Monolithic integrated structure of bulk acoustic wave resonator and capacitor, manufacturing method thereof, filter, duplexer and radio frequency communication module

A bulk acoustic wave resonator, monolithic integration technology, applied in electrical components, impedance networks, etc., can solve the problems of bare chip and capacitor connection loss, reduced reliability of bulk acoustic wave filters, and large volume of bulk acoustic wave filters. Enhanced roll-off characteristics, avoid parasitic coupling effects, good roll-off characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

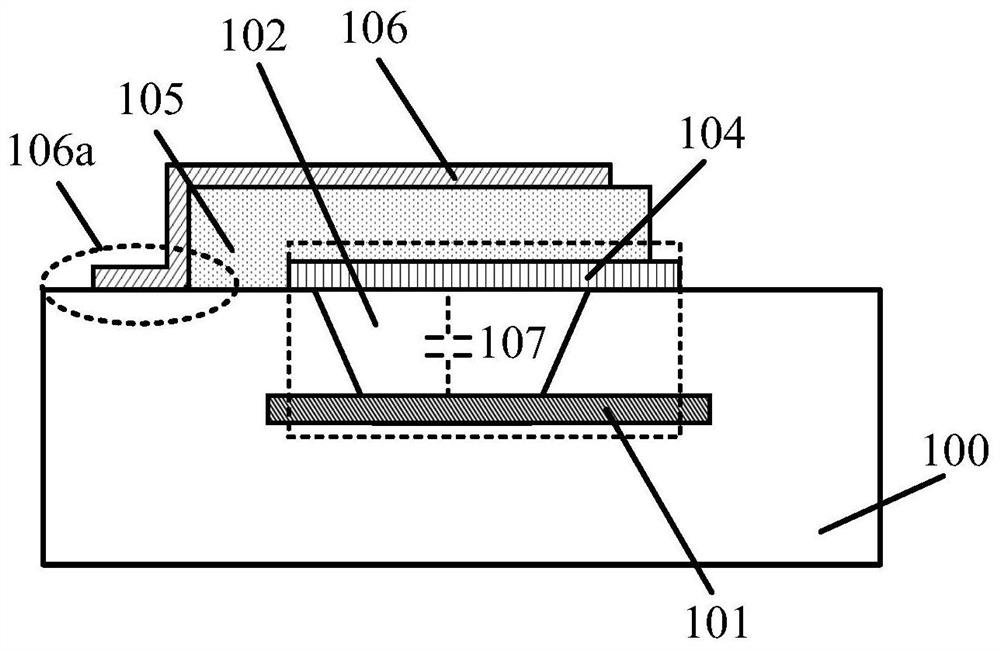

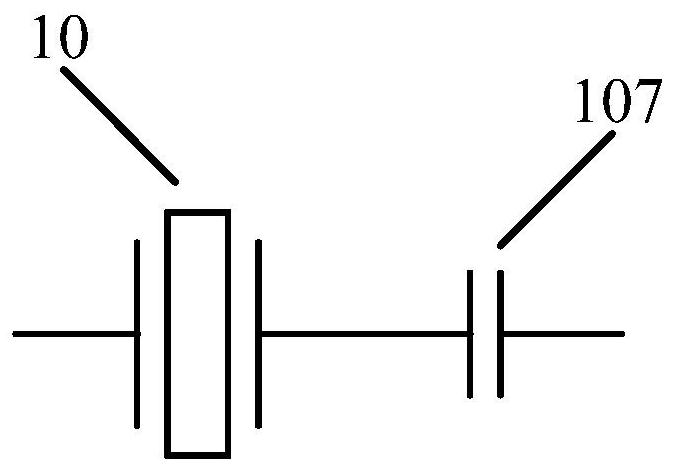

[0075] This embodiment provides a monolithic integrated structure of a bulk acoustic wave resonator and a capacitor, and the monolithic integrated structure of a bulk acoustic wave resonator and a capacitor includes:

[0076] Substrate;

[0077] a lower electrode, the lower electrode is disposed on the substrate and forms a cavity with the substrate;

[0078] a piezoelectric layer disposed on the lower electrode;

[0079] an upper electrode, the upper electrode is disposed on the piezoelectric layer;

[0080] A first electrode, the first electrode is disposed in the substrate below the cavity and has a first overlapping area with the lower electrode.

