Hydrate temperature control and heat dissipation low-voltage cable

A low-voltage cable, hydrate technology, applied in the direction of insulated cables, carbon-silicon compound conductors, cables, etc., can solve the problems of cooling liquid sealing and insulation problems, high cost of use, complex design, etc., and easy to eliminate. The effect of causing fire, low cost of use and maintenance, and fast heat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

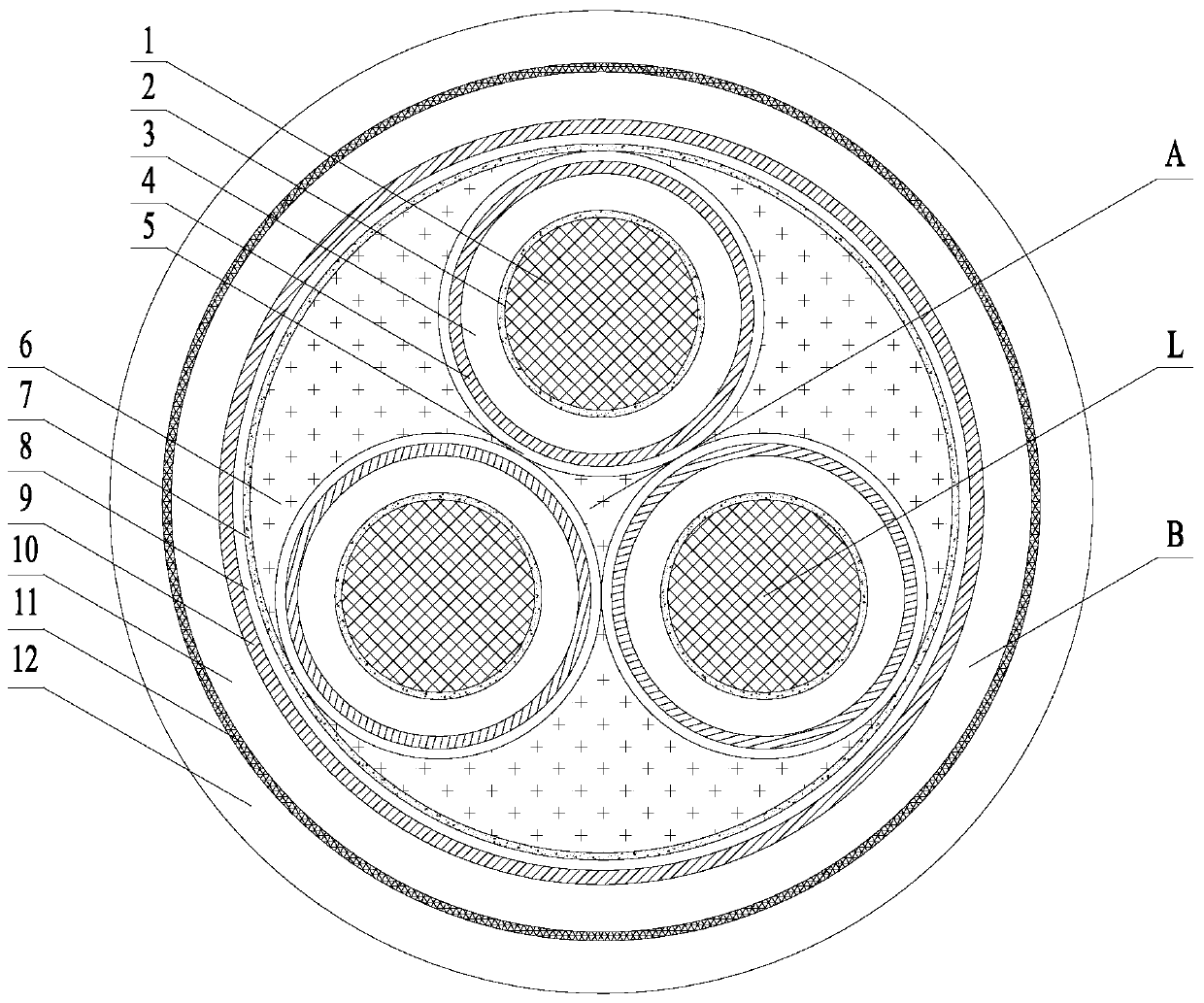

[0023] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0024] Such as figure 1 The shown low-voltage cable for hydrate temperature control and heat dissipation includes a central layer (A) and a sheath layer (B) wrapped around the outer periphery of the central layer (A).

[0025] The central layer (A) is formed by twisting three shielded insulated wires (L), and the hydrate material layer (6) is filled in the twisted gap of the three shielded insulated wires (L), and the shielded insulated wire ( L) Conductor (1), first nano-graphite coating (2), rubber insulating layer (3), inner shielding layer (4) and glass fiber protective layer (5) from inside to outside; the sheath Layer (B) from outside to inside is the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap