Turning plate type sorting device, turning plate type sorting system and turning plate type sorting method

A sorting device and sorting system technology, which is applied in the field of flap-type sorting and flap-type sorting devices, can solve the problems of low sorting efficiency, and achieve the requirements of simple structure, reduced shear force, and reduced power source. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

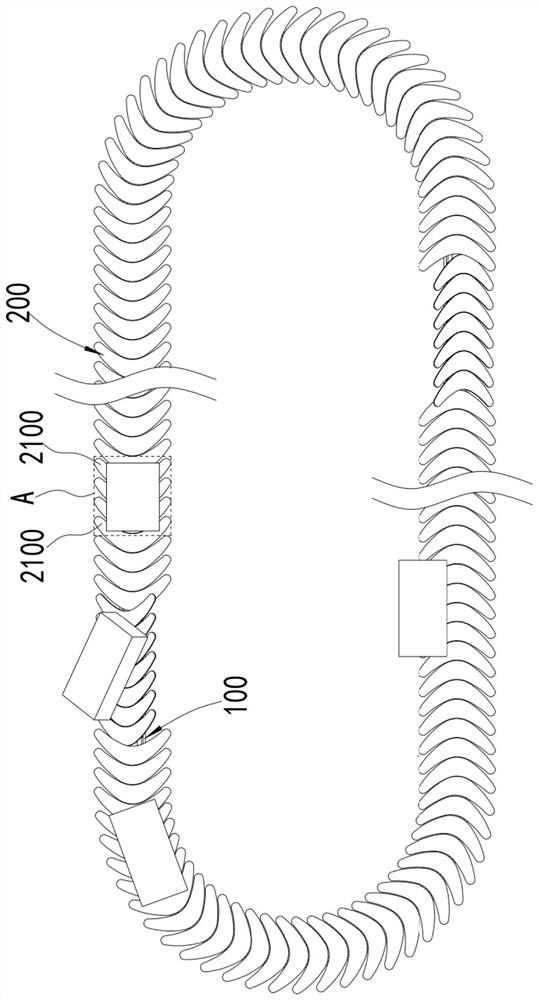

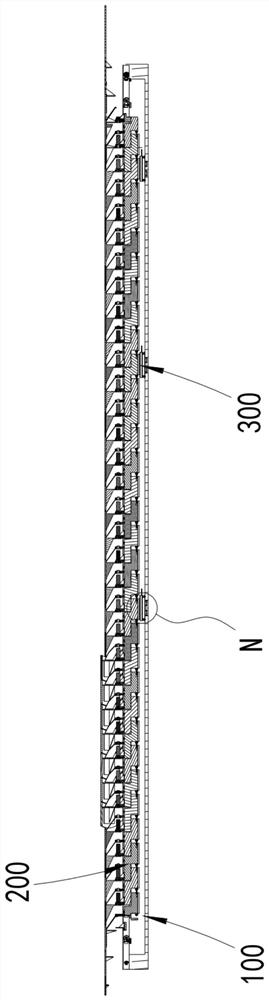

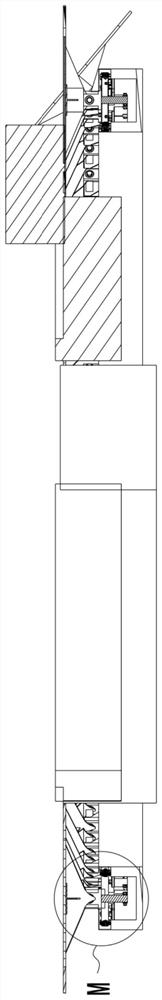

[0058] The flip-type sorting device disclosed by the present invention will be described below in conjunction with the accompanying drawings, as shown in the attached figure 1 - attached image 3 As shown, it includes a circular track 100, the specific structure of the circular track 100 can be designed according to needs, wherein, the shape of the circular track 100 can be set as a regular circle, ellipse or rounded polygon, etc. A regular or irregular shape, in a preferred embodiment, as attached figure 1 As shown, the circular track 100 is in the shape of a waist or a rounded rectangle. Such a circular track shape can effectively reduce the length of the turning section, and is conducive to reserving enough space for adding sorting bays and bag supply tables. as attached Figure 4 As shown, the longitudinal section of the circular track 100 is approximately U-shaped, with its notch facing upwards. The circular track 100 specifically includes a bottom plate 110, and side p...

Embodiment 2

[0090] This embodiment discloses a flip-type sorting system, as shown in the attached Figure 17 As shown, including the panel sorting device 1000 described in Embodiment 1 above, the loop length of the sorting device 1000 can be designed according to the needs of different application scenarios, which is not limited here.

[0091] In some embodiments, it is possible to manually scan the code and place the goods on the turnover trolley of the turnover sorting device 1000, but due to the large size and weight of some goods, it is inconvenient to pack them manually. Although it is possible to manually control the auxiliary equipment such as the balance crane to carry out the upper bag, the efficiency is low. Therefore, as attached Figure 17 As shown, in a more optimal manner, a bag supply platform 2000 and a sorting grid 3000 are also provided on the side of the circular track 200 .

[0092] The bag supply platform 2000 is preferably located in the straight line section of th...

Embodiment 3

[0098] This embodiment discloses a flip-type sorting method, which at least includes the following steps:

[0099] S1, after the goods enter the supply table, at least obtain the weight of the goods and the target route (the position of the sorting grid).

[0100] S2. After the cargo is moved onto the turnover trolley, collect the top image of the turnover trolley through the image acquisition device, analyze and determine the turnover trolley occupied by the cargo, and track the position of the cargo.

[0101] S3, when the goods follow the turnover trolleys and move to the target routing position, the motors of the multiple turnover trolleys where the goods are located are started to drive the multiple turnover panels to flip synchronously and in the same direction to complete the sorting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com