An automobile tensioner testing machine

A tensioning wheel and testing machine technology, which is applied in vehicle testing, machine/structural component testing, instruments, etc., can solve the problems of large inclination angle of the main shaft, failure of the shaft sleeve, failure, etc., to reduce the processing cost, Effect of improving efficiency and reducing design cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

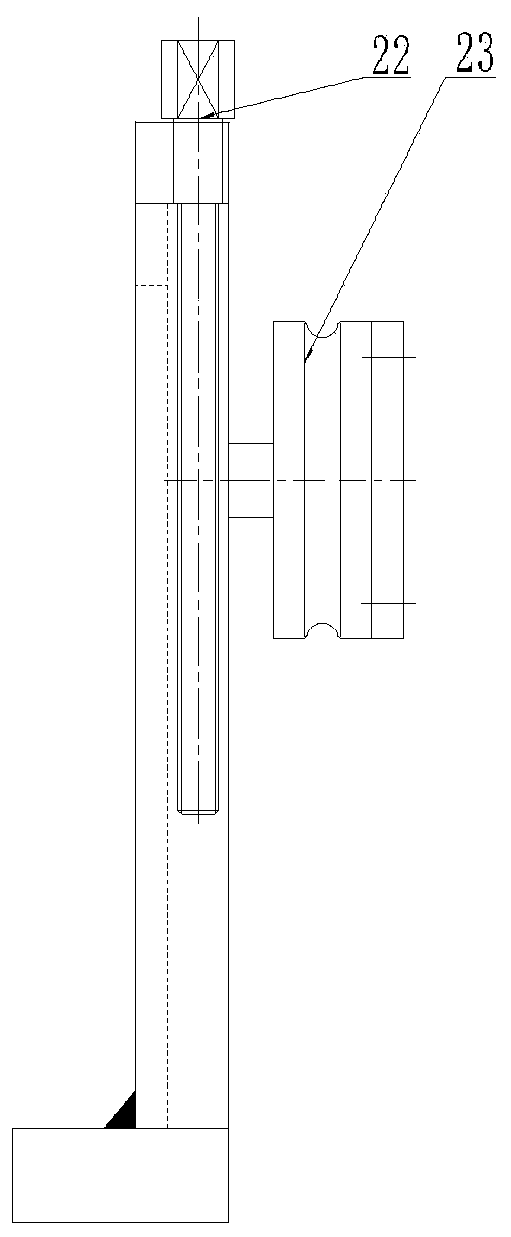

[0029] The tensioner 17 plays a decisive role in the stability of the steam transmission, and it is very easy to be damaged. After continuous testing and research, the main reason is that the inner shaft sleeve 14 and the tensioner main shaft 15 wear each other during work, causing the main shaft to tilt The angle becomes large and fails, and the high temperature generated during work is also a great test to the performance of the shaft sleeve 14. Therefore, the present invention is mainly tested against the tensioner spindle 15 .