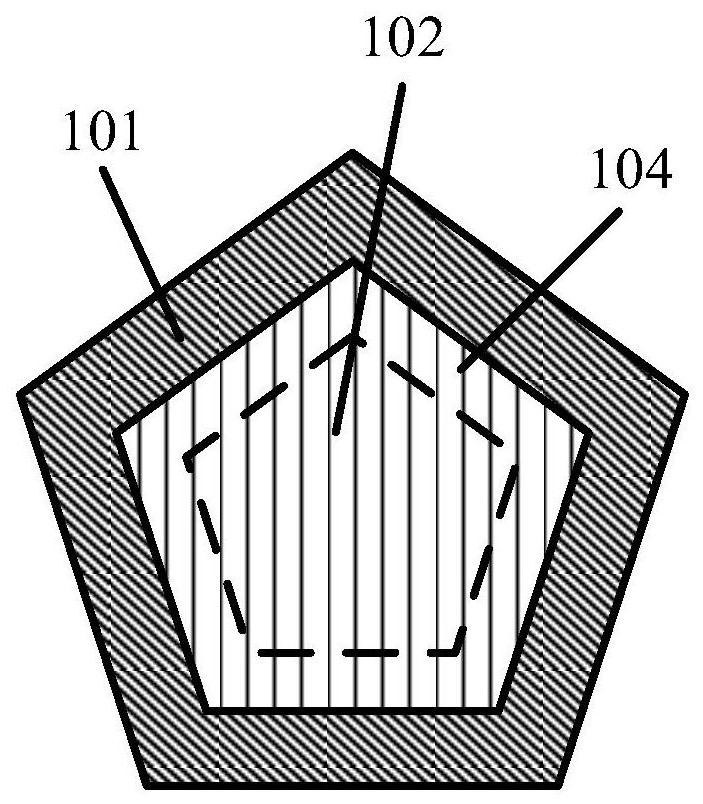

[0081] Next, various parts of the monolithic integrated structure of the bulk acoustic wave resonator and capacitor provided by this embodiment will be described in detail with reference to FIG. 1( a ).

[0082] Specifically, as shown in FIG. 1( a ), the monolithic integrated structure of a bulk acoustic wave resonator and a ...

no. 2 example

[0087] This embodiment provides a monolithic integrated structure of a bulk acoustic wave resonator and a capacitor. This embodiment is basically the same as the first embodiment, the difference between the two mainly lies in that the monolithic integrated structure of the bulk acoustic wave resonator and the capacitor in this embodiment also includes a second electrode arranged on the upper surface of the substrate, Wherein, in addition to forming an overlapping area with the lower electrode, the first electrode also forms an overlapping area with the second electrode.

[0088] Next, the monolithic integrated structure of the bulk acoustic wave resonator and capacitor provided by this embodiment will be described with reference to FIG. 2( a ). For the sake of brevity, only the difference between this embodiment and the first embodiment will be described in detail below, and for the same parts between this embodiment and the first embodiment, please refer to the content descri...

no. 3 example

[0093] This embodiment provides a monolithic integrated structure of a bulk acoustic wave resonator and a capacitor. This embodiment is basically the same as the first embodiment, except that the first electrode not only forms an overlapping area with the lower electrode, but also forms a gap between the upper electrode and the part extending to the upper surface of the substrate. form overlapping regions.

[0094] Next, the monolithic integrated structure of the bulk acoustic wave resonator and capacitor provided by this embodiment will be described with reference to FIG. 3( a ). For the sake of brevity, only the difference between this embodiment and the first embodiment will be described in detail below, and for the same parts between this embodiment and the first embodiment, please refer to the content description of the corresponding part in the first embodiment.

[0095] Referring to FIG. 3( a ), the upper electrode 106 extends from the piezoelectric layer 105 to the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com