Single pile jacking and slipping boarding process

A sliding and single-pile technology, which is applied to ship accessories, passenger handling equipment, ships, etc., can solve the limitations of single-pile foundation production, hoisting and shipping, the production speed cannot meet the market demand, and the single-pile foundation is too heavy To achieve the effect of stable and controllable shipping process, reduce infrastructure construction of final assembly site, and strong wave resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0035] A single pile jacking and sliding boarding process of the present invention comprises the following steps:

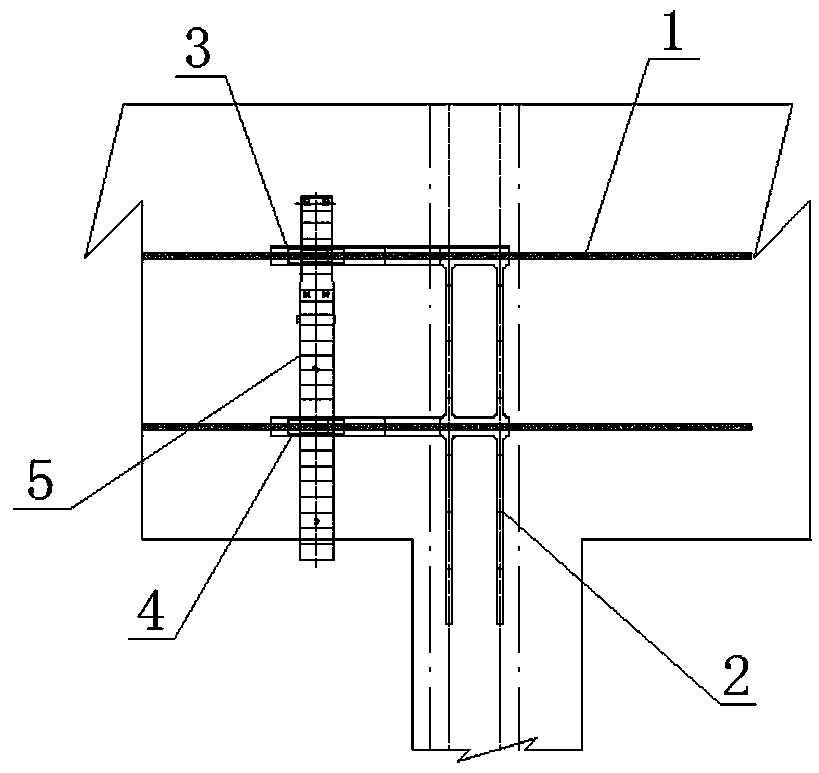

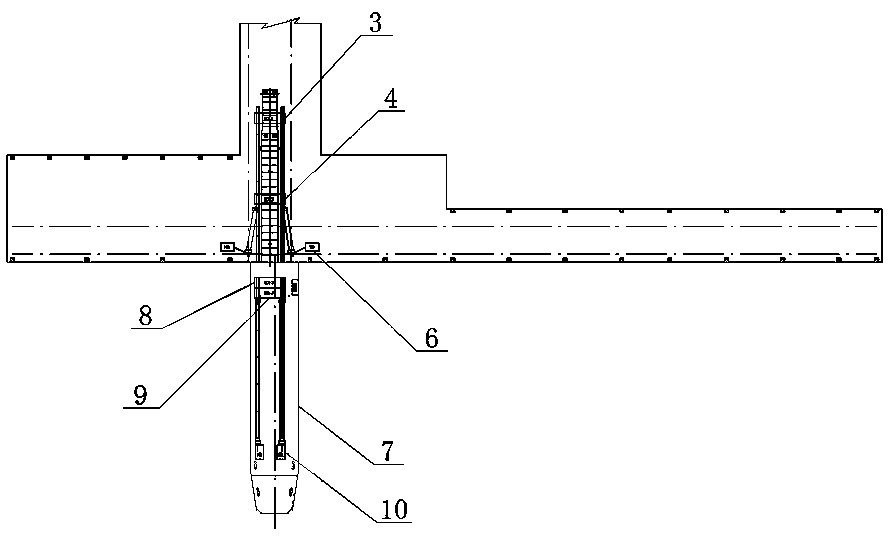

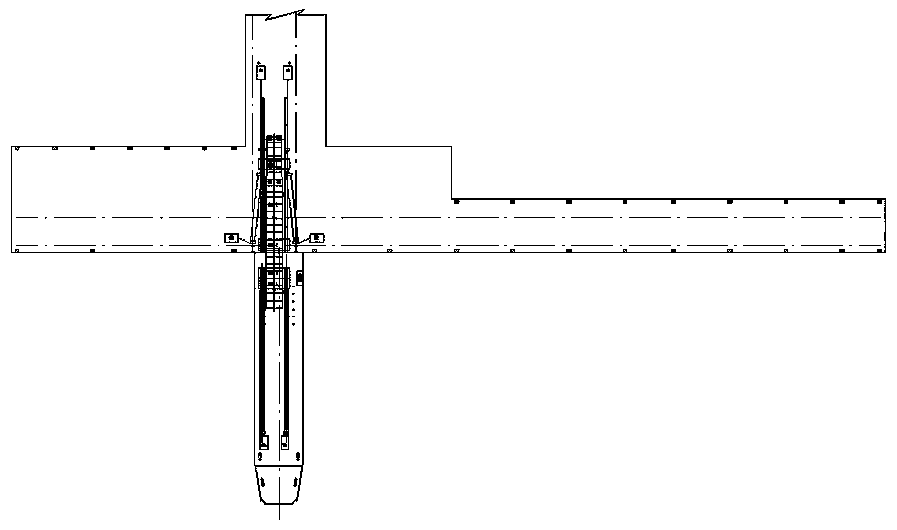

[0036] Step 1: If figure 1 As shown, the traversing track 1 and the traversing track 2 are set on the wharf, the traversing track is set parallel to the edge of the wharf, the vertical track is set perpendicular to the traversing track and one end of the vertical track intersects the traversing track, and the vertical track The other end is set on the shore of the pier. The bottom of the skid jacking device is a smooth plane, and the skid jacking device is slidably arranged on the traverse track and the longitudinal track. No. 1 slip jacking device 3 and No. 2 slip jacking device 4 are installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com