Special telescopic handbarrow for installation rails of transformer equipment

A technology for equipment installation and handling tools, applied in the directions of transportation and packaging, manual conveying devices, etc., can solve problems such as difficulty, large manpower and time, and injured personnel, so as to shorten the construction time, reduce the handling time, and improve the work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

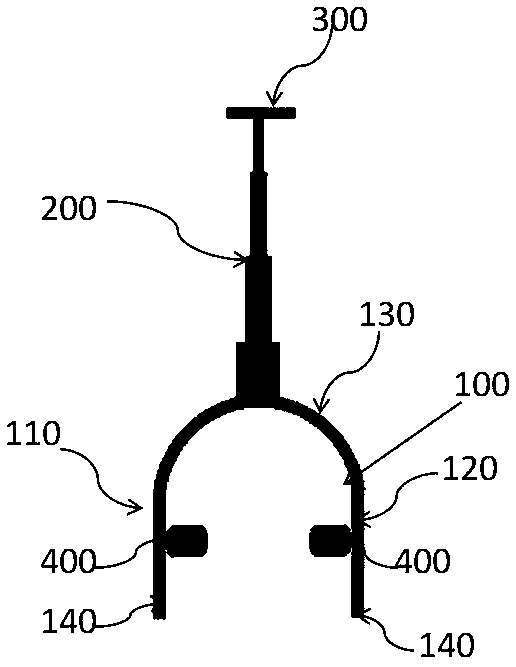

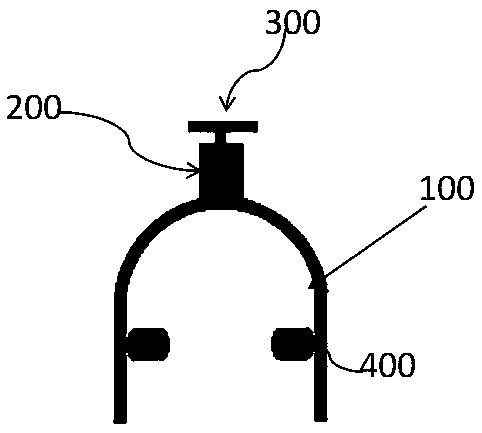

[0021] Such as Figure 1~2 As shown, a special transport tool for the installation track of retractable transformer-like equipment includes a vertical body 100, a first connecting rod 200, and a handle 300. The first connecting rod 200 is connected to the upper end of the vertical body 100, and The lower end is provided with a support point 140 for supporting the ground, and the handle 300 is connected with the first connecting rod 200 .

[0022] Wherein, the first connecting rod 200 is an adjustable and telescopic multi-stage bushing structure, preferably a four-stage bushing in this implementation.

[0023] The inner wall of the X-shaped main body 100 is provided with two pulleys 400, opposite between the two pulleys 400, and the size between the two pulleys 400 is matched with the rail 500, so that the two pulleys 400 can just pass through the rails and will not Slip off the rails.

[0024] Wherein, the X-shaped main body 100 comprises a left support rod 110, a right supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com