Coal yield monitoring method based on image analysis

An image analysis and coal technology, which is applied in the field of coal production monitoring devices, can solve the problems of the sensitivity of production monitoring effectiveness sensors and the inability of coal production monitoring methods to transmit monitoring data in real time, safely and effectively, and achieve the effect of improving automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

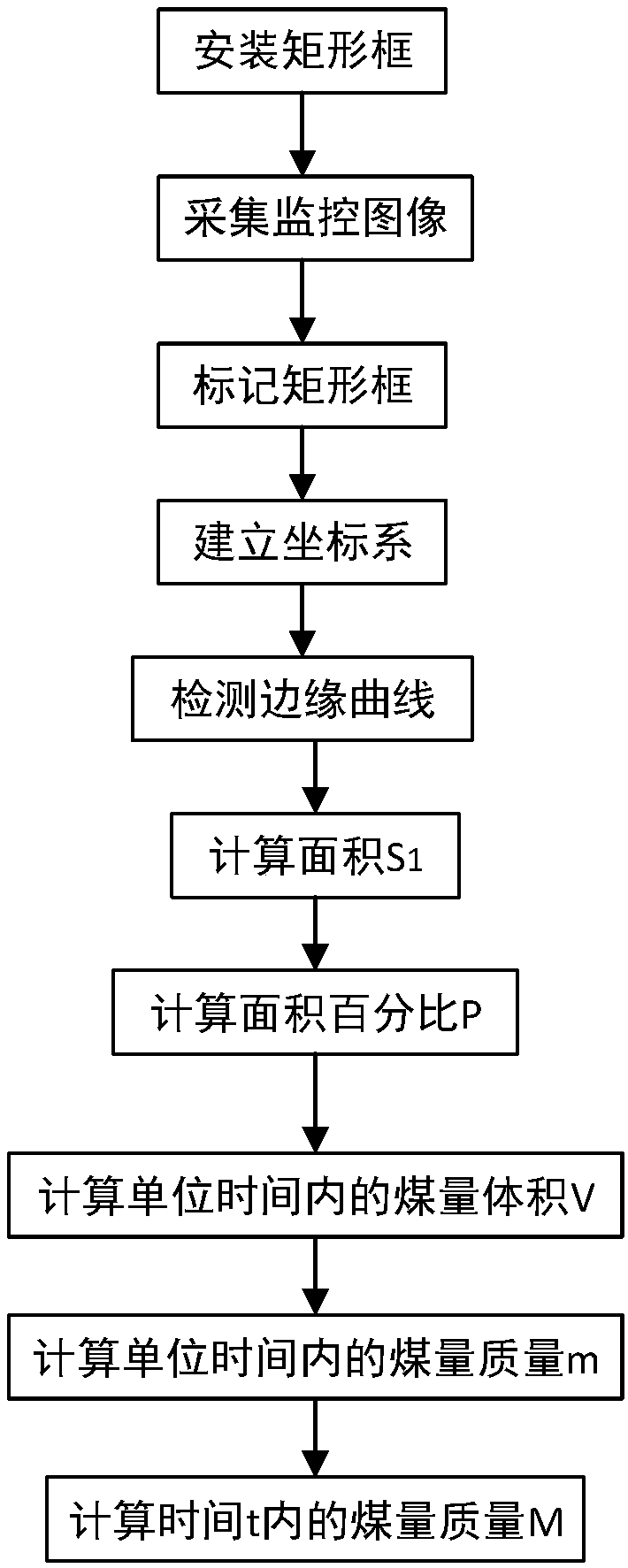

[0037] 1. A coal production monitoring method based on image analysis, characterized in that, such as figure 1 shown, including the following steps:

