Environment-friendly sewage treatment device adopting flocculant

An environmental protection treatment and sewage device technology, applied in the direction of flocculation/sedimentation water/sewage treatment, sedimentation treatment, water/sewage treatment, etc., can solve the problems that affect the efficiency of sewage treatment, easy to block the grid, time-consuming and labor-intensive, etc., to achieve purification Significant effect, easy operation, and efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

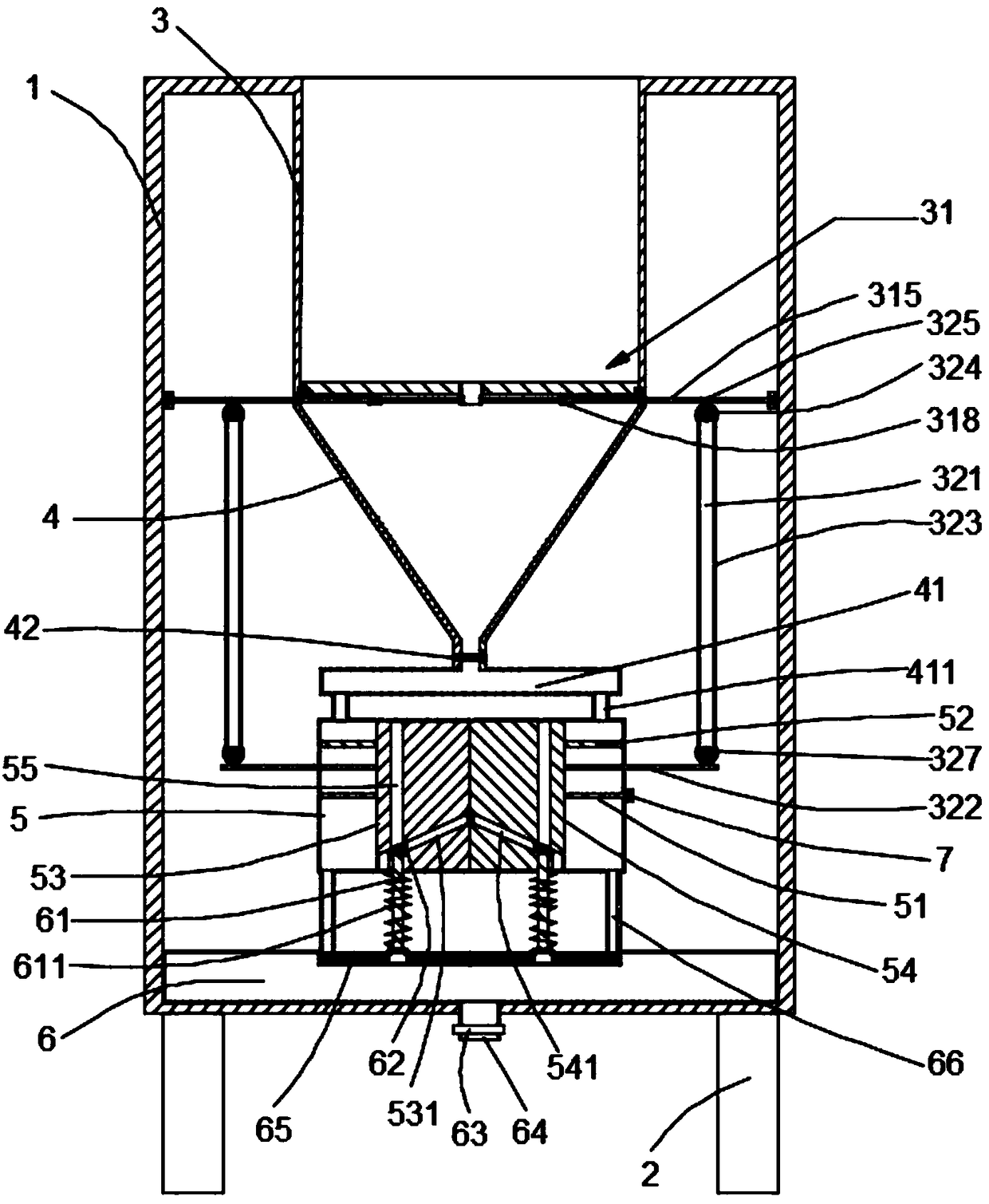

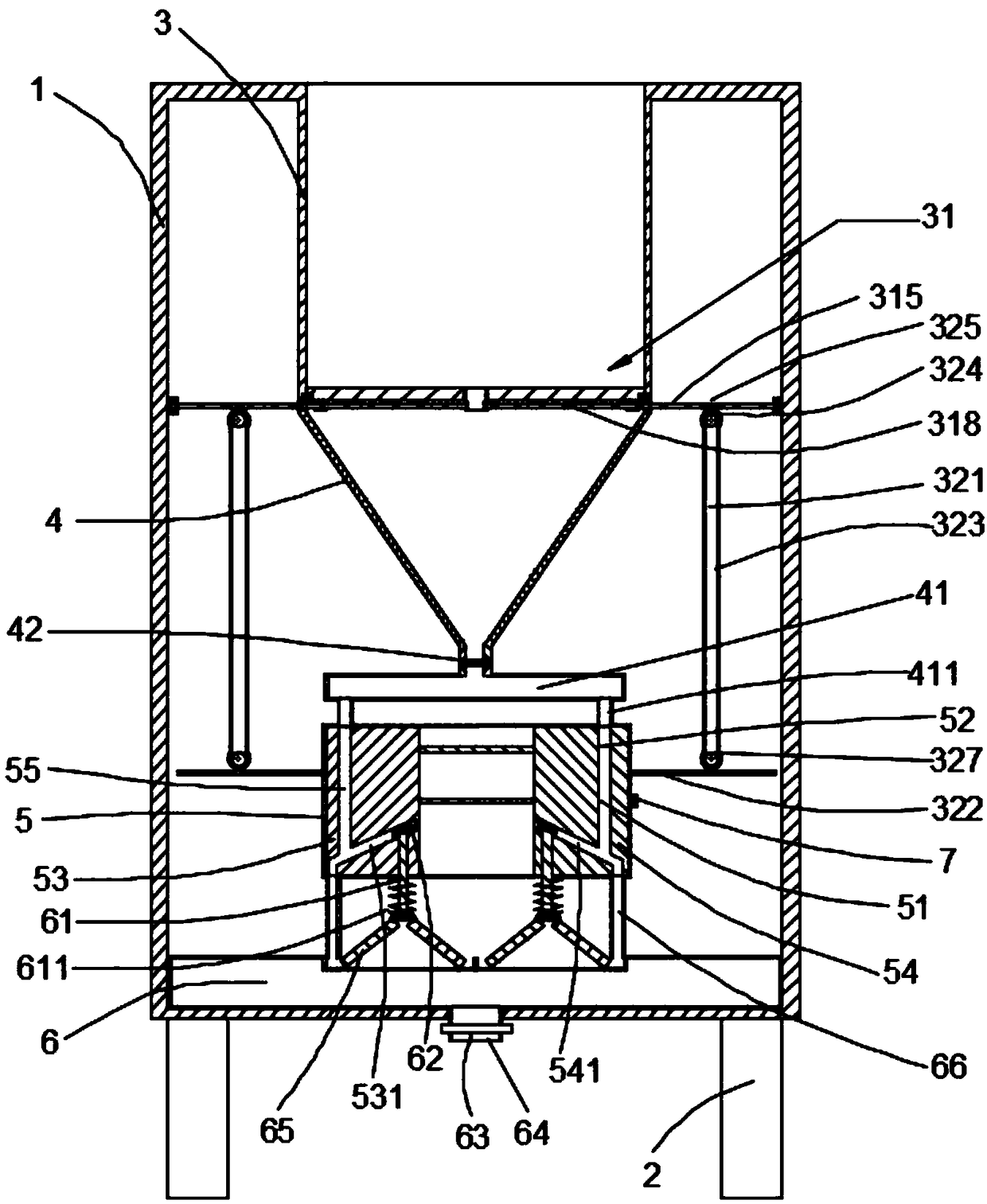

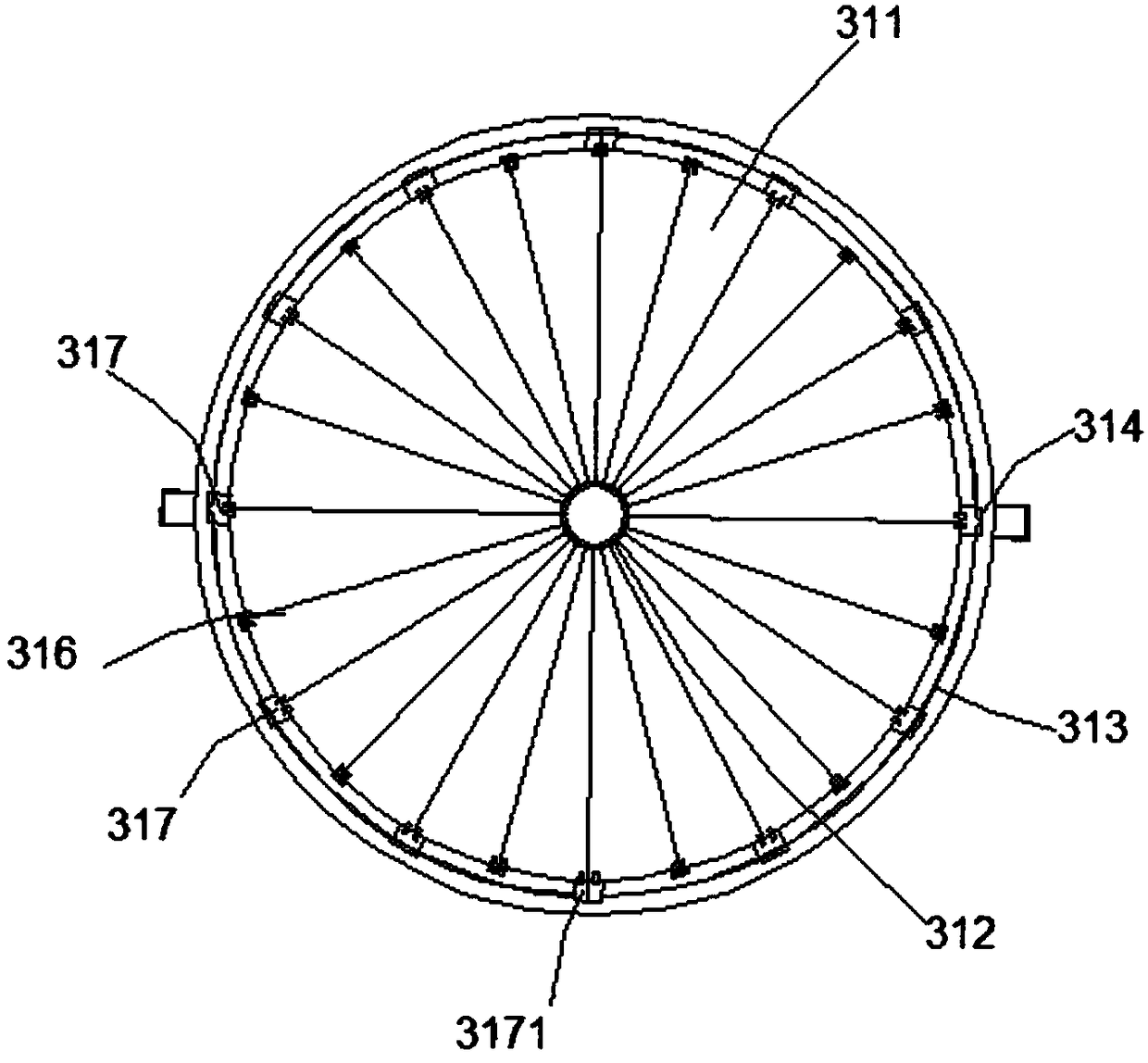

[0028] Such as Figure 1-6 As shown, this embodiment provides an environmentally friendly sewage treatment device using a flocculant, including a frame 1 and a support leg 2 at the bottom thereof. The inside of the frame 1 is provided with water storage chambers 3, which are connected in sequence from top to bottom. The conical sedimentation tank 4, the sliding chamber 5 and the sedimentation chamber 6, the bottom of the water storage chamber 3 and the top of the conical sedimentation tank 4 are isolated by a folded isolation plate 31, and the sliding chamber 5 is provided with a