Assembling tool for secondary equipment modules of prefabricated cabin

A technology for secondary equipment and assembly tooling, applied in workshop equipment, manufacturing tools, workbenches, etc., to solve problems such as low assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

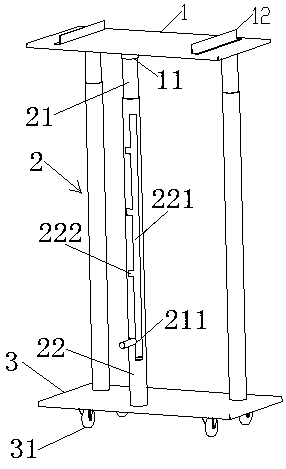

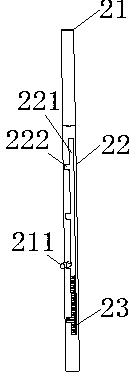

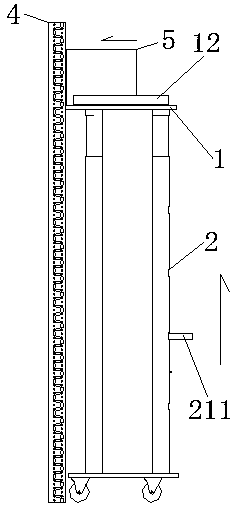

[0024] Specific embodiment 1 of the prefabricated cabin secondary equipment module assembly tooling of the present invention, as Figure 1 to Figure 4 As shown, the assembly tooling of the secondary equipment module of the prefabricated cabin includes a base 3, an installation platform 1 arranged above the base 3, and a height adjustment mechanism 2 arranged between the base 3 and the installation platform 1. The height adjustment mechanism 2 includes a guide structure, The installation platform 1 and the base 3 guide and move in the up and down direction through the guide structure, and have a plurality of installation positions corresponding to the installation positions of the secondary equipment modules on the prefabricated cabin frame 4. The positioning structure of the installation platform 1 is locked and fixed at the installation position. Durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com