Heat-sealing device for plastic bag or plastic tube

A heat-sealing device, a technology for plastic tubes, applied in the direction of tubular items, other household appliances, household appliances, etc., can solve the problems of reducing the heat-sealing speed, affecting the shape of plastic bags or plastic tubes, tearing plastic films, etc. Standard, avoid temperature loss, improve the effect of heat sealing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

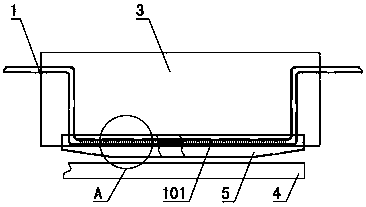

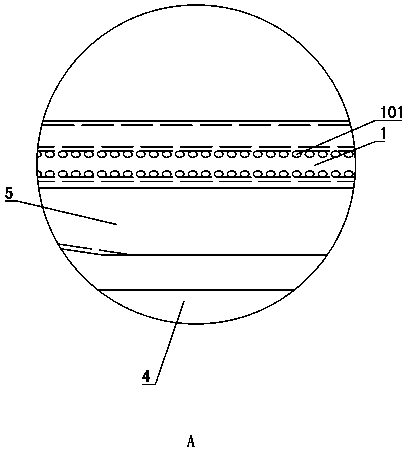

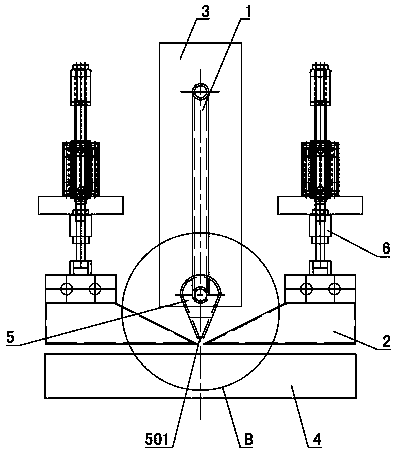

[0030] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with the attached Figure 1~4 The present invention will be further described.

[0031] A heat-sealing device for plastic bags or plastic pipes, comprising an air equalizing box 5 and a platform 4 arranged at intervals on the side of the air equalizing box 5, an air outlet 501 is arranged on the side of the air equalizing box 5 close to the platform 4, and the air outlet 501 is parallel to the platform 4 Set, the air equalizing box 5 is connected with the hot air pipe 1. The air outlet 501 is arranged on the side near the platform 4 of the air equalizing box 5 of this plastic bag or plastic pipe heat sealing device, and the hot air in the hot air pipe 1 is evenly sprayed out along the air outlet after the air equalizing box 5, and the plastic film is to be sealed The side is arranged between the platform 4 and the air outlet 501, and the heat sealing of the plastic film can be realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com