High-sensitivity resistance-type flexible tensile strain sensor based on ball valve shape

A high-sensitivity, tensile-strain technology, applied in the field of high-sensitivity resistive flexible tensile-strain sensors, can solve the problems of applications that cannot meet a large range, decreased sensitivity, etc., to improve the sensitivity and measurement range, and increase the stretchable length. , the effect of a large measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

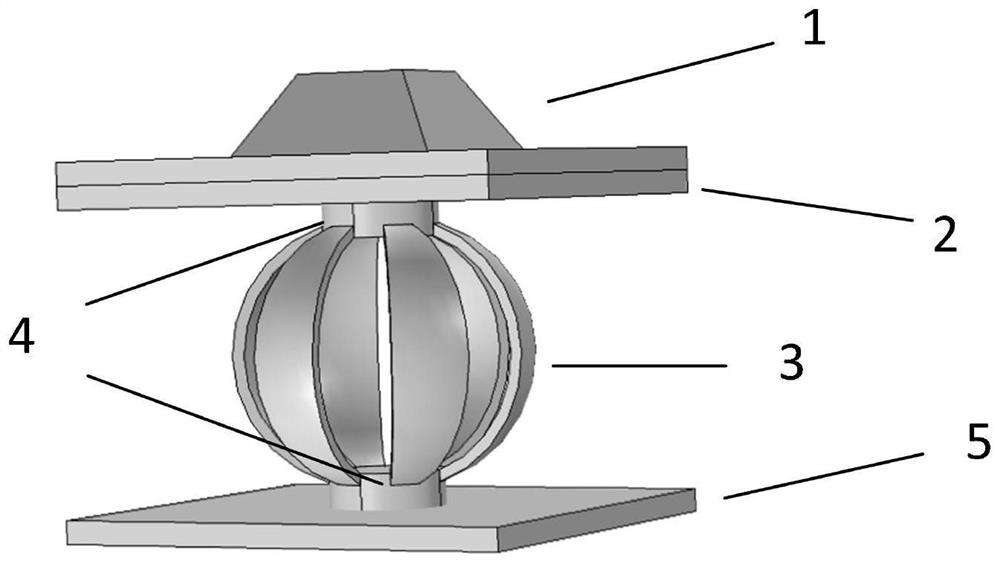

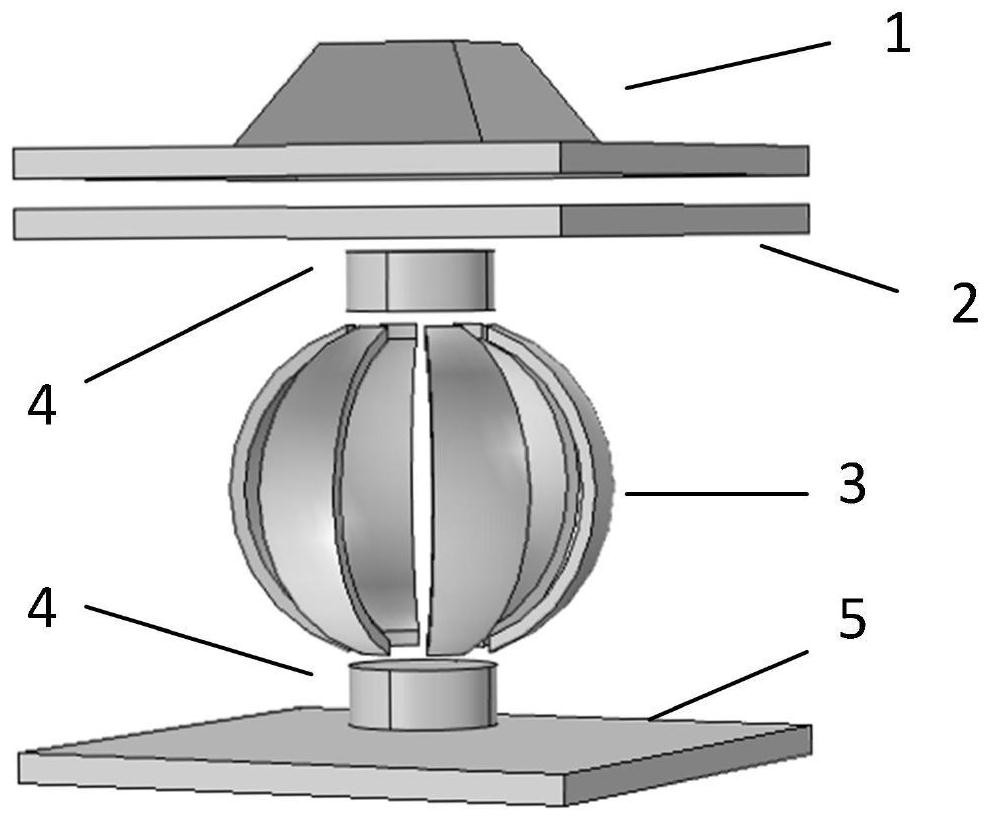

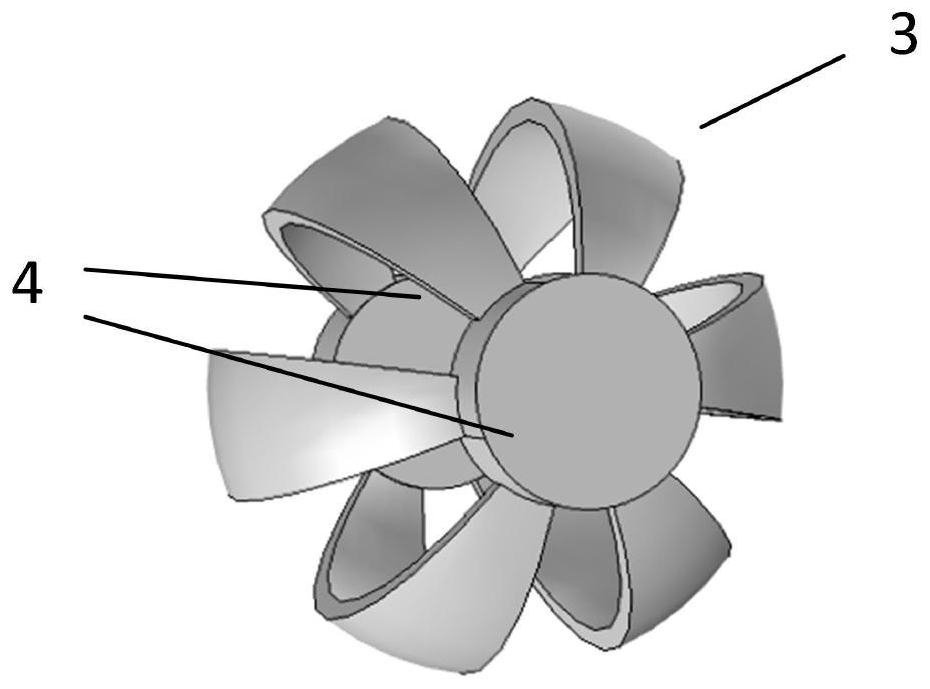

[0039] Such as figure 1 , figure 2 As shown, a high-sensitivity resistive flexible tensile strain sensor based on a spherical petal shape in this embodiment includes a PDMS stress loading layer 1, an upper electrode layer 2, a carbon black / silicone rubber flexible force-sensitive film layer 3, and 2 Carbon black / silicone rubber cylindrical base 4 and lower electrode layer 5. Among them: the PDMS stress loading layer 1 is formed by bonding a frustum-shaped structure and a cuboid structure of the same material, and the frustum-shaped structure is located in the center of the upper surface of the cuboid structure. The lower surface of the cuboid structure of the PDMS stress loading layer 1 is bonded to the upper electrode. The upper surface of layer 2; carbon black / silicone rubber flexible force-sensitive film layer 3 is a spherical structure surrounded by 6 spherical petals evenly spaced along the circumferential direction; the upper and lower ends of the 6 spherical petals ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com