Waistband structure and underpant thereof

A belt and chain knitting technology, applied in underwear, applications, clothing, etc., can