Clamping-strap-length adjustable hose clamp

A technology of cuffs and throat cuffs, applied in the field of throat cuffs, can solve problems such as inconvenience and increase in production cost, and achieve the effect of convenient connection and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

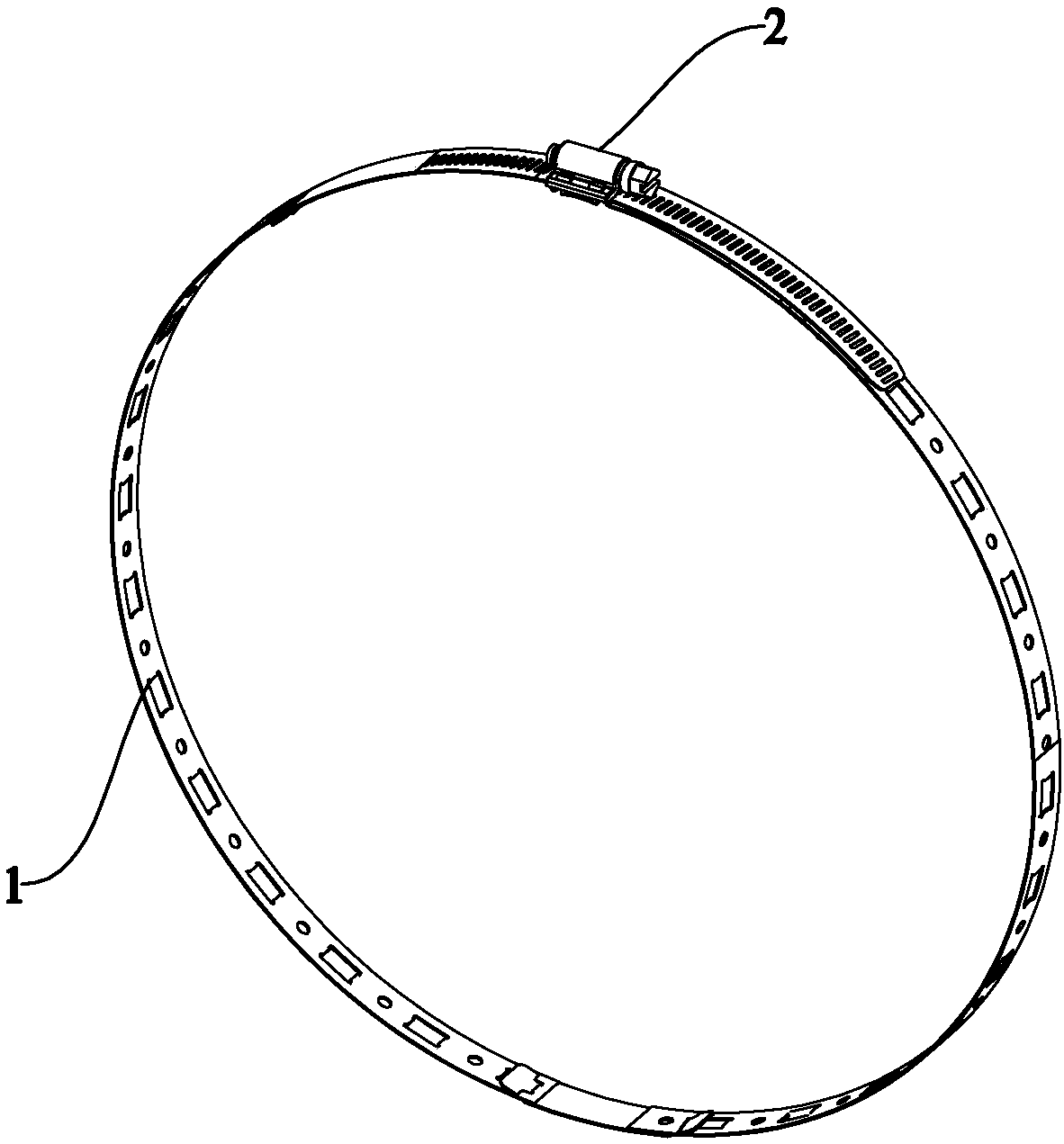

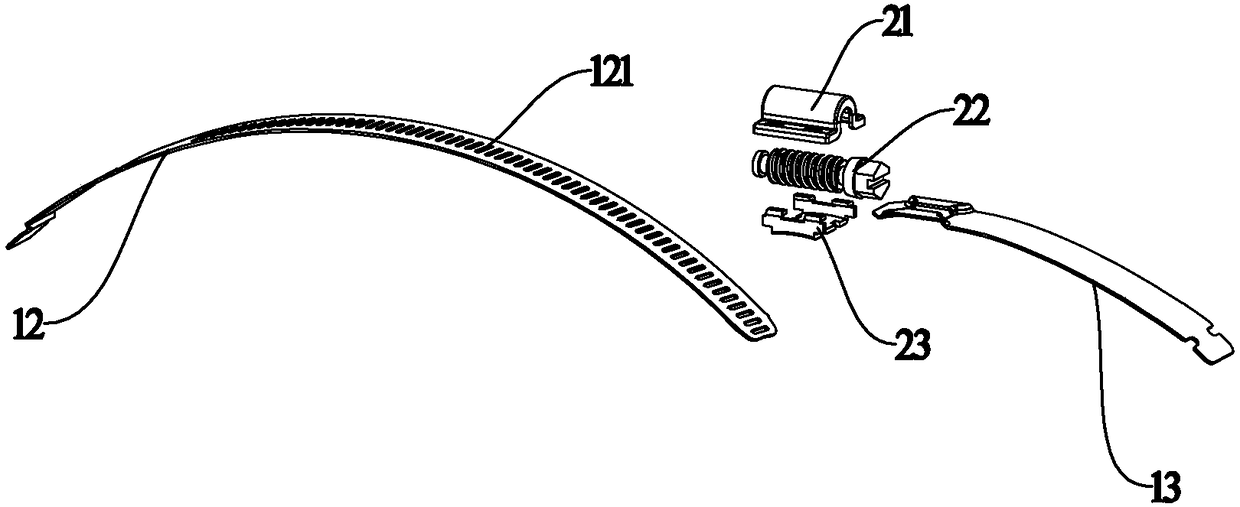

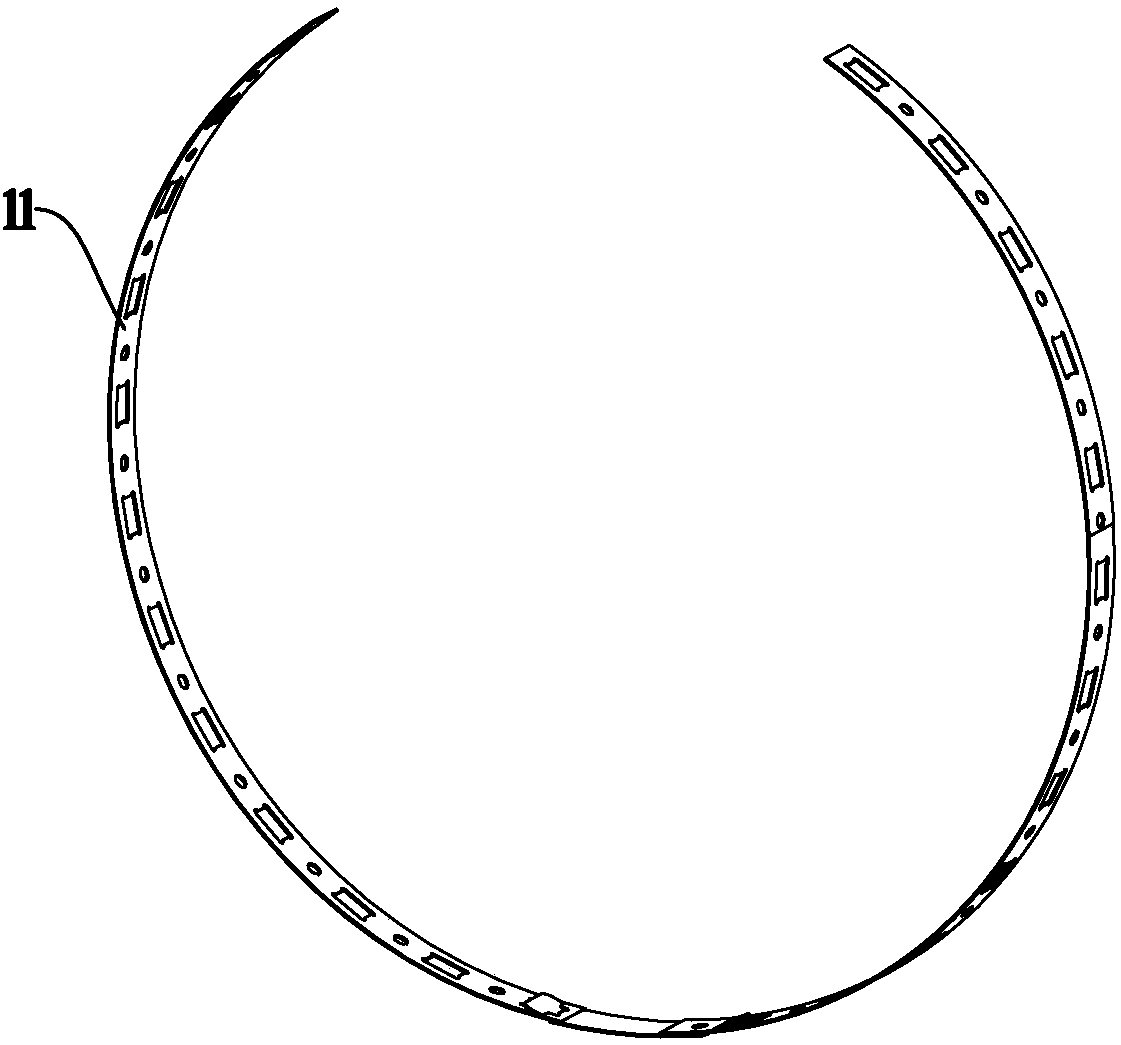

[0023] Such as Figures 1 to 7 A throat clamp with adjustable band length is shown, which includes a band 1 and a worm adjustment part 2. The band 1 includes a first connecting section 12, a band body 11 and a second connecting section 13. The band On the belt body 11, connecting holes 115 are arranged at equal intervals along the extending direction of the band 1. The worm adjustment part 2 is composed of a base 23, a worm 22 and an upper cover 21. The worm 22 is arranged on the base 23. The upper cover 21 covers the worm 22 and is fixedly connected with the base 23. One end of the second connecting section 13 is provided with a fixing part 131, and the fixing part 131 is fixedly connected with the worm ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com