Electronic Discharge Machine

A technology of electric discharge machine and machining fluid, which is applied in the direction of electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high cost and complicated device structure, and achieve the effect of simple structure and cheap ion replacement ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

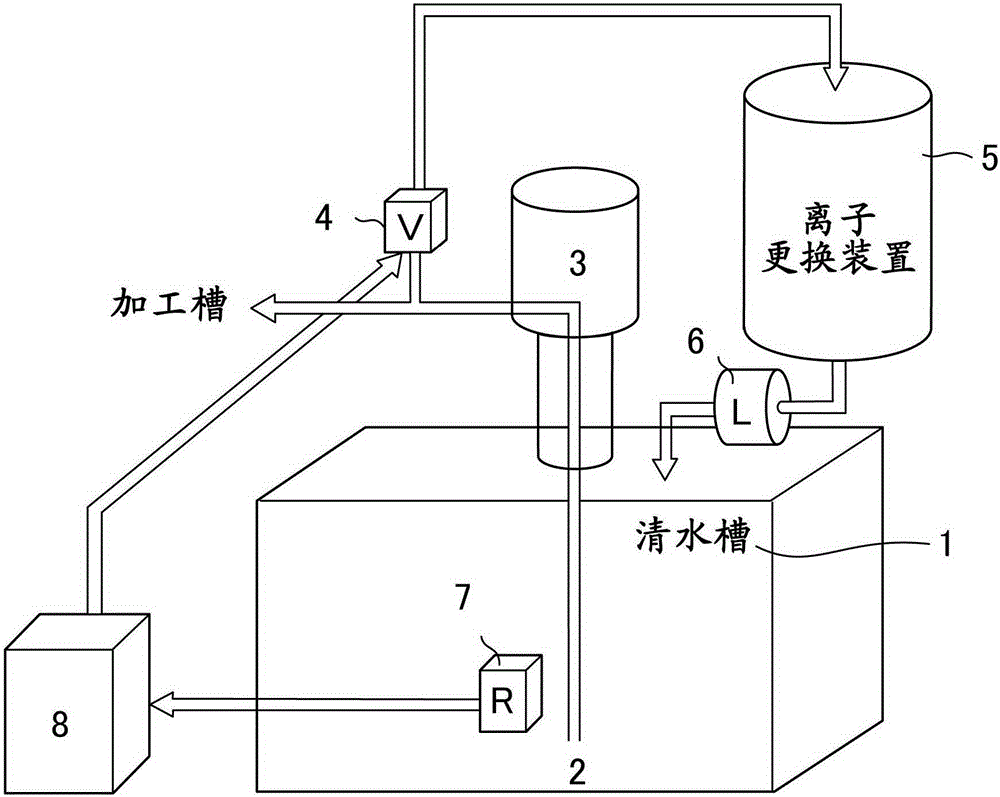

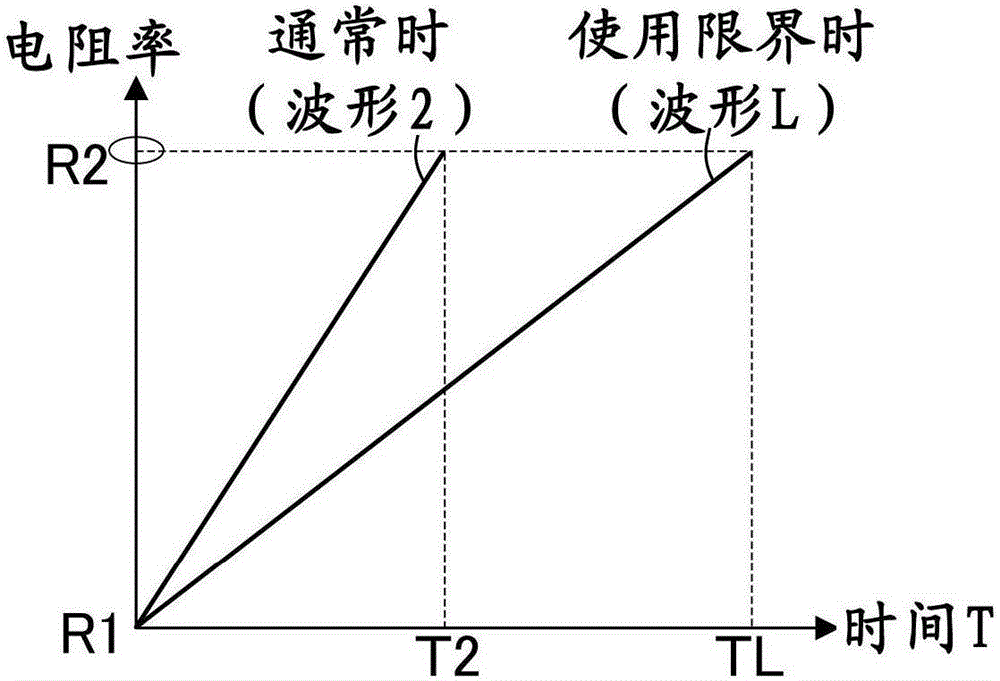

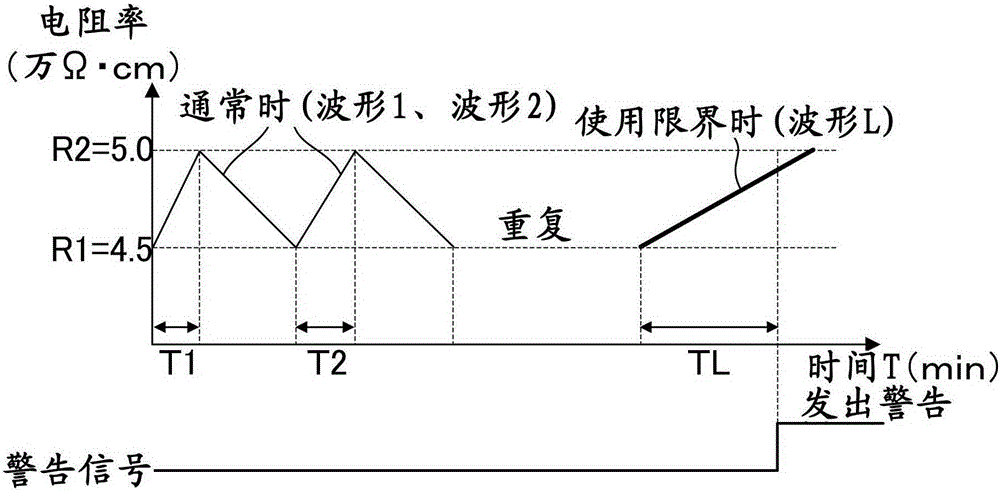

[0020] The basic structure and figure 1 The conventional electric discharge machine shown has the same structure. In this embodiment, during the period when the machining fluid 2 passes through the ion exchange device 5, the resistivity of the machining fluid 2 in the clean water tank 1 is detected by the resistivity detector 7, and the average slope of the resistivity value is recorded. If the average slope is low If it is less than a predetermined value, it is determined that the replacement time of the ion exchange device 5 has come, and a warning is issued to the operator.

[0021] exist figure 1 In the process, the working fluid 2 stored in the clean water tank 1 is pumped by the pump 3 and supplied to the processing tank. At this time, when the resistivity value of the machining fluid 2 detected by the resistivity detector 7 is lower than a predetermined allowable range, the control device 8 controls the switching valve 4, thereby supplying the machining fluid 2 to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com