Gantry lift with follow-through end plate

A gantry type and lift technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of low efficiency, unstable support reliability, unfavorable car chassis support, etc., to achieve increased support reliability and large support area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

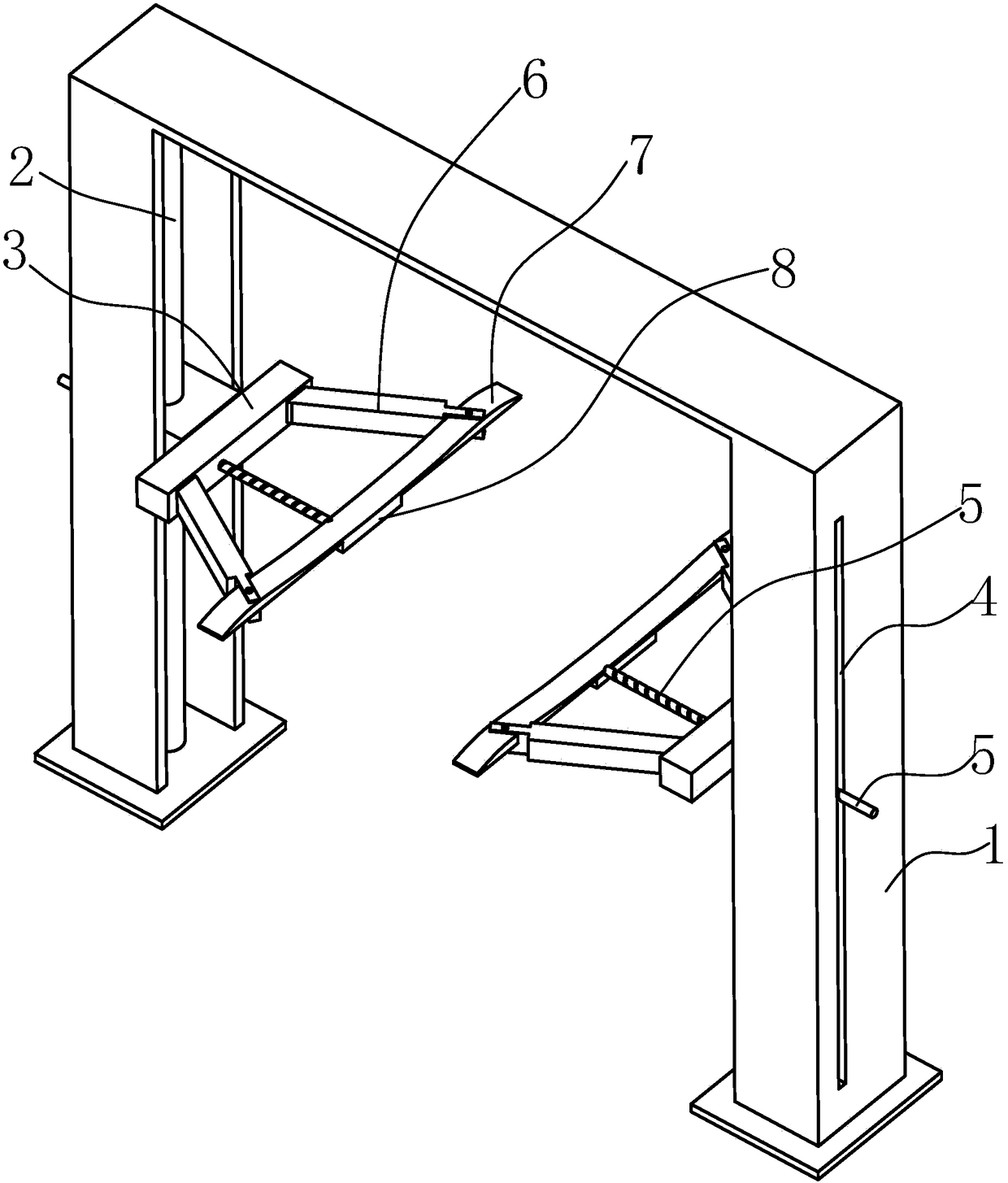

[0015] Such as figure 1 As shown, the gantry lift with follow-up end plate 7 includes two stands 1, each of which is provided with a lifting screw 2, and the lifting screws 2 are equipped with lifting The base frame 3 and the lower end of the lifting screw 2 are connected to a motor for driving the corresponding lifting screw 2 through a gear connection, and a beam is connected to the upper end of the stand 1 together.

[0016] The side of the stand 1 away from the other stand 1 is provided with a vertical strip hole 4, and a horizontal push screw 5 that can move up and down in the strip hole 4 is pierced in the strip hole 4. , the two ends of the lifting base frame 3 away from the corresponding stand 1 are fixedly connected with a lifting arm 6, and the lifting arm 6 is a secondary te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com