Packing device for large-scale packaging tape

A packer and tape technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as inability to use, large friction, and excessive tape, so as to facilitate reuse, increase the scope of use, and facilitate handheld use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

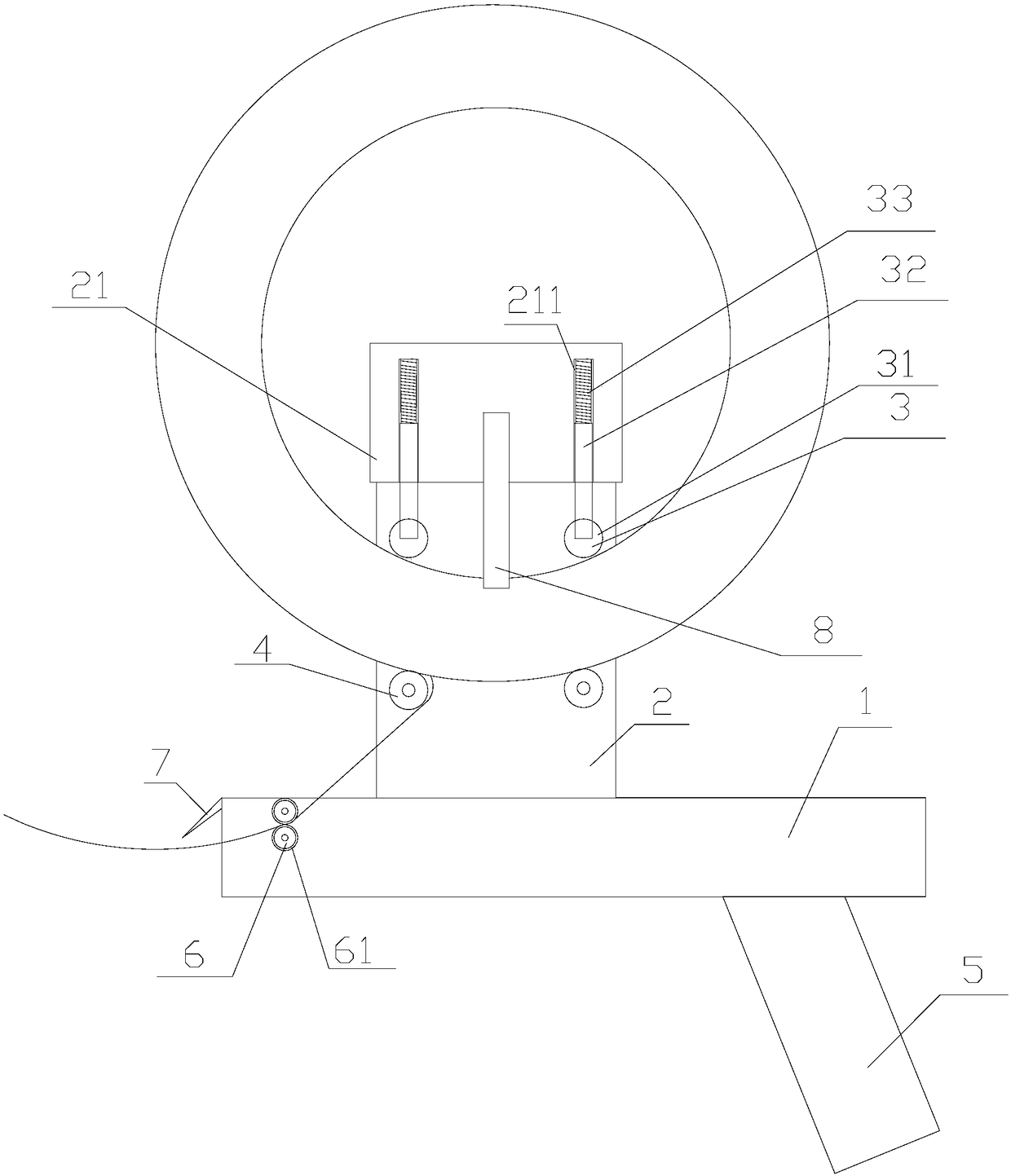

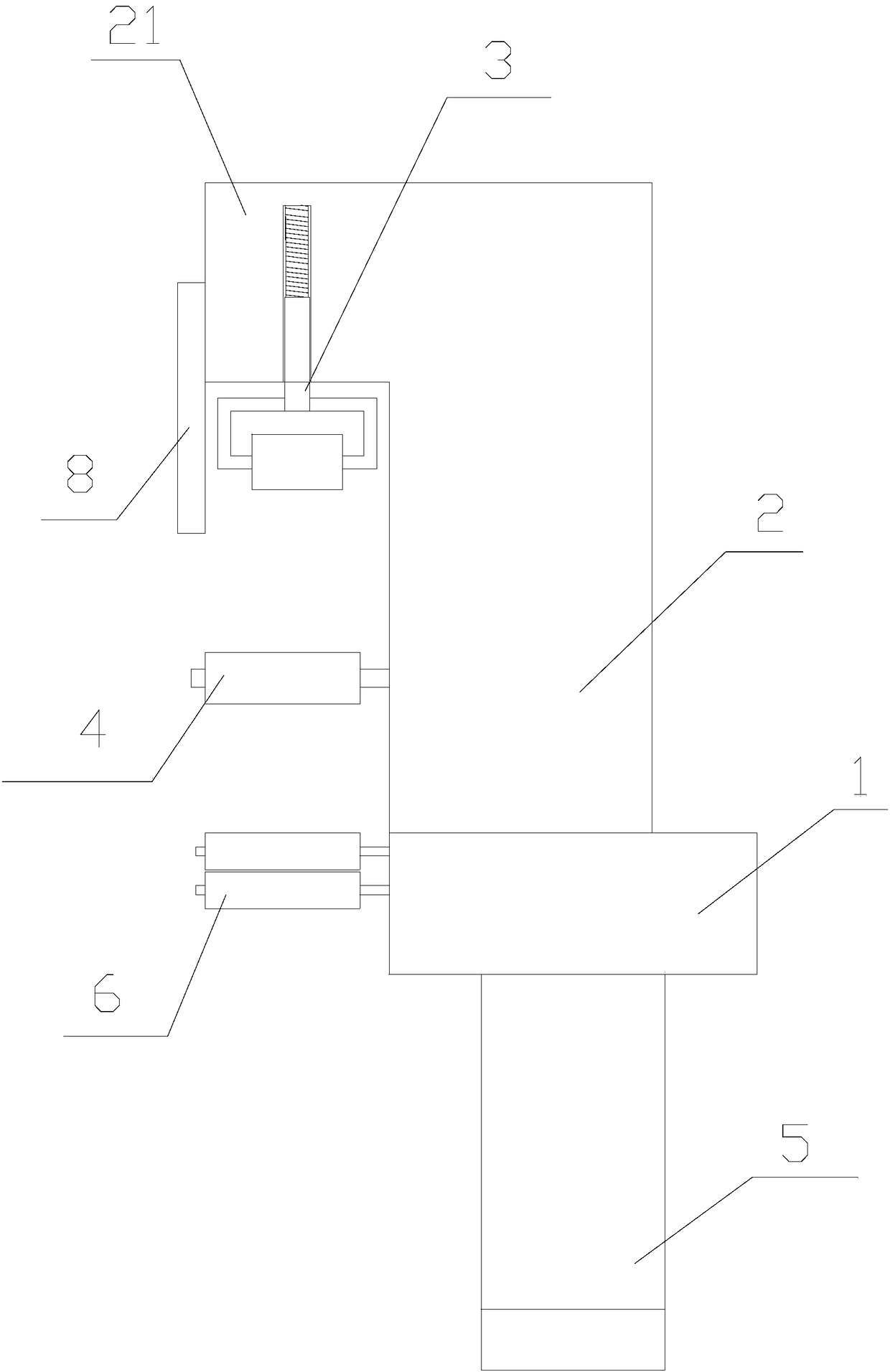

[0019] refer to figure 1 , figure 2 , a kind of packing device for large-scale adhesive tape of the present invention, comprises main body 1, upper support plate 2, pressing wheel device 3, roller shaft 4, grip 5, tape roller 6, described main body 1 is provided with upper support plate 2, The upper support plate 2 is provided with a plurality of roller shafts 4, the upper end of the upper support plate 2 is provided with a bump 21, and the bump 21 is provided with a plurality of pressure roller devices 3, and the lower end of the main body 1 is There is a handle 5, the front end of the main body 1 is provided with a tape roller 6, the pressure wheel device 3 includes a roller 31, a support rod 32 and a spring 33, and the protrusion 21 is provided with a mounting cavity 211. The installation cavity 211 is provided with a spring 33, the upper end of the spring 33 is connected with the top of the inner wall of the installation cavity 211, the lower end of the spring 33 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com