Self-locking bolt

A bolt and self-locking technology, applied in the direction of bolts, screws, nuts, etc., to achieve the effects of good practicability, cost reduction, and reduced assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

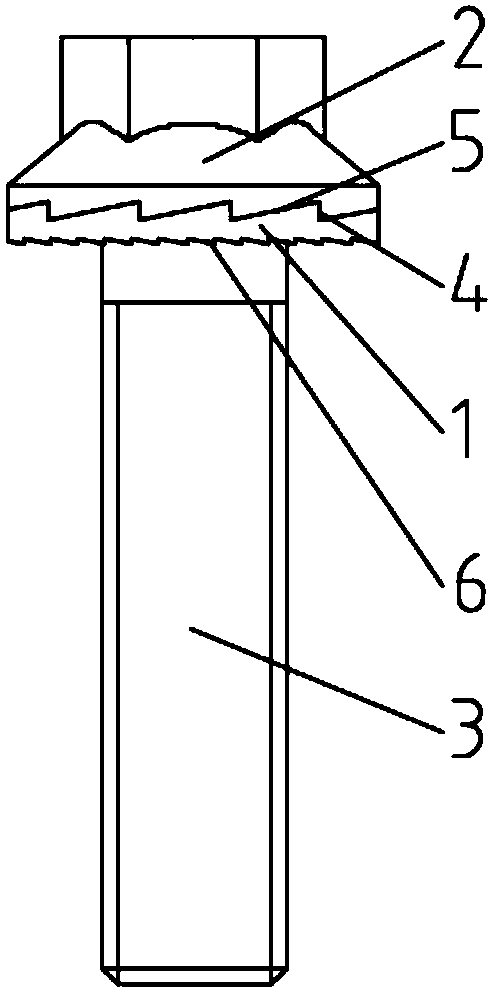

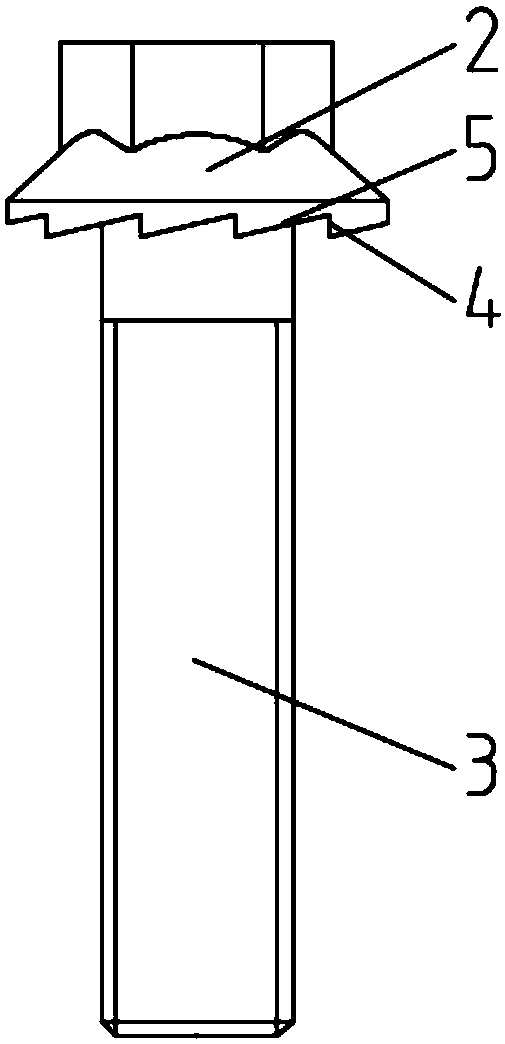

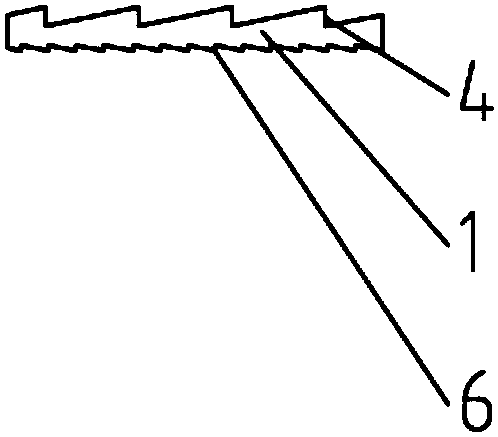

[0029] Such as Figure 1-3 As shown, a self-locking bolt includes a bolt body and a washer 1, the bolt body includes a bolt head 2 and a screw rod 3 connected to each other, the washer 1 is sleeved on the screw rod 3, and the end of the bolt head 2 in contact with the washer 1 There are a plurality of first helical teeth, and the end of the washer 1 in contact with the bolt head 2 is provided with a second helical tooth matching the first helical teeth; the first helical teeth are provided with a loosening thrust surface 5, that is, a bolt When the body is loosened and rotated, the first helical tooth is used as a force-giving surface, and the angle between the loosening thrust surface 5 and the horizontal plane is greater than the thread lift angle of the screw 3, so that the upward lifting distance of the bolt body is greater than the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com