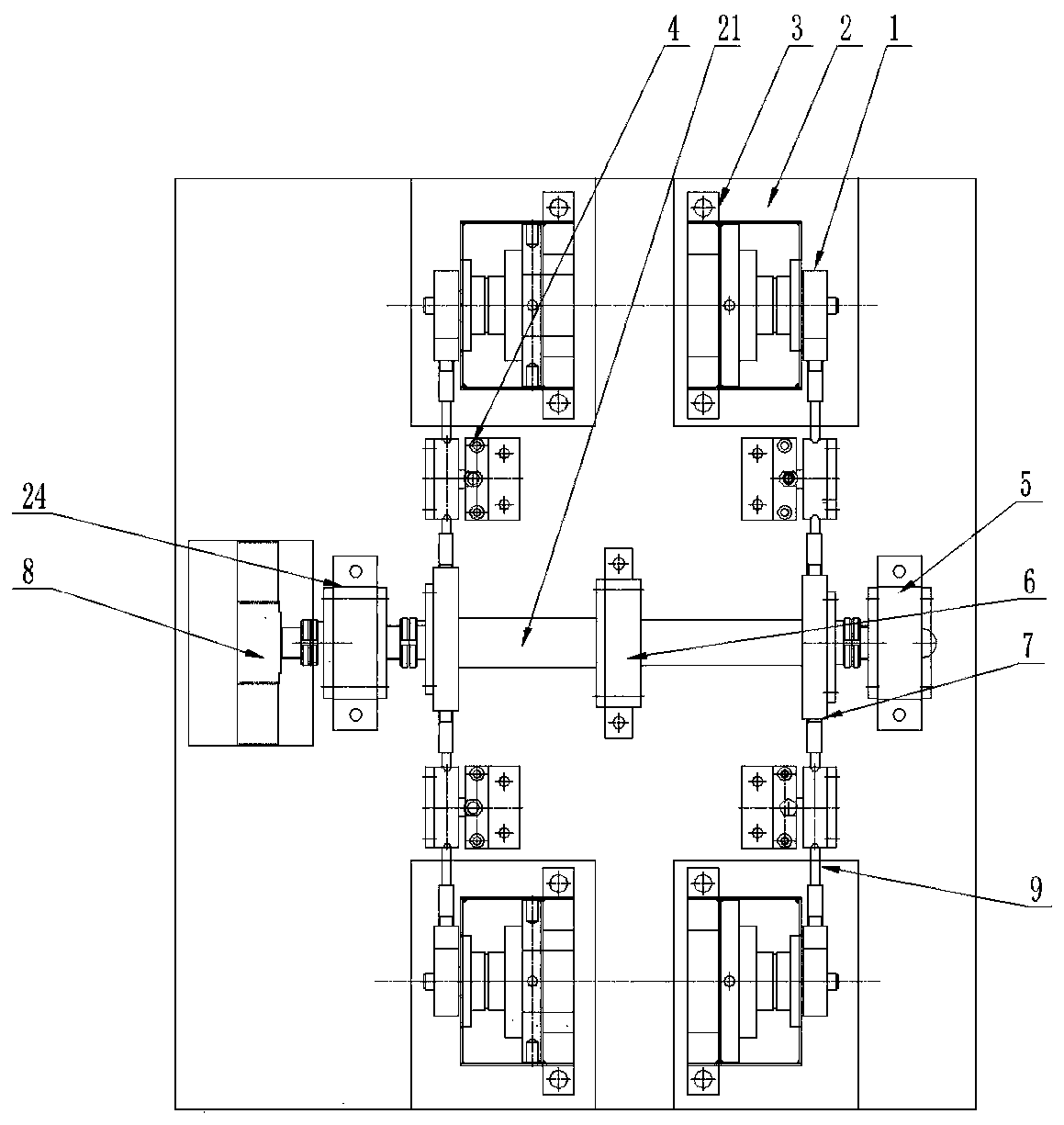

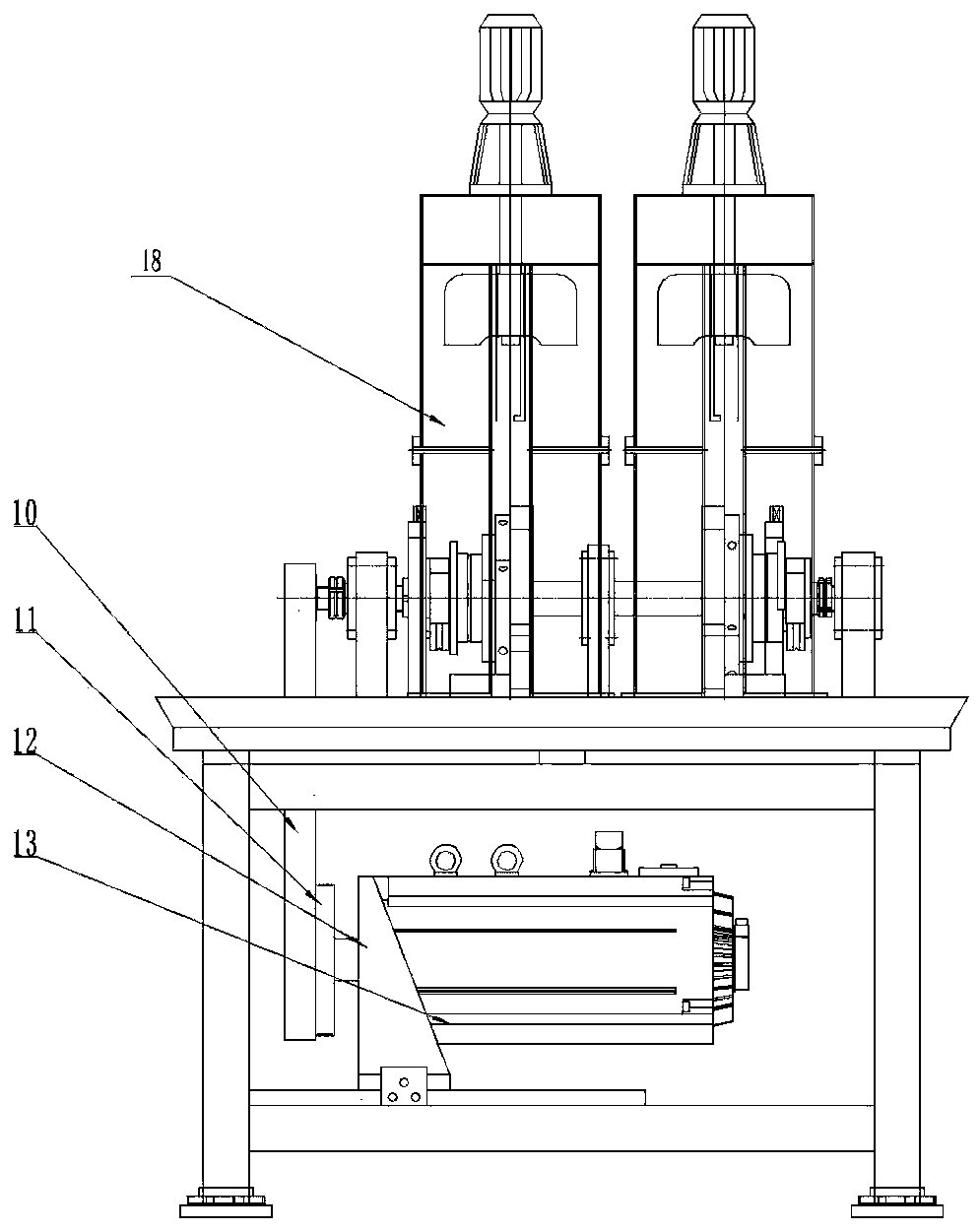

[0030] Such as figure 1 and figure 2 As shown, in the automobile tensioner testing machine of the present invention, the axle sleeve 14 is installed in the tensioner 17, and the present invention includes a drive unit, an eccentric swing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com