left slide The screw rod 51 and the slide bar 52 that are extended to the left and right of the sliding block 53 and the right sliding block 54, the screw rod 51 is respectively connected with the left sliding block 53 and the right sliding block 54 through the threads in opposite directions, and one end of the screw rod 51 is driven by the motor 7 connection, the left sliding block 53 and the right s...

Embodiment 2

[0030] Such as Figure 1-6 As shown, this embodiment provides an environmentally friendly sewage treatment device using a flocculant, including a frame 1 and a support leg 2 at the bottom thereof. The inside of the frame 1 is provided with water storage chambers 3, which are connected in sequence from top to bottom. The conical sedimentation tank 4, the sliding chamber 5 and the sedimentation chamber 6, the bottom of the water storage chamber 3 and the top of the conical sedimentation tank 4 are isolated by a folded isolation plate 31, and the sliding chamber 5 is provided with a left slide The screw rod 51 and the slide bar 52 that are extended to the left and right of the sliding block 53 and the right sliding block 54, the screw rod 51 is respectively connected with the left sliding block 53 and the right sliding block 54 through the threads in opposite directions, and one end of the screw rod 51 is driven by the motor 7 connection, the left sliding block 53 and the right s...

Embodiment 3

[0032] Such as Figure 1-6As shown, this embodiment provides an environmentally friendly sewage treatment device using a flocculant, including a frame 1 and a support leg 2 at the bottom thereof. The inside of the frame 1 is provided with water storage chambers 3, which are connected in sequence from top to bottom. The conical sedimentation tank 4, the sliding chamber 5 and the sedimentation chamber 6, the bottom of the water storage chamber 3 and the top of the conical sedimentation tank 4 are isolated by a folded isolation plate 31, and the sliding chamber 5 is provided with a left slide The screw rod 51 and the slide bar 52 that are extended to the left and right of the sliding block 53 and the right sliding block 54, the screw rod 51 is respectively connected with the left sliding block 53 and the right sliding block 54 through the threads in opposite directions, and one end of the screw rod 51 is driven by the motor 7 connection, the left sliding block 53 and the right sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com