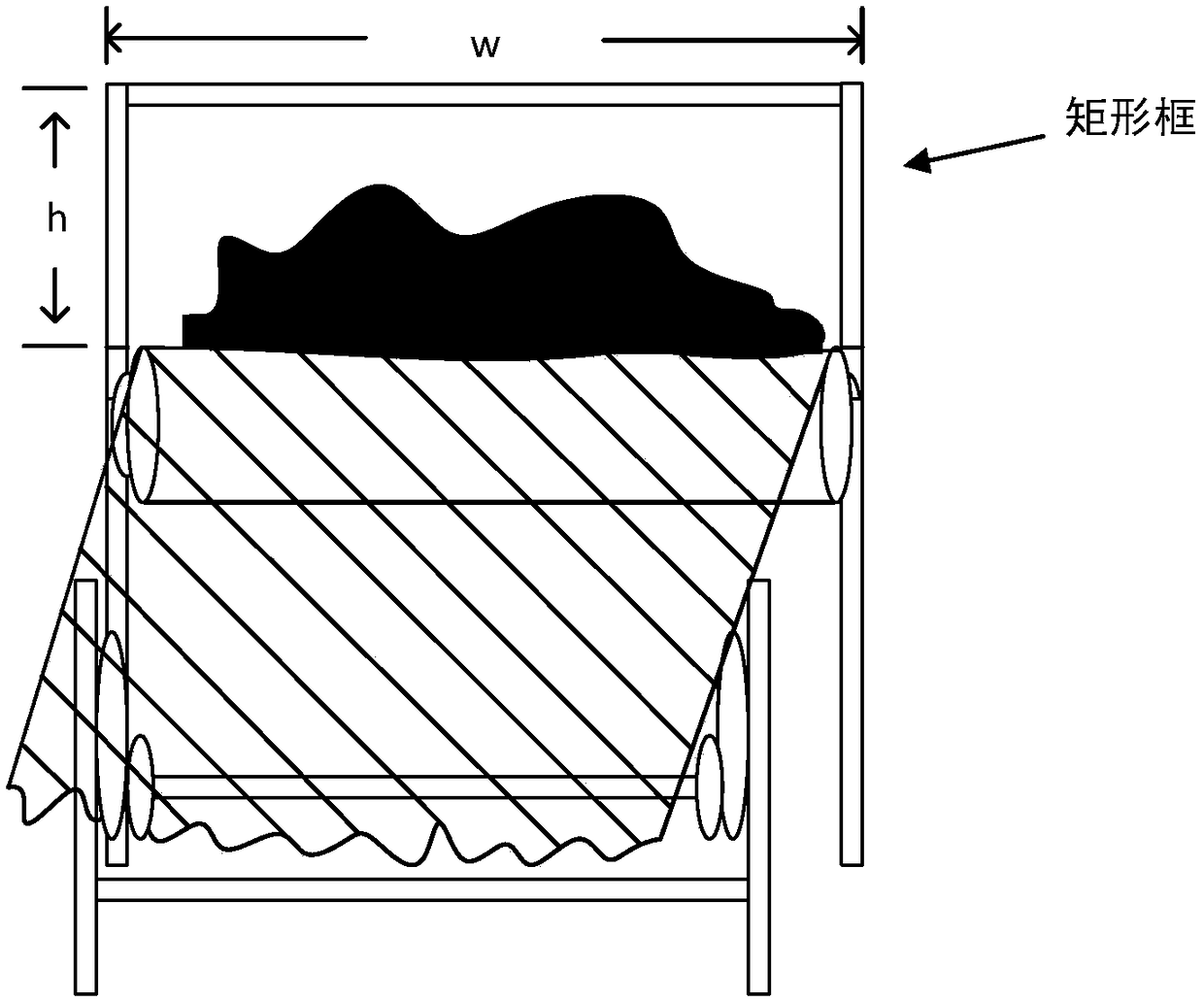

[0038] A: Install a rectangular frame with a width of w and a height of h at the head of the belt conveyor in the main shaft of the coal mine;

[0039] B: Collect the monitoring image at the head of the belt conveyor in the main shaft of the coal mine;

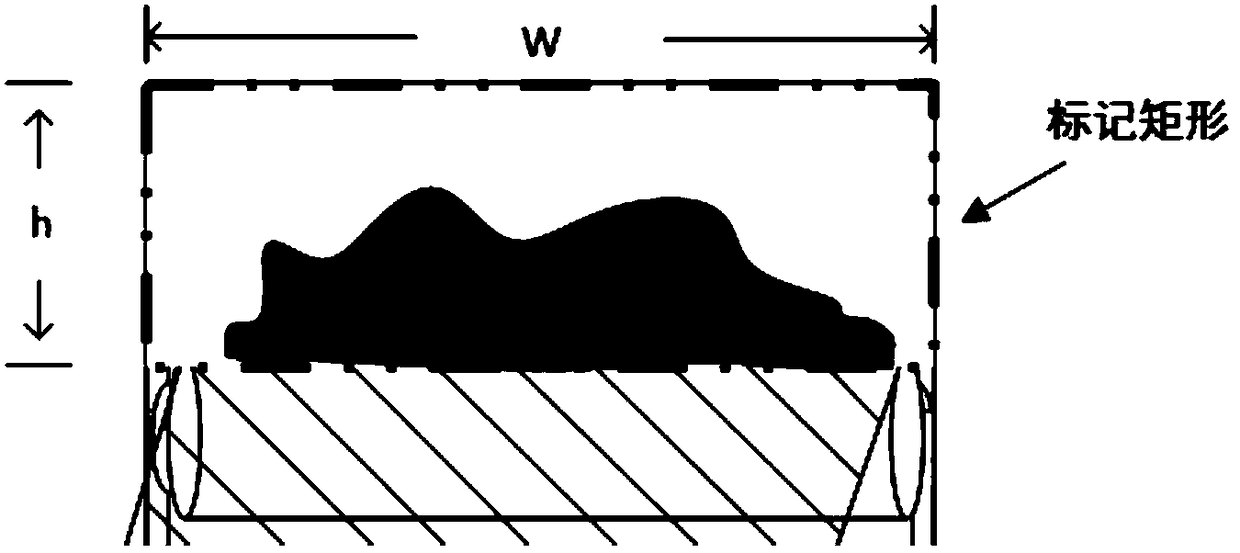

[0040] C: to described monitoring image, utilize the rectangle frame that rectangle mark step A place installs;

[0041] D: Establish the image pixel coordinate system with the lower left corner of the marked rectangle as the origin (0,0), and detect the coordinates of the other three corners of the marked rectangle, assuming that they are (m,0), (0,n) and ( m,n);

[0042] E: Utilize the edge detection algorithm to mark out the edge curve of the coal accumulation shape at the head belt place;

[0043] F: Calculate the area S surrounded by the horizontal coordinate axis of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com