Worm gear transmission mechanism and internal mixer thereof

A transmission mechanism, worm gear technology, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of broken teeth, high cost, inconvenient replacement and disassembly, etc., to increase the contact area and contact stiffness, reduce teeth The effect of surface wear and easy replacement and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

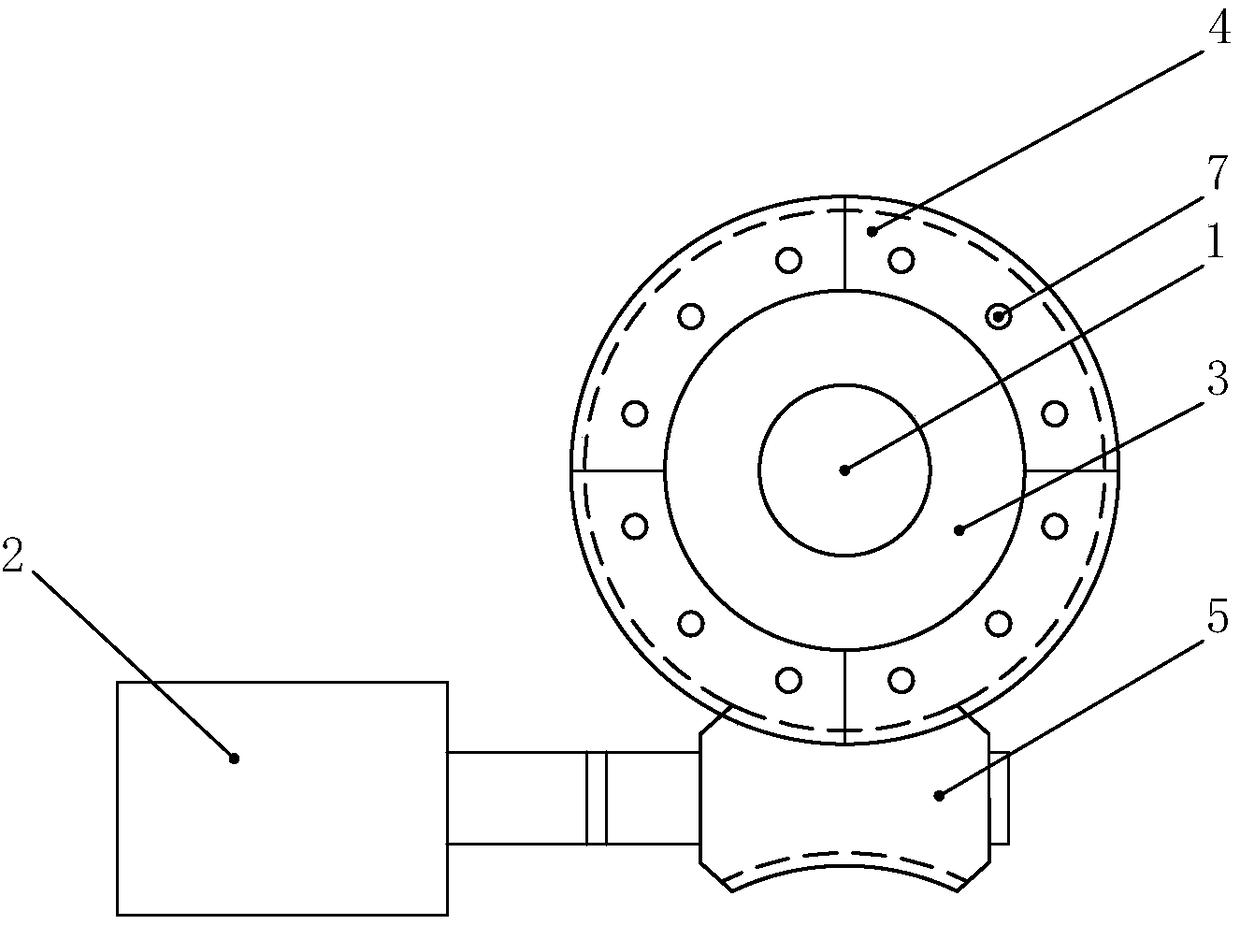

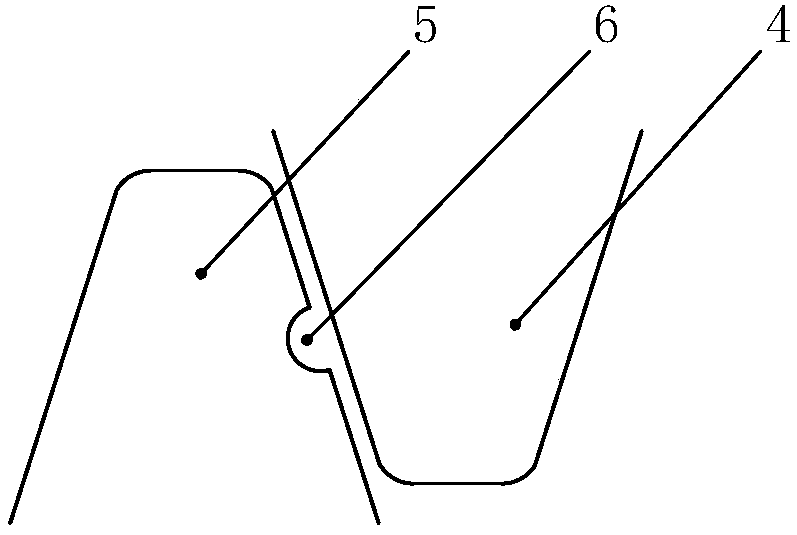

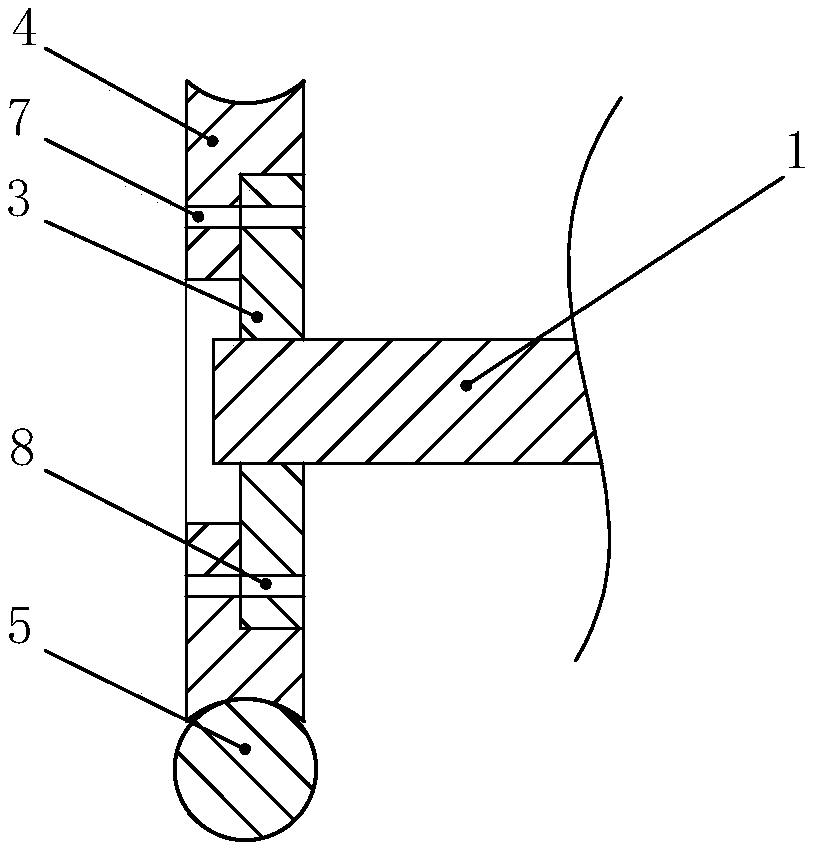

[0027] A worm and gear transmission mechanism, including a rotating shaft 1 and a driving motor 2, the rotating shaft 1 is sheathed with a worm gear, characterized in that: the worm gear includes a gear seat 3 sleeved on the rotating shaft 1 and a gear seat 3 sleeved on the rotating shaft 1 The toothed ring 4 on the top, the tooth seat 3 and the toothed ring 4 are detachably connected, the axial tooth profile of the toothed ring 4 is an inwardly concave arc-shaped structure, and the toothed ring 4 is meshed with a toroidal worm 5. One end of the toroidal worm 5 is connected to the output shaft of the driving motor 2 through a coupling. When the tooth surface on the toothed ring 4 is severely worn, only the toothed ring 4 needs to be replaced, which effectively saves the replacement cost of the worm gear. At the same time, when the toothed ring 4 is meshed with the toroidal worm 5, since the axial tooth profile of the toothed ring 4 is arc-shaped, the contact area between the t...

Embodiment 2

[0034] The structure of this embodiment is basically the same as that of Embodiment 1, the difference being that the toothed ring 4 in this embodiment is an annular structure divided into two or more. When the tooth surface of the worm gear is severely worn, it is only necessary to replace the equally worn geared ring 4 , which can further reduce the replacement cost of the worm gear.

Embodiment 3

[0036] The structure of this embodiment is basically the same as that of Embodiment 1, the difference being that the toothed ring 4 of this embodiment is an annular structure divided into two or more, and the inner wall of the toothed ring 4 is provided with an axial positioning groove. The structure is: the middle part of the inner wall surface of the toothed ring 4 is radially outwardly recessed to form a slot 11, the cross section of the slot 11 is a U-shaped structure, and the toothed ring 4 is clamped on the tooth seat 3 through the slot 11 On the outer edge of the slot 11 , the through holes 7 are symmetrically arranged on both side walls of the slot 11 .

[0037] At the same time, in order to prevent the gap between the toothed ring 4 and the tooth seat 3 in the axial direction and affect the transmission stability of the worm wheel and the toroidal worm 5, the distance between the two side walls of the locking groove 11 is less than or equal to that of the tooth seat 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com