Car sleeve outer wall grinding device

A technology for automobiles and sleeves, which is used in grinding/polishing safety devices, grinding machines, grinding/polishing equipment, etc., can solve the problems that the grinding ring and the sleeve cannot be in contact, the debris is not easily discharged, and the grinding effect is not good. Achieve the effect of saving cleaning realization and cost, facilitating collection, and better grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below by means of specific embodiments:

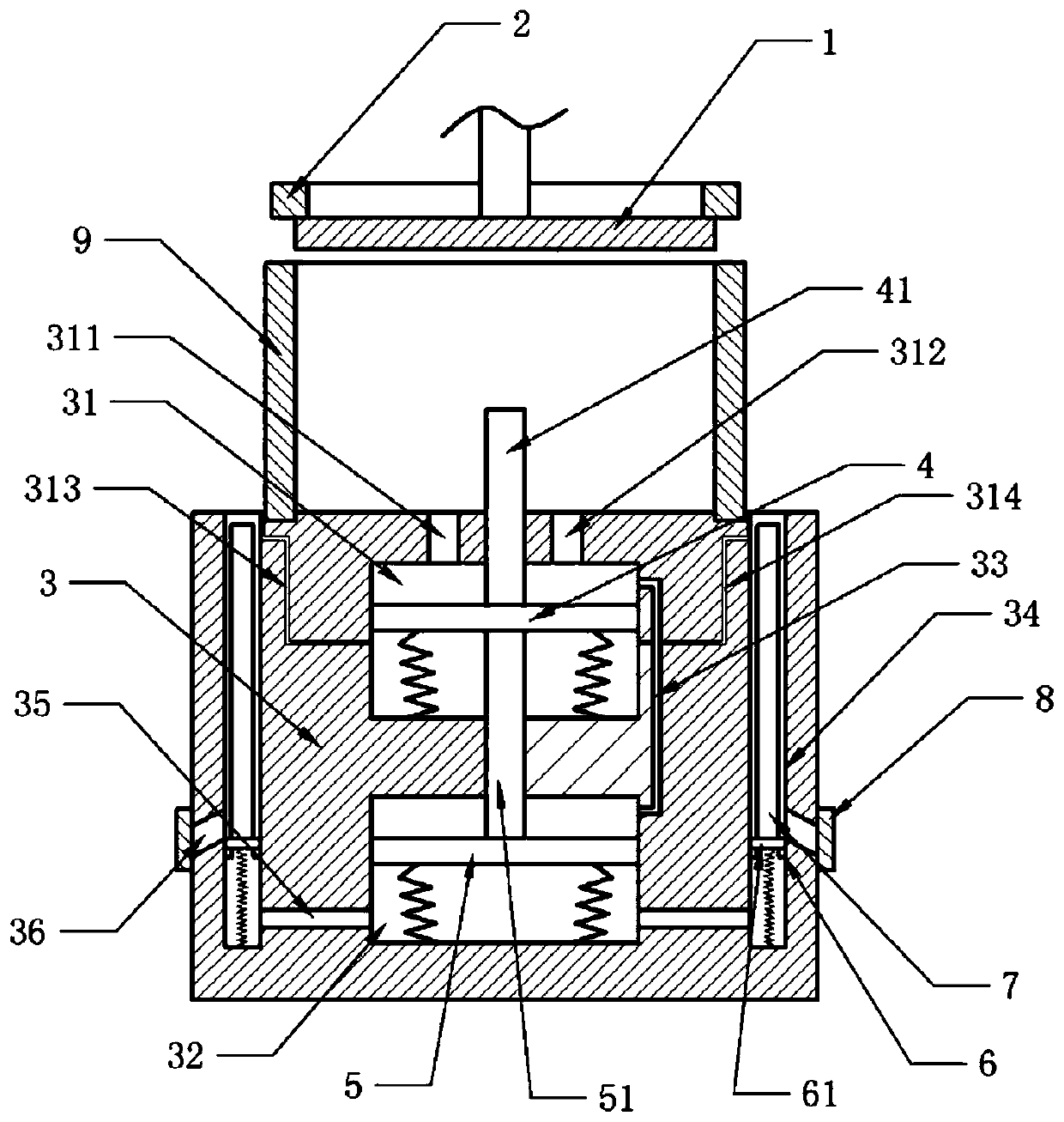

[0037] The reference signs in the drawings of the description include: grinding head 1, counterweight 2, base 3, first cavity 31, dust suction port 311, exhaust port 312, air inlet pipe 313, air outlet pipe 314, second air outlet Cavity 32, air guide hole 33, moving groove 34, communication hole 35, dust outlet 36, first piston 4, first push rod 41, second piston 5, second push rod 51, limit block 6, support plate 61 , Grinding cylinder 7, block 8, sleeve 9.

[0038] Such as figure 1 As shown, the motorcycle sleeve outer wall grinding device includes a frame and a base 3 located below the frame. The frame is provided with a cylinder, and the push rod of the cylinder is provided with a grinding head 1, and the push rod of the cylinder is located on the The top of the grinding head 1 is sheathed with an annular counterweight 2 that matches the sleeve 9, and the counterwei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com