Unbalanced force testing method for curve beam bridge swiveling construction of high-speed railway

A technology for high-speed railways and testing methods, applied in static/dynamic balance testing, machine/structural components testing, measuring devices, etc., can solve problems that affect the normal force of the structure, and achieve high safety and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

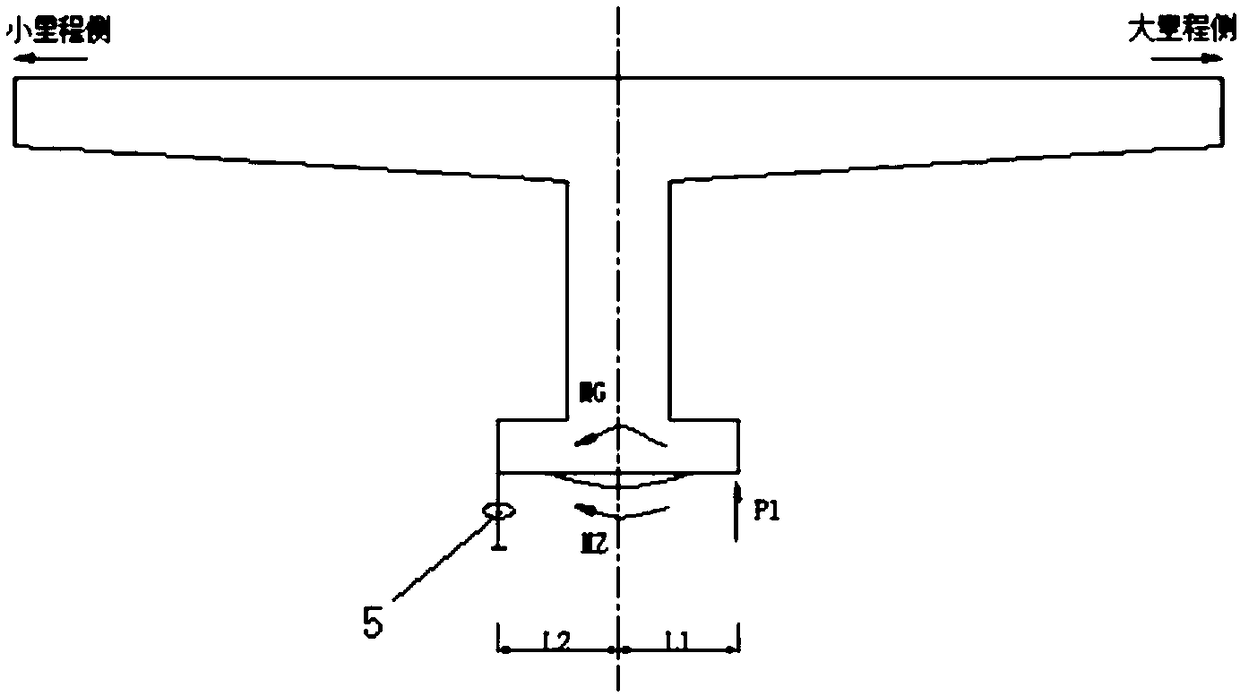

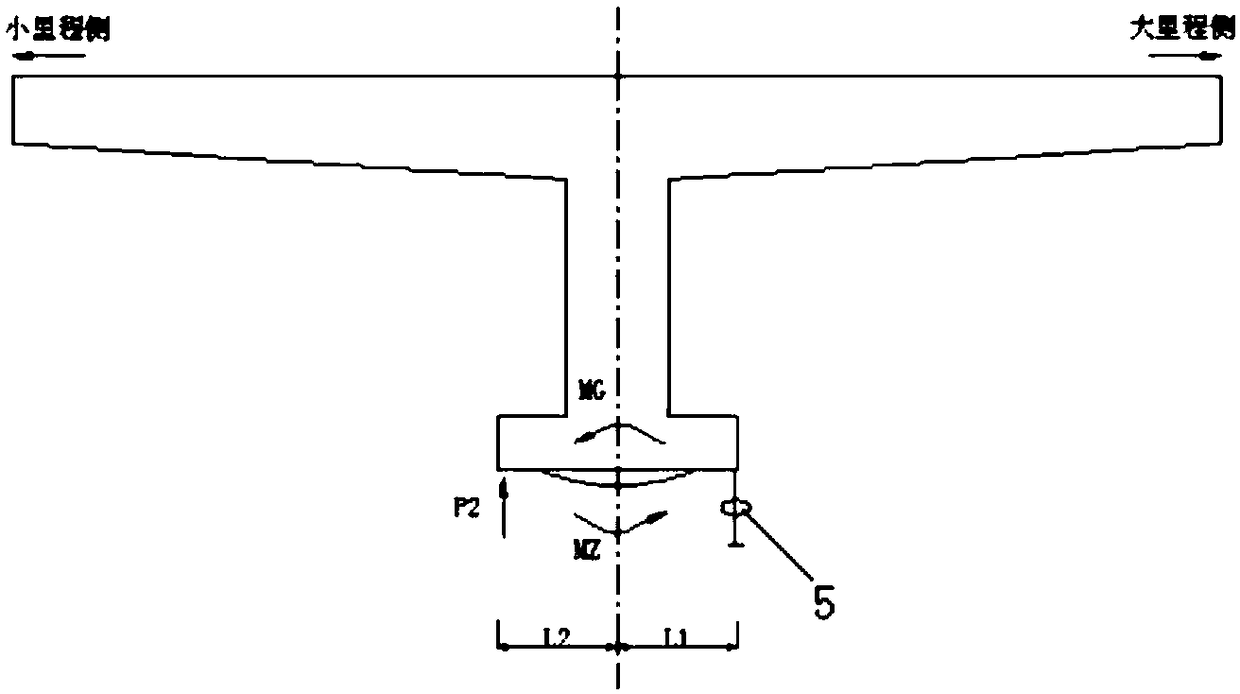

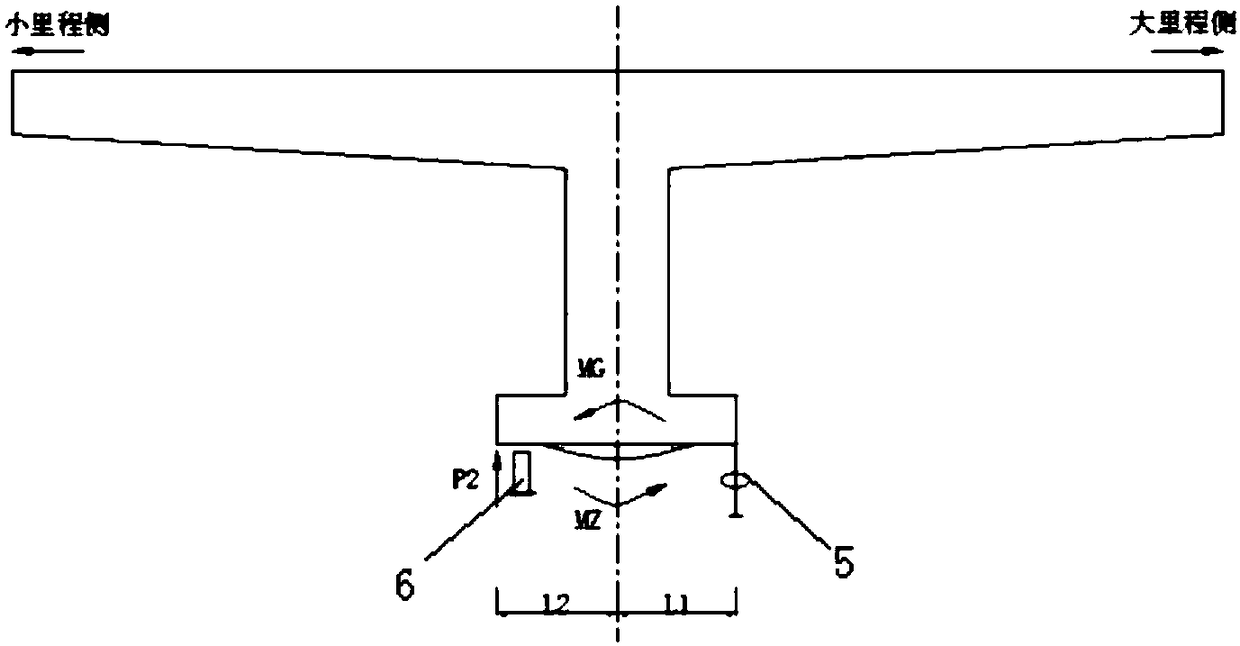

[0083] (1) Vertical weighing

[0084] The 45# pier T structure also has a large unbalanced moment due to the 1.53% slope in the longitudinal direction of the bridge. At the beginning of the test, after cutting off the temporary supporting I-beam, it was found that the side with a large mileage was on the ground, and the unbalanced moment was greater than the frictional moment. According to theoretical calculation, the counterweight should be 23t within the range of 29m~31m from the center of the pier to the maximum mileage. After the first weighing, the actual counterweight is 18.4t in the range of 29m to 31m in the long-distance direction. After the counterweight, the T structure of the 45# pier reaches balance, and all the legs are off the ground. At this time, the unbalanced moment is smaller than the frictional moment. After the counterweight is completed, repeat the weighing. See Table 4-2 for the reweighing results, and the load and displacement curves are as follows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com