Shooting box for shooting jewelry

A jewelry and box technology, applied in the field of shooting boxes, can solve the problems of high equipment cost, high cost of high-definition pictures, unreal images, etc., and achieve the effect of reducing shooting cost, improving shooting effect and shooting efficiency, and reducing shooting difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

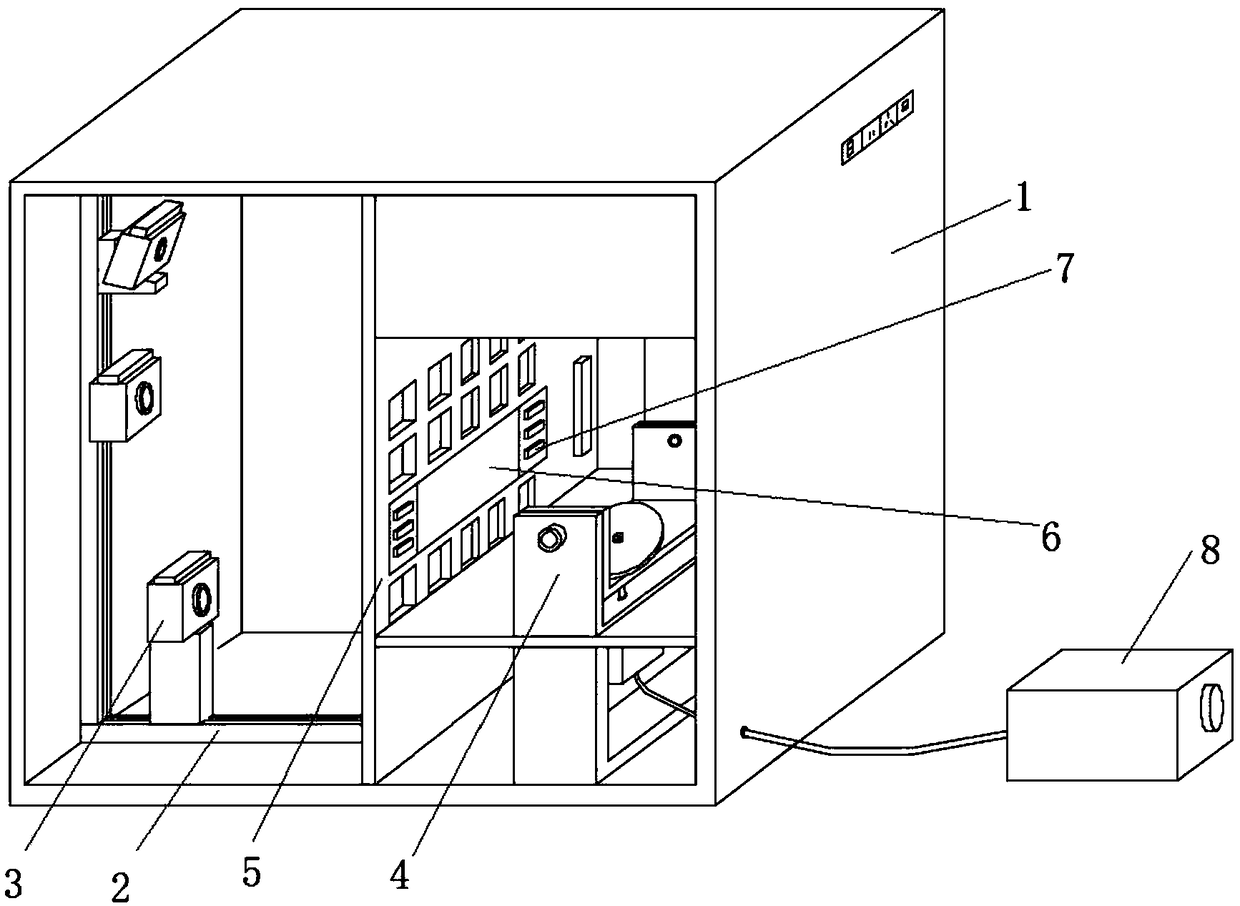

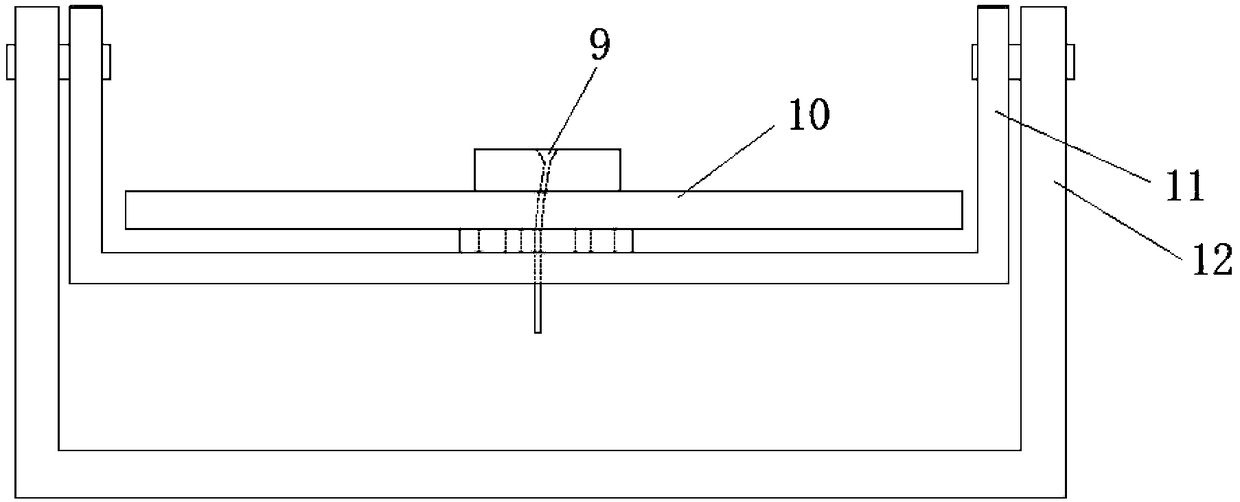

[0024] Such as figure 1 and figure 2 As shown, a shooting box for shooting jewelry includes a box body 1, at least one electric slide rail 2 and a rotatable base 4 are arranged in the box body, and a pedestal for placing jewelry is arranged on the base Groove 9; a camera 3 is installed on the electric slide rail, and the shooting direction of the camera is towards the base; one side and the top of the base are provided with LED7, and the four sides of the base are provided with mirrors for reflecting light. The invention reduces the environmental impact and improves the shooting effect by shooting inside the box; adjusting the position of the base and using a camera with multiple gears, the camera can be displaced through the electric slide rail, which is convenient for changing the position of the jewelry, shooting from different angles, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com