Internal supporting tool system for large workpiece

An internal support, large workpiece technology, applied in the field of processing and assembly, can solve problems such as low efficiency, uncontrollable welding deformation, and inability to improve productivity and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

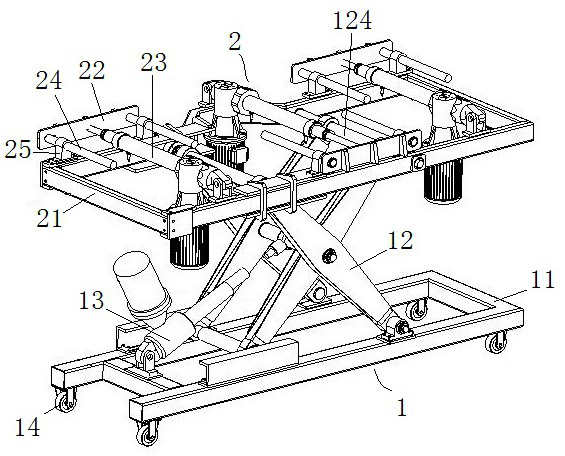

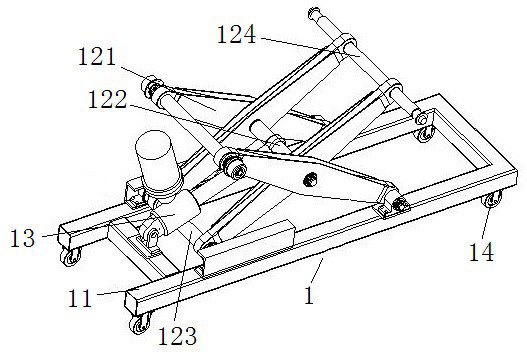

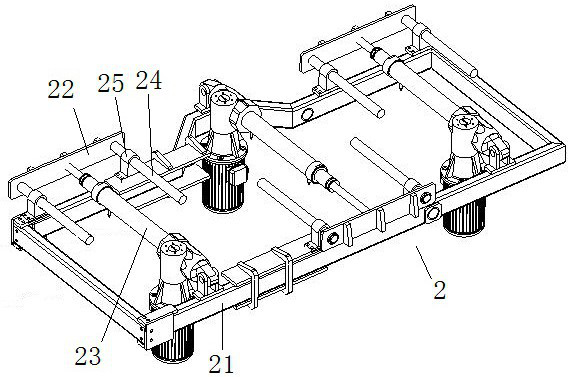

[0016] Such as Figure 1-4 As shown, the present invention is a large workpiece internal support tooling system, including a bottom support part 1 and an upper support positioning part 2 arranged inside the welding workpiece 3. The bottom support part 1 includes a bottom support frame 11, a scissor fork lifting mechanism 12. Bottom electric push rod 13, the bottom of the bottom support frame 11 is equipped with walking wheels 14, which is convenient to move during operation. The upper support positioning part 2 includes an upper support frame 21, a support plate 22, and an upper electric push rod 23. The scissor-fork lifting mechanism 12 includes two sets of scissor-fork connecting arms 121 symmetrically arranged on the bottom support frame 11. The upper end of one side of the connecting arm 121 is slidably installed on the upper support frame 21 through the moving shaft 123, and the lower end of one side of the two groups of scissor fork connecting arms 121 is slidably instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com