Visual continuous tracking test method of freezing and thawing damage processes of cement materials

A testing method, technology of cement materials, applied in the direction of analyzing materials, using radiation for material analysis, using wave/particle radiation for material analysis, etc., can solve the problems of unreliable evaluation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

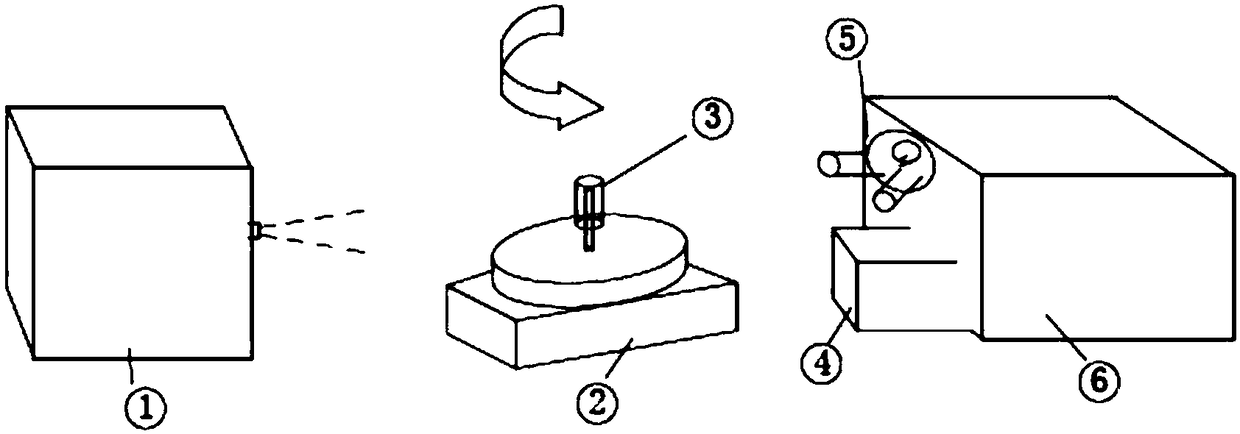

Method used

Image

Examples

Embodiment 1

[0046] Use ordinary Portland cement of PO 42.5(R) specification (manufacturer: Yingde Conch Co., Ltd.), and use standard sand produced in accordance with the national standard GB / T17671-1999 (manufacturer: Xiamen Aisiou Standard Sand Co., Ltd.) With ordinary water, configure cement mortar according to the ratio W:C:S=1:2:6; use a cube mold with a length of 8mm, a width of 8mm, and a height of 8mm, and then introduce the cement mortar into the mold, and smear the surface of the sample Flat, form a flat surface, vibrate, compact, and shape; remove the mold after 24h, and then place it in a standard curing room (relative humidity 95±5%, temperature 20±2℃) for 24 days of curing, then take it out The sample is immersed in water at a temperature of 20℃±2℃ for 4 days, and it can be used as a cement mortar sample for freeze-thaw cycle testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com