Flywheel wood splitting machine

A wood splitter and flywheel technology, applied in the field of machinery, can solve the problems of short service life, slow working speed, oil leakage, etc., and achieve the effect of high safety performance and fast wood splitting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

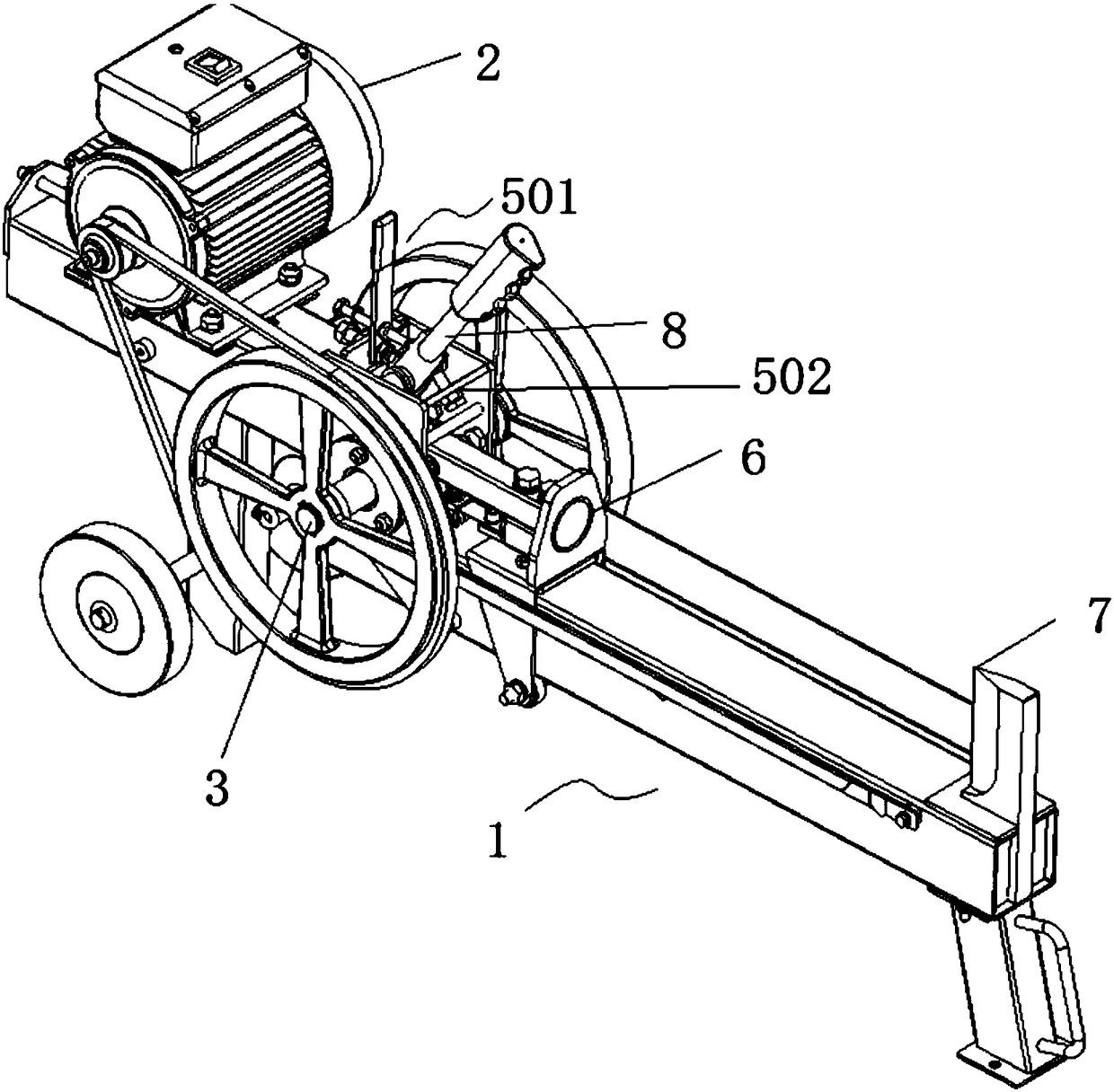

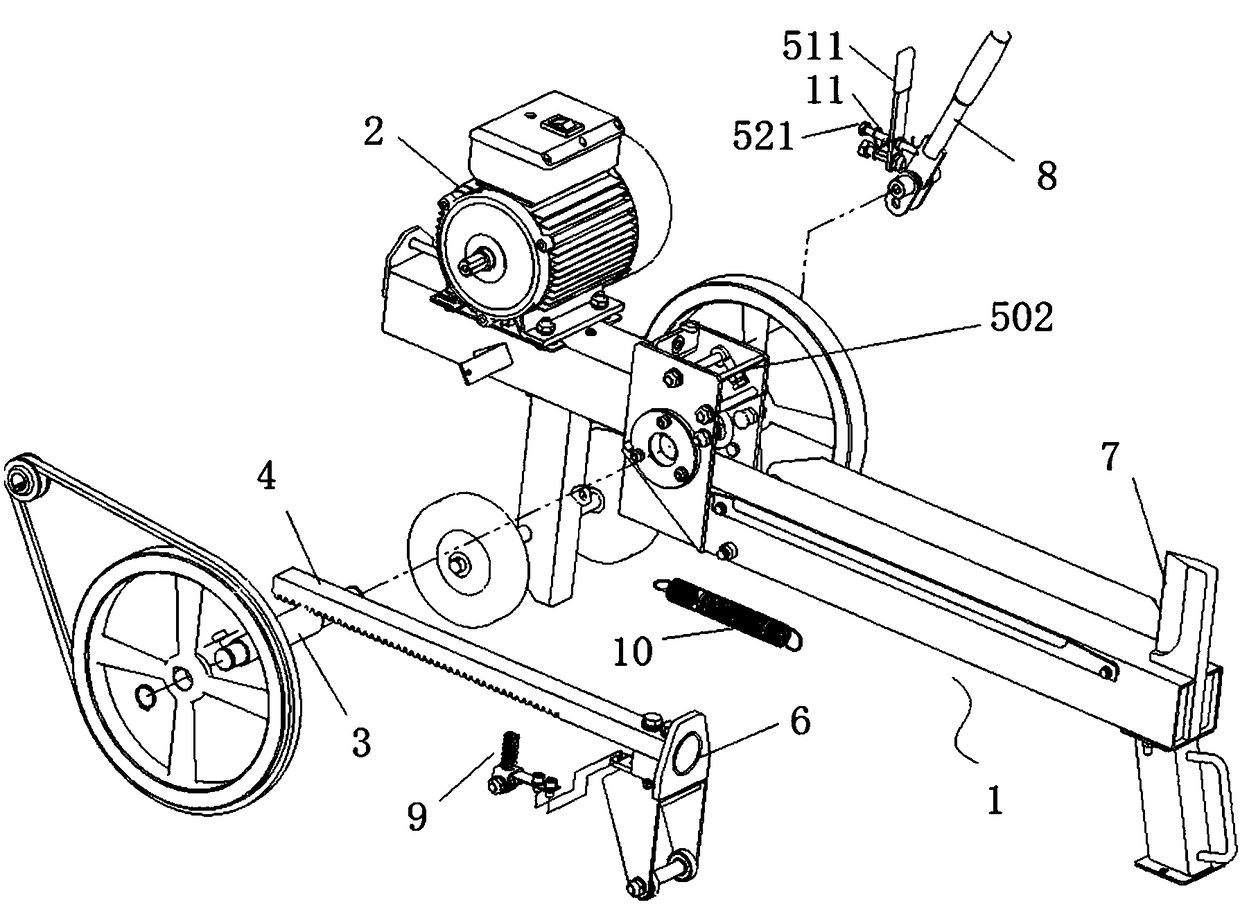

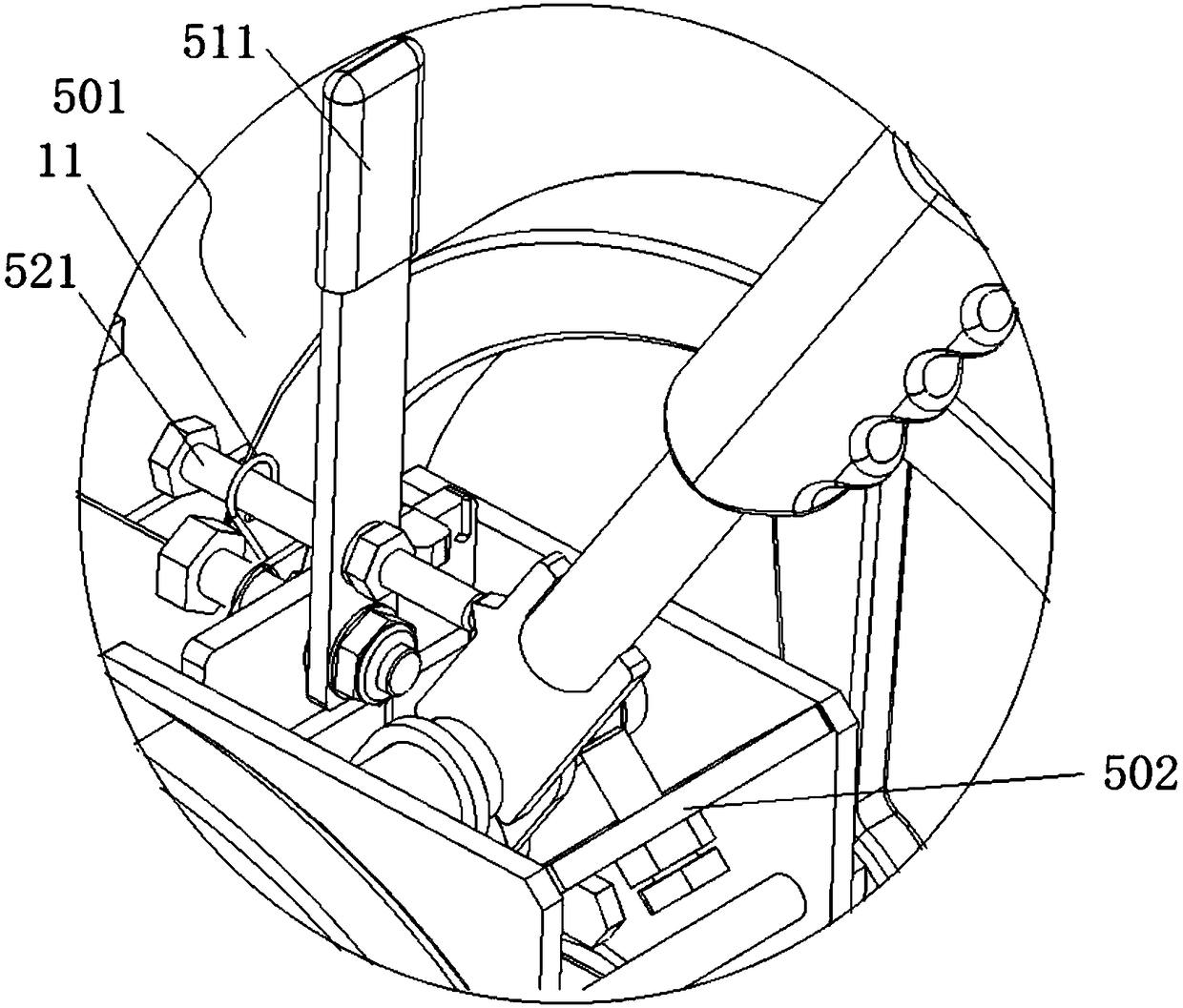

[0023] Such as figure 1 with figure 2 Flywheel wood splitters shown, including:

[0024] Frame 1 is a horizontal main rod, and the lower sides of the two ends of the main rod are provided with supporting frames, and rollers are installed on both sides of one supporting frame. The motor 2 is arranged at one end of the main pole.

[0025] Transmission main shaft 3, the transmission main shaft 3 is vertically mounted on the main pole and fixed by two fixed plates. The transmission main shaft 3 is set through the fixed plates. Increase the roller size on the transmission main shaft 3, realize the increase of the main shaft rotation force arm, thereby increase the wood splitting power.

[0026] Transmission rack 4, the transmission rack 4 is vertically intersected with the transmission main shaft, and is located above the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com