Two-phase flow interface parameter measuring method

A technology of interface parameters and measurement methods, applied in the direction of measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

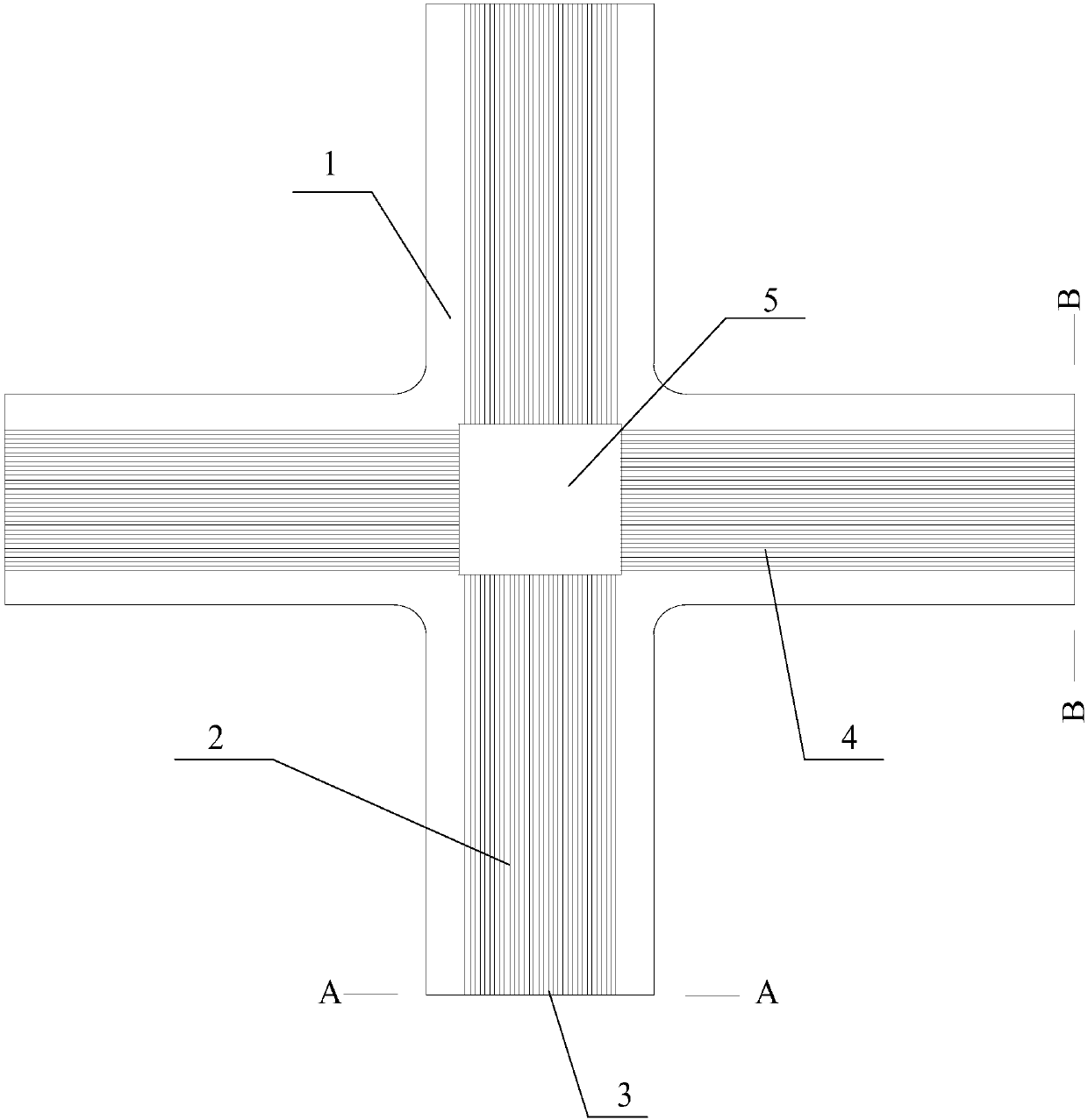

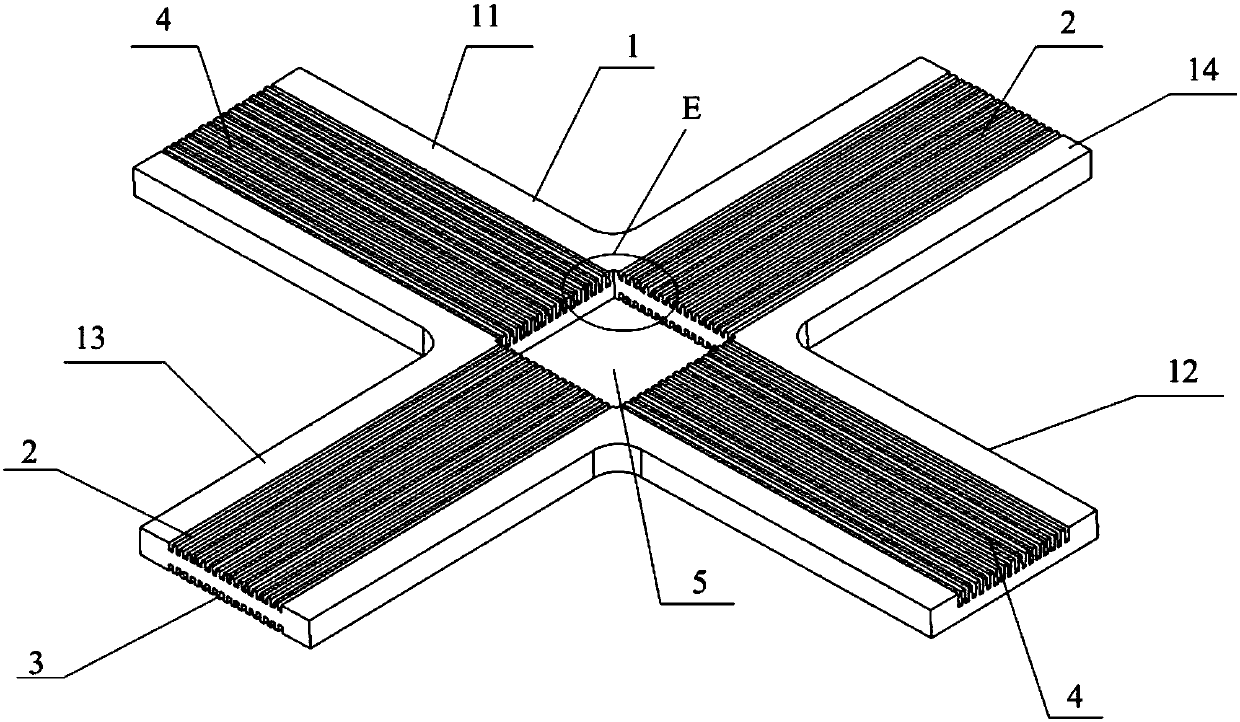

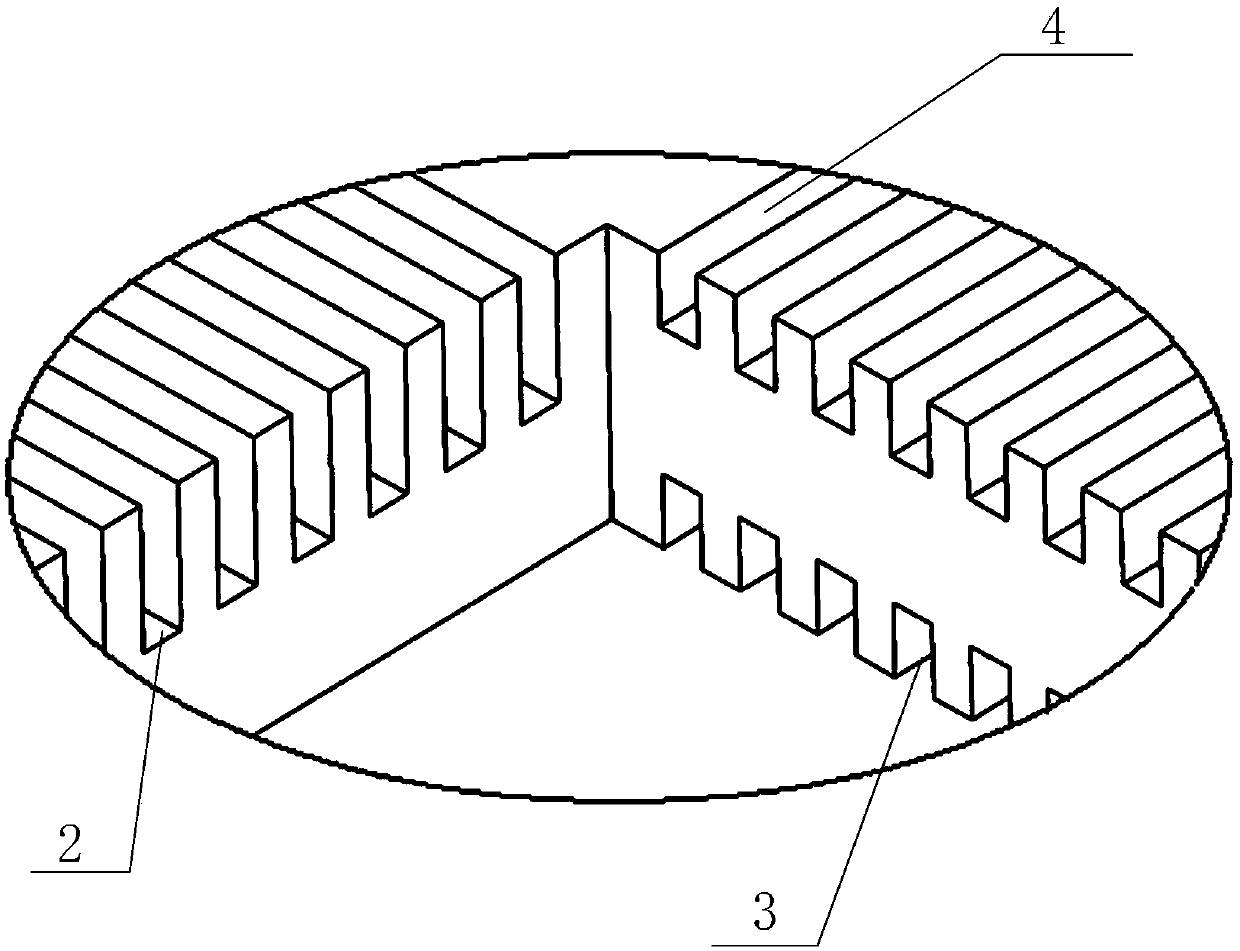

[0121] In this embodiment, a phase detector for measuring the phase distribution signal of the cross-section of the flow channel under transient working conditions is provided.

[0122] Such as Figure 1-Figure 8 As shown, the phase state detector includes a substrate 1, and the center of the substrate 1 is provided with a flow channel hole 5 penetrating the upper and lower surfaces of the substrate 1. The axial direction of the flow channel hole 5 is a vertical direction, and the flow channel hole 5 is provided with 3 There are three electrode wire layers, which are respectively the upper electrode wire layer, the middle electrode wire layer and the lower electrode wire layer, and the plane where each electrode wire layer is located is perpendicular to the central axis of the flow channel hole 5 . Each electrode wire layer includes a plurality of electrode wires arranged in parallel and located in the same plane, and the electrode wires in each electrode wire layer are evenly...

Embodiment 2

[0149] In this embodiment, a measurement system for the cross-section full-field interface parameters in two-phase flow experiments under transient conditions is provided to ensure real-time, accurate and stable measurement of cross-section full-field interface parameters under transient conditions. The in-depth study of two-phase flow under working conditions provides data support. Such as Figure 9 As shown, the two-phase flow interface parameter measurement system includes an excitation signal control unit, a phase detection device and a receiving signal processing unit, and the phase detection device is the phase detector in Embodiment 1; the middle part of the phase detector The electrode wires of the electrode wire layer are used as excitation electrode wires 6 for transmitting excitation signals in the measurement of two-phase flow interface parameters, and the electrode wires of the upper electrode wire layer and the lower electrode wire layer are used as receiving ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com