An in situ resource processing system utilizing electrostatic transport and concentrating fusion sintering

A resource processing and electrostatic technology, applied in the field of new in-situ resource processing systems, can solve the problems of in-situ resource transportation difficulties, low thermal conductivity, limited heat storage capacity, etc., and achieve simple and reliable composition, simple component composition, and overall high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand and understand the features, purposes and functions of the present invention, the design concept of the present invention will be described below in conjunction with specific embodiments, so as to understand the characteristics of the present invention, the detailed description is as follows:

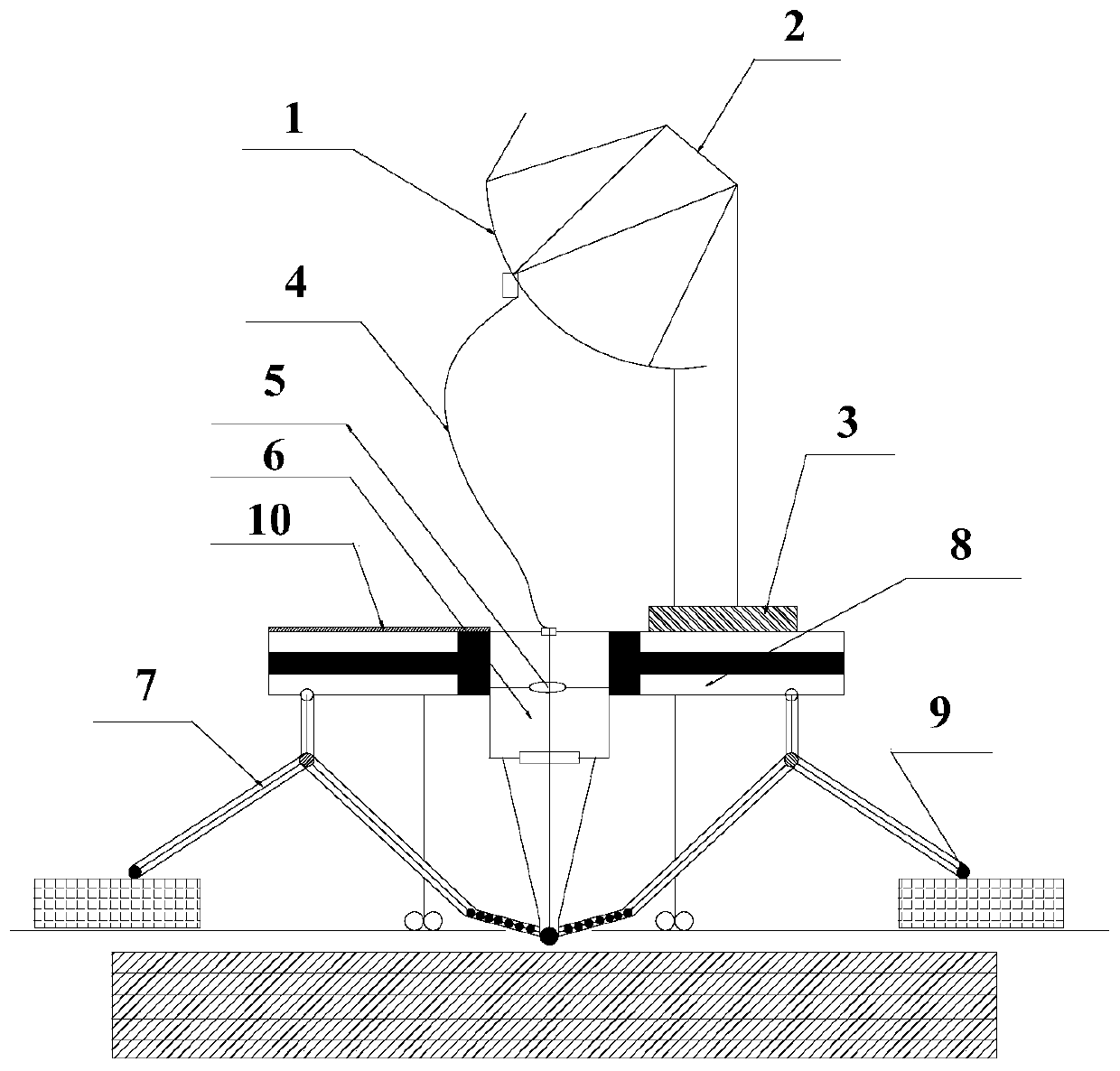

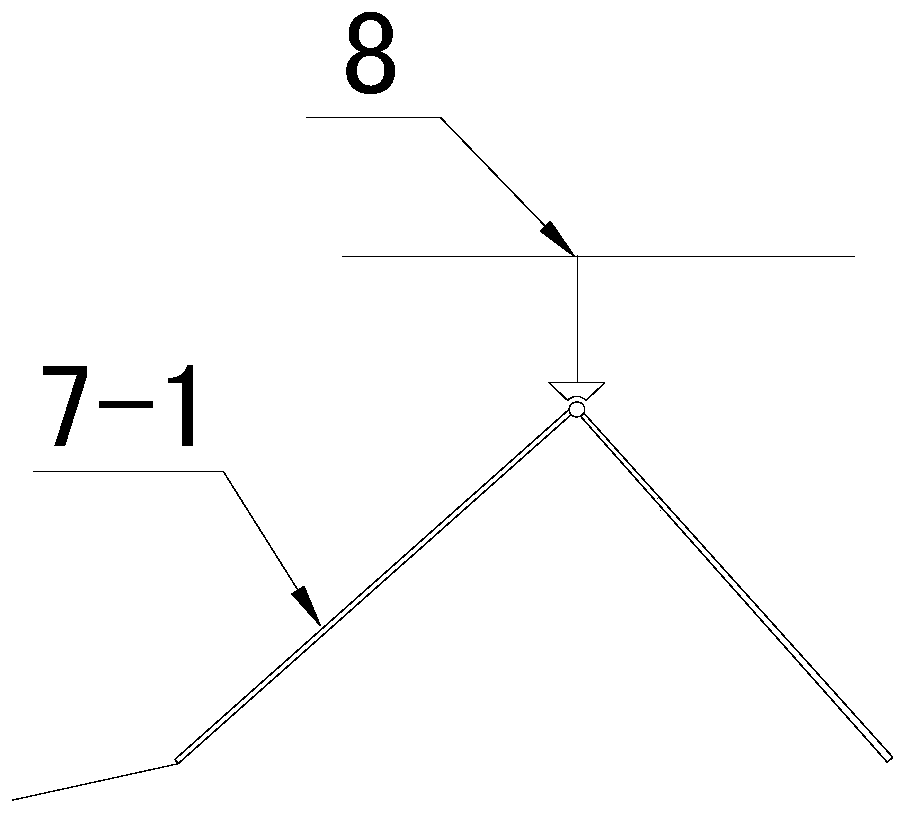

[0022] Such as figure 1 As shown in , 2, the in-situ resource processing system utilizing electrostatic transport and concentrating fusion sintering of the present invention mainly includes the electrostatic transport subsystem 7 and the concentrating fusion sintering subsystem.

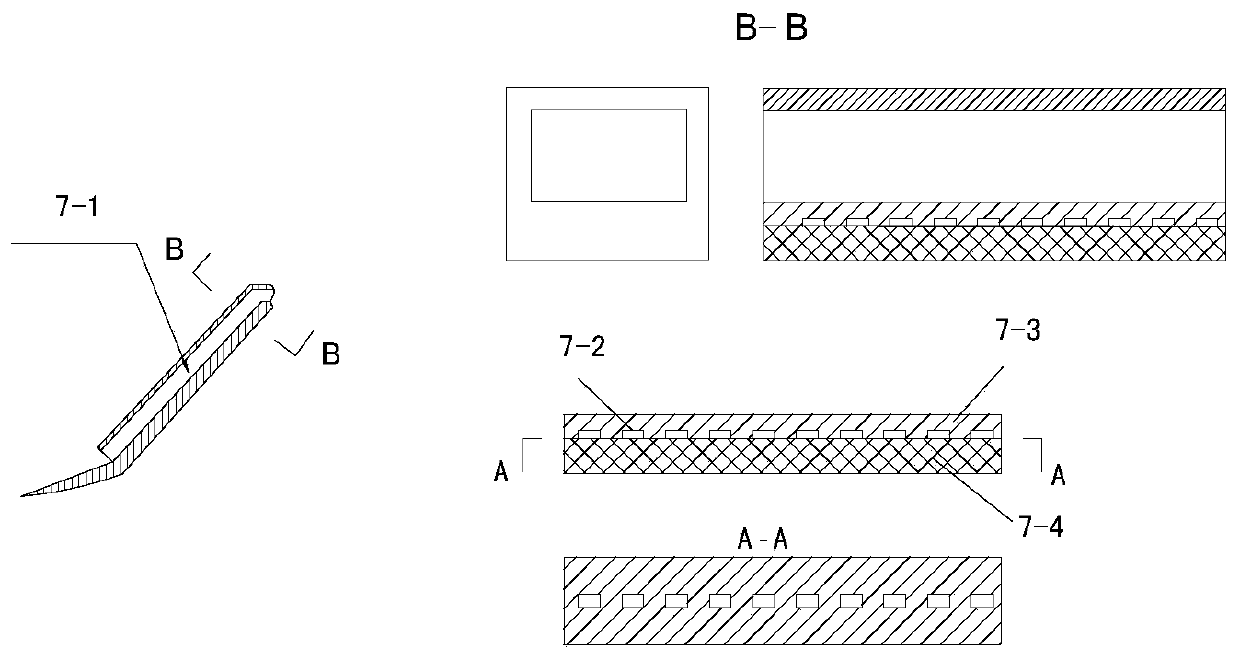

[0023] The electrostatic transport subsystem is mainly composed of an electric curtain, a power supply and a transport tube 7-1. Electric curtain is made up of electrode 7-2, insulating substrate 7-3 and insulating film 7-4, and electric curtain is generally divided into two kinds: opaque and transparent. Opaque generally uses polyester material as the insulating substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com