Sensor for a magnetic bearing

A magnetic bearing and sensor technology, which is applied in the field of rotating electrical machines and manufacturing such sensor devices, can solve problems such as adjustment errors, sensor signal distortion of sensor rings, etc., and achieve high reliability, high efficiency, and reliable material connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

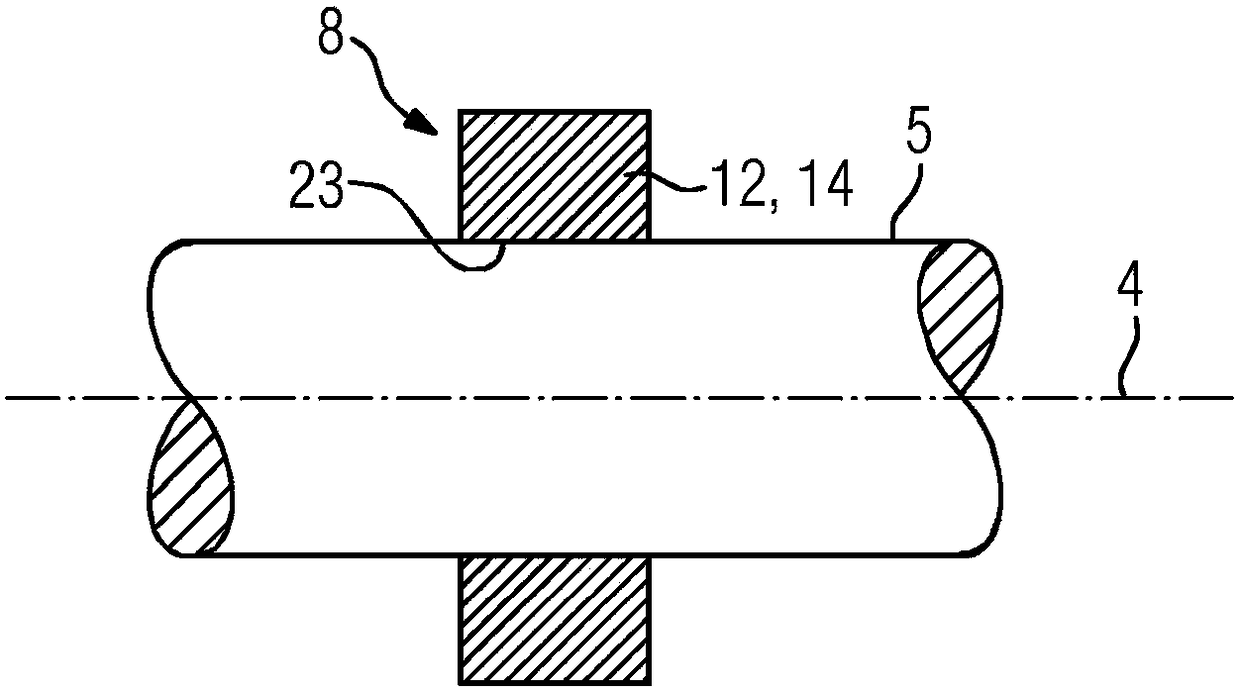

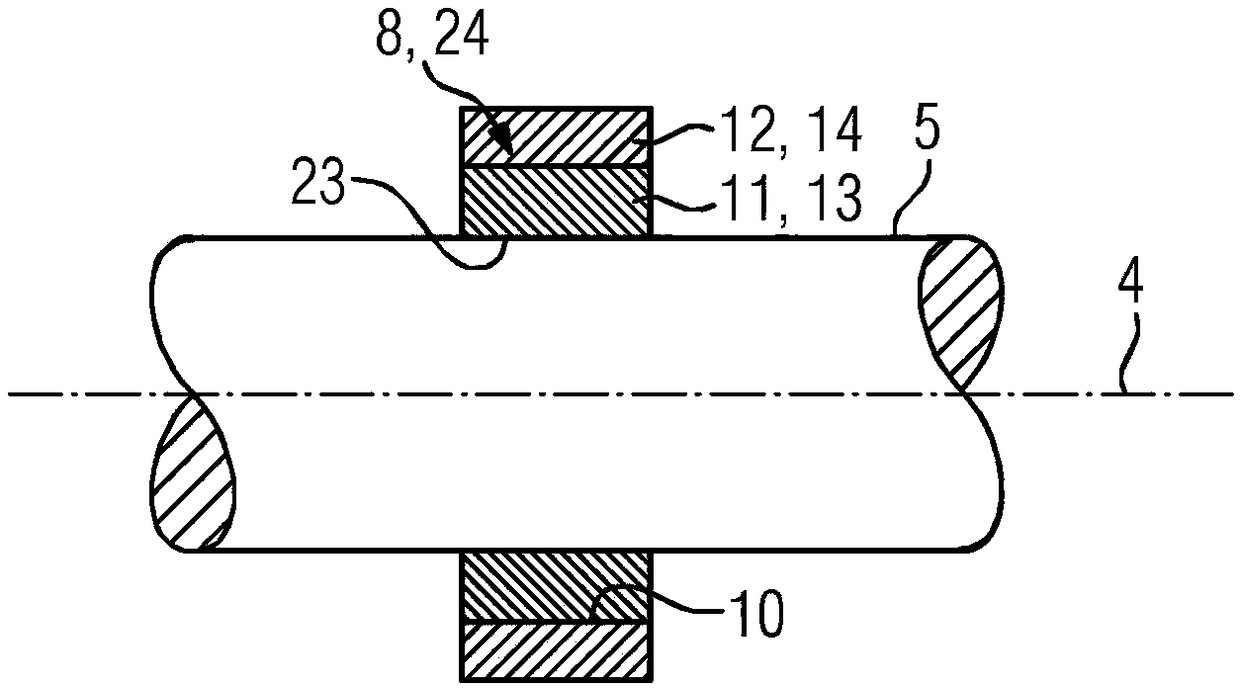

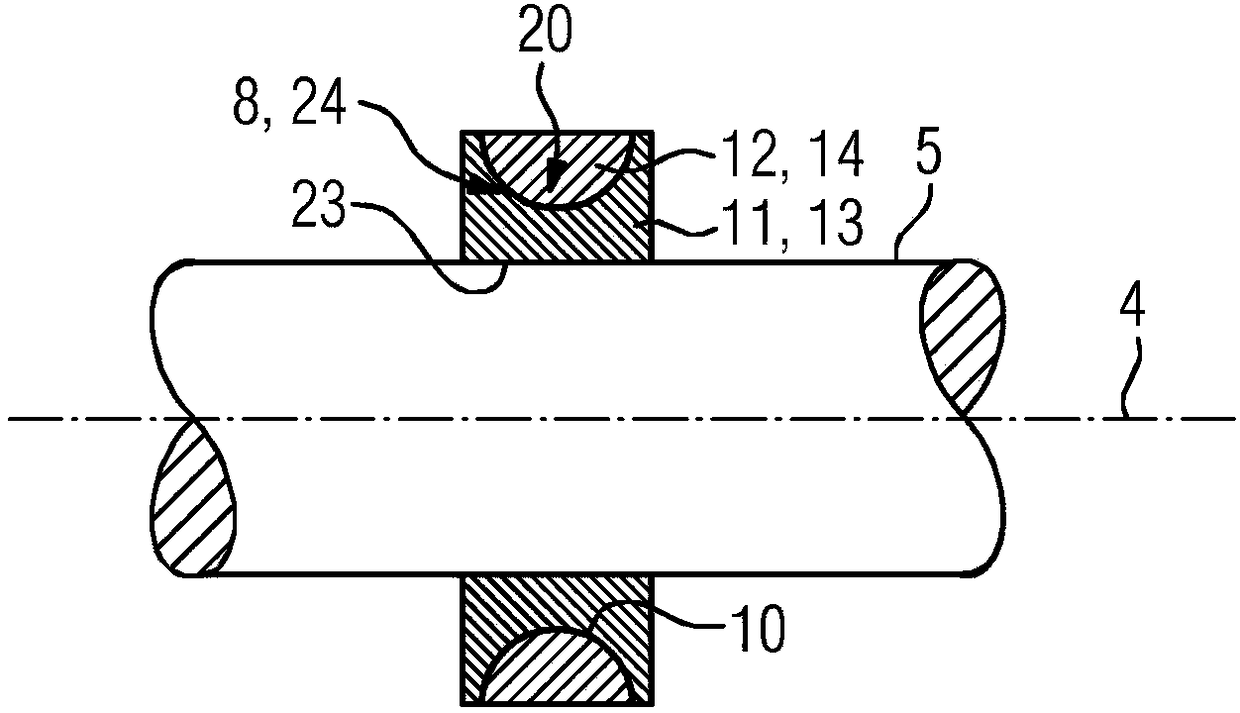

[0037] figure 1 A longitudinal section of the shaft 5 with the sensor ring 8 is shown. Shaft 5 with sensor ring 8 fitted with active magnetic bearings for rotors with demanding rotor dynamics operating on rotating electrical machines with a rotational speed of at least 1000 rpm and a power of at least 1 MW appears.

[0038]In the case of a magnetic bearing of the shaft 5 , the position of the shaft 5 is detected, wherein a magnetic force is exerted on the shaft 5 such that deflection of the shaft 5 is minimized in the magnetic bearing. The input parameter for this adjustment is the position of the shaft 5 , which is measured at a plurality of preferably uniformly distributed positions with movement sensors, for example eddy current sensors. The quality of the measurement signal directly and decisively influences the quality of the control process and the performance of the magnetic bearing. In this case, the sensor ring 8 is used in the sensor arrangement as a sensor target...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com