Green dust-reducing environment-friendly construction structure for road and construction method thereof

A green, dust-reducing technology, applied in chemical instruments and methods, solid separation, sieves, etc., can solve the problems of low filtration accuracy, poor dust-reducing effect, and high manufacturing costs, achieve high filtration accuracy, low manufacturing costs, and avoid accidents. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

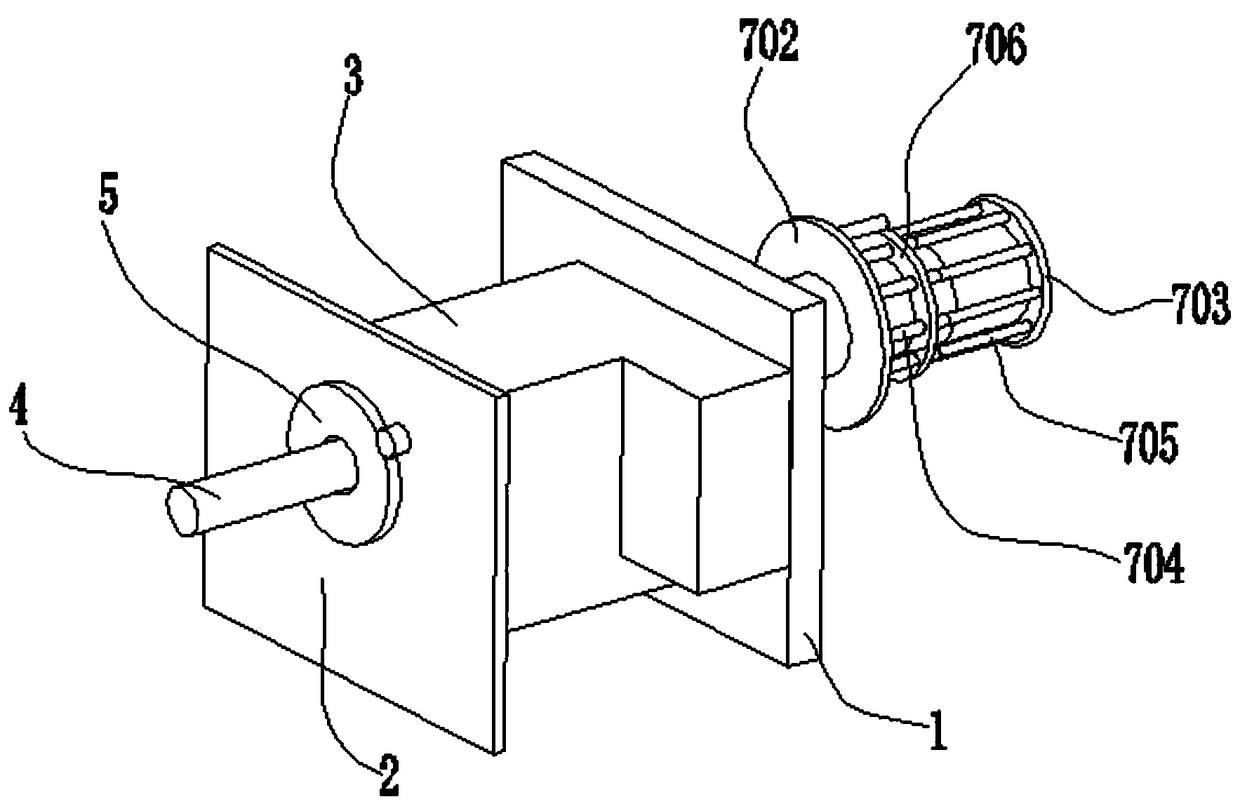

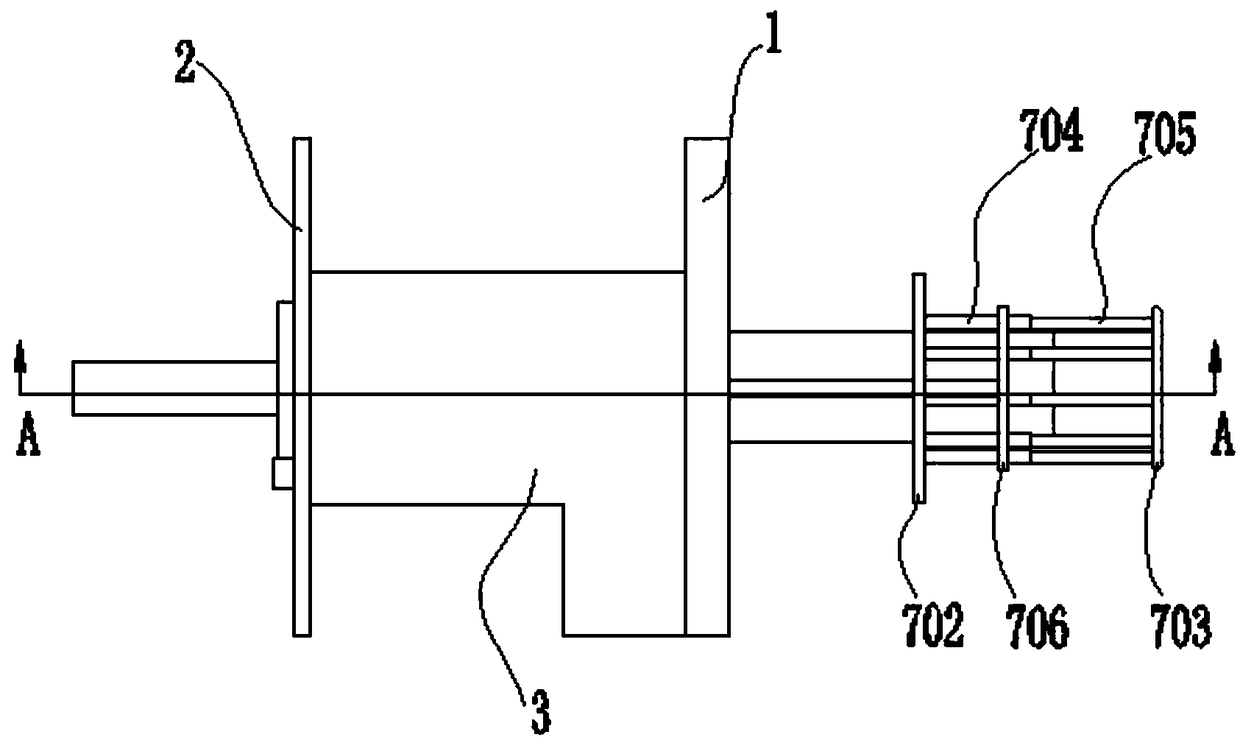

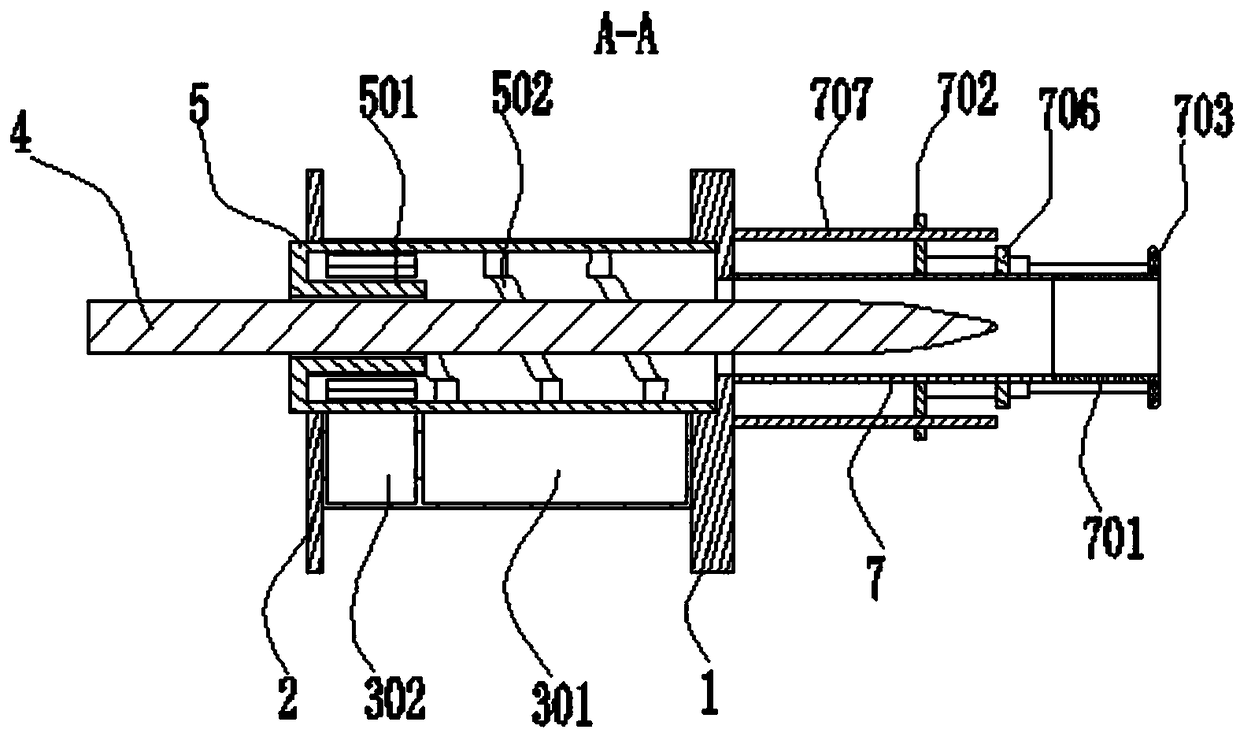

[0043] Such as figure 1 with figure 2 As shown, a road green dust reduction and environmental protection construction structure includes a drill bit 4, a dust suction device, and a first support plate 1 with a through hole in which the drill bit 4 can be inserted freely. The first support plate 1 serves as a supporting platform. An intake pipe 7 with the same inner diameter and through hole is provided on the side. One end of the intake pipe 7 is connected to the through hole of the first support plate 1, and the other end of the intake pipe 7 is connected with a buffer pipe 701. The buffer pipe 701 can be a hose or a buffer pipe. The other end of 701 is connected with an elastic edge 703, and the outside of the intake pipe 7 is sleeved with a push ring 702, which is used to push the elastic edge 703, and the dust suction device is connected with the inner space of the intake pipe 7. In this embodiment, the power The device drives the push ring 702 to move laterally. The push r...

Embodiment 2

[0046] Same as Example 1, the difference is: image 3 with Figure 5 As shown, a second support plate 2, a sieve tube 5 and a collecting device 3 are also provided. The second support plate 2 is arranged in parallel with the first support plate 1. As a supporting platform, one end of the sieve tube 5 is connected to the first support plate 1. Rotational connection, the other end passes through the second support plate 2 and is meshed and connected with gears installed on the second support plate 2 through teeth arranged on the outside; the inside of the collecting device 3 is a hollow structure, and the screen cylinder 5 is located in the aggregate Inside the device 3, along the direction from the first support plate 1 to the second support plate 2, the side of the screen cylinder 5 is provided with a first screen hole and a second screen hole in sequence, the size of the second screen hole is larger than the first screen hole The inside of the screen cylinder 5 is provided with...

Embodiment 3

[0051] A construction method for a road green dust reduction and environmental protection construction structure adopts the road green dust reduction and environmental protection construction structure in Embodiment 2. The following is a specific construction description of the deep foundation pit supporting structure at the junction of bridges and tunnels.

[0052] A construction method of a highway green dust reduction and environmental protection construction structure, and its steps are:

[0053] a. Now work on a rock with uneven sides. The push ring 702 pushes the elastic edge 703 into close contact with the side of the rock. The ratio of the non-contact area of the elastic edge 703 to the rock is less than 15%;

[0054] b. The drill bit 4 performs drilling operations on the rock. The dust suction device sucks the dust generated during the drilling into the intake pipe 7 and enters the screen tube 5, the screen tube 5 rotates, and the push screw 502 pushes the dust to the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com