A self-rotating aeration stirring device

A technology of ventilated stirring and stirring mechanism, which is applied in the field of stirring various substances and ventilated stirring devices. It can solve the problems of separate power source, fixed structure, and single function, and achieves simple cleaning and maintenance, improved compactness, and great flexibility. and general effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

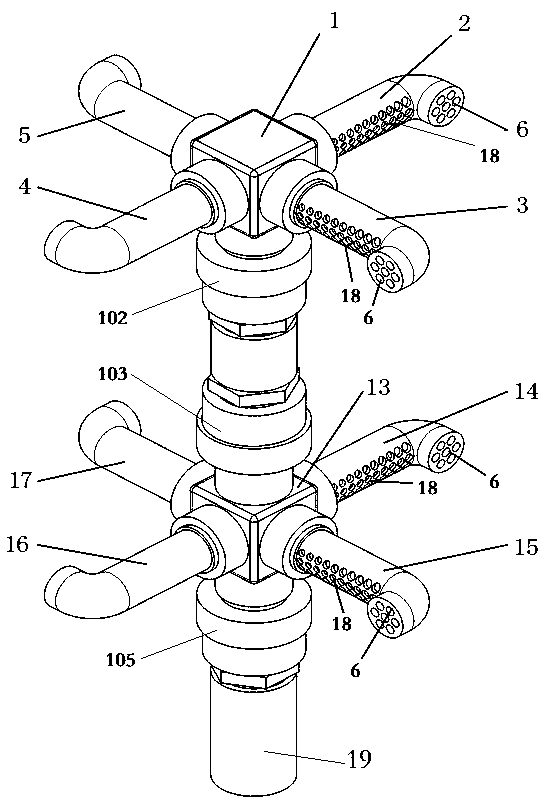

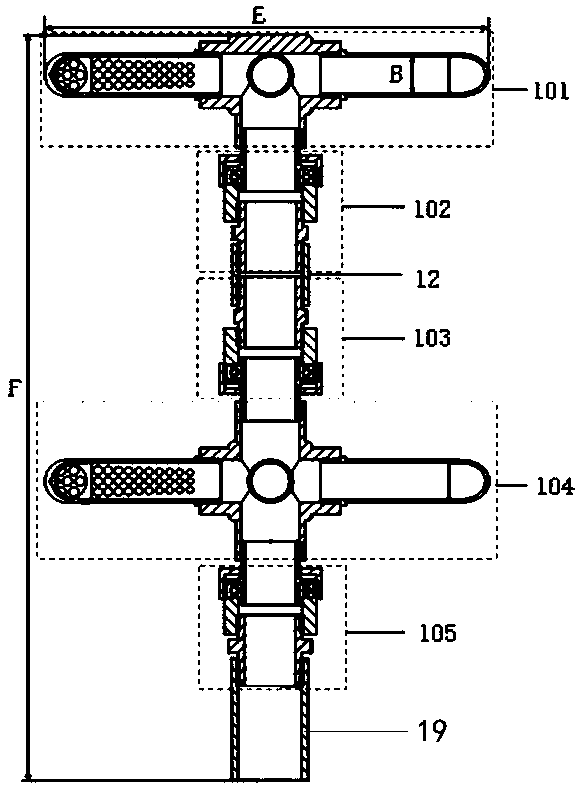

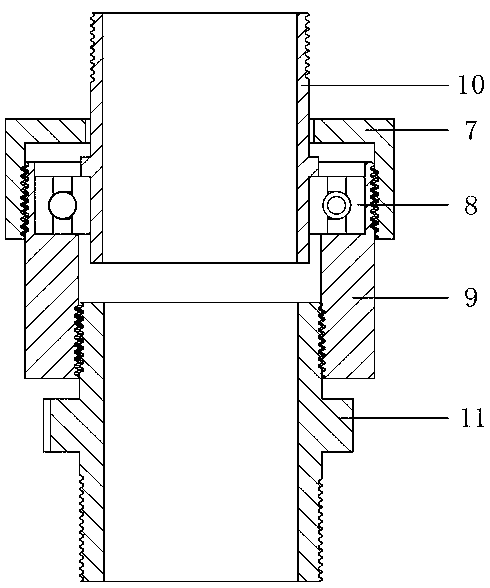

[0020] see Figure 1 to Figure 2 , the present invention from top to bottom is the primary stirring mechanism 101, the first rotating assembly 102, the primary connecting pipe 12, the second rotating assembly 103, the secondary stirring mechanism 104, the third rotating assembly 105, and the secondary connecting pipe 19 . All connecting pipes, rotating components and stirring mechanisms have the same central axis and are all connected inside.

[0021] The primary stirring mechanism 101 is composed of four rotating blades of the five-way body 1 . The four rotating blades are all hollow short tubes, and are respectively the first rotating blade 2 , the second rotating blade 3 , the third rotating blade 4 and the fourth rotating blade 5 . The five-way body 1 is a square structure with a cavity inside, and through holes are processed on its four sides and a bottom surface. The diameters of the through holes on the four sides are the same, and each side is fixed and sealed throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com