Automatic derusting and painting device for inner wall of steel tube

A technology for the inner wall of a steel pipe and a rotating drive device, which is applied in the direction of spraying devices, used abrasive processing devices, abrasive jetting machine tools, etc., can solve the problems of narrow and long inner wall space, affecting product quality, rust removal, etc., to ensure product quality, The effect of solving inner wall corrosion and improving surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

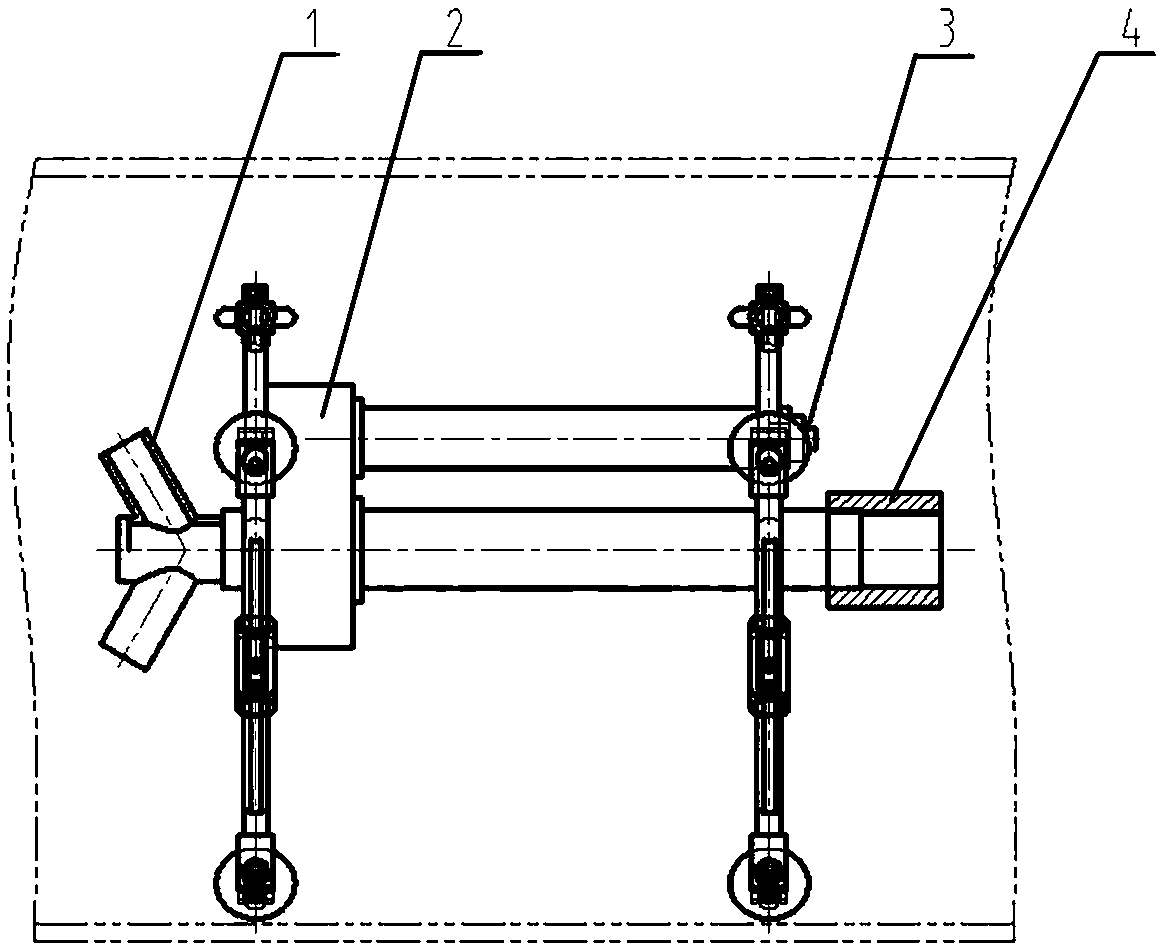

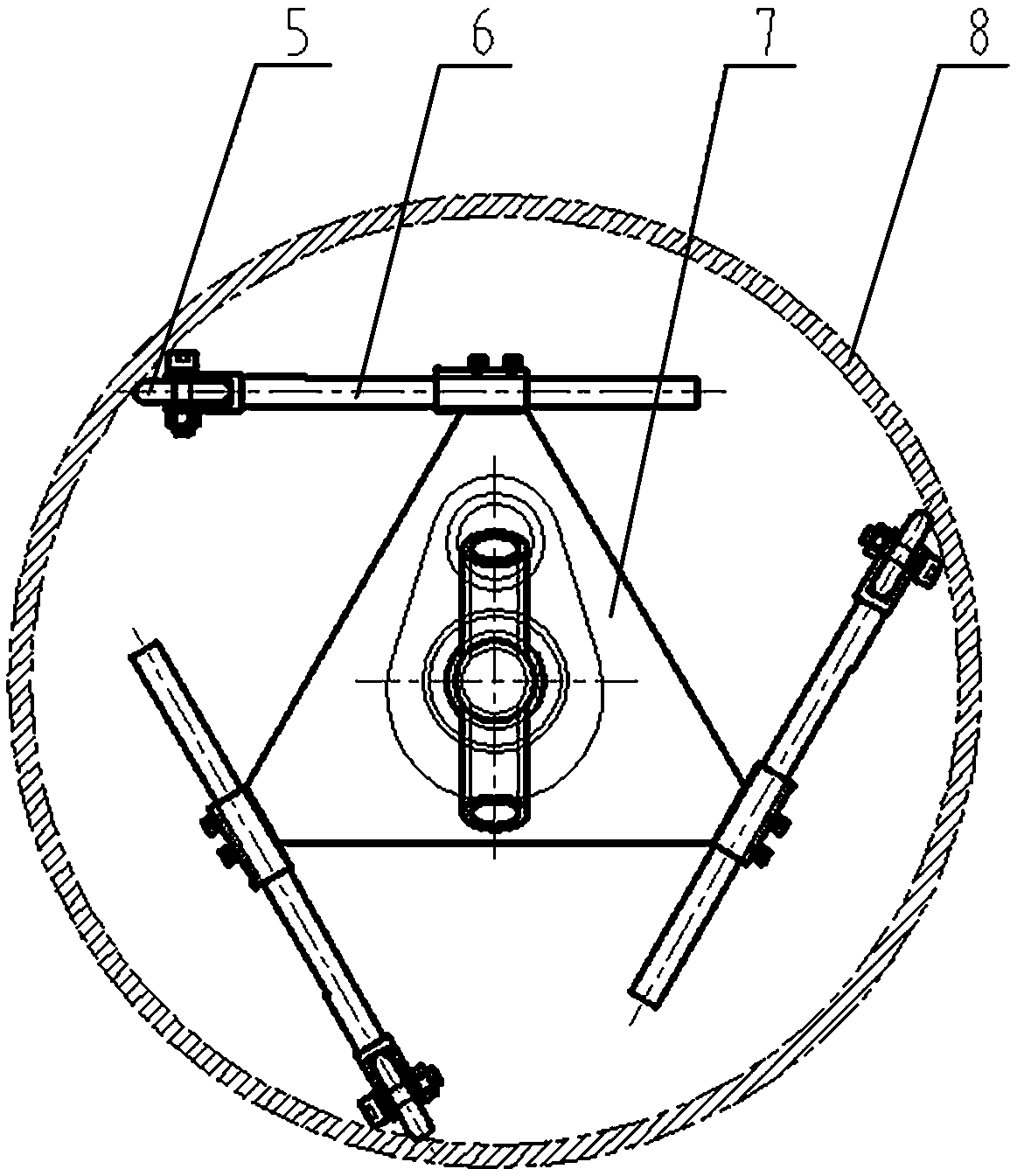

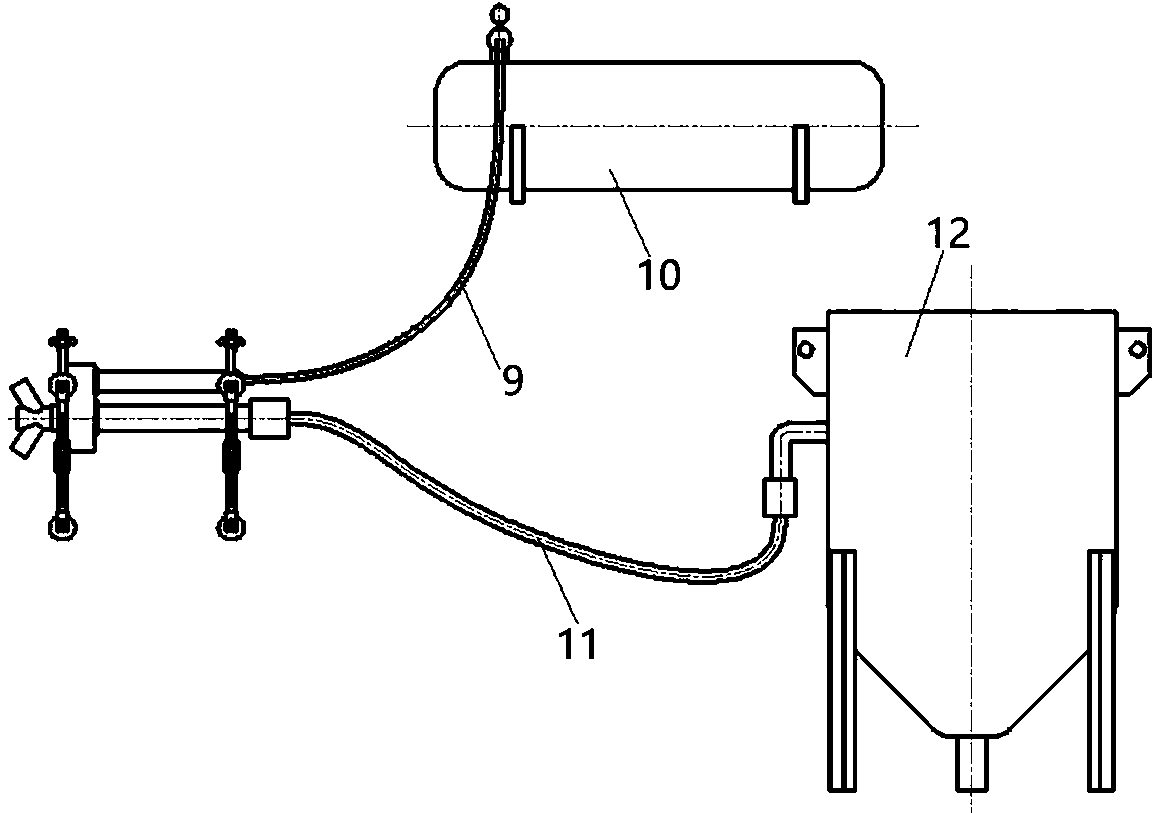

[0023] as attached Figure 1-4 As shown, an automatic derusting and painting device for the inner wall of a steel pipe has two brackets 7, and an air source pipeline and a consumable material pipeline are arranged between the two brackets 7. The gas source pipeline is connected to the rotary drive device 2, and the rotation The driving device 2 provides rotational power for the rotary nozzle 1, the consumable pipeline is connected to the rotary nozzle 1, one end of the air source pipeline has an air source interface 3, one end of the consumable pipeline has a consumable pipeline interface, and the outer edge of the bracket is provided with a guide wheel 5 , wherein the nozzle of the rotary nozzle 1 points to the inner wall of the steel pipe 8 .

[0024] The rotary driving device 2 adopts an air motor.

[0025] When carrying out the derusting operation, it is only necessary to connect the sandblasting pipe of the derusting machine to the consumable pipeline interface, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com