and preferably surrounds the bearing sleeve 38 in such a way that the fixed end 36 is immovable relative to the rotational axis 34 of the rotary catch spring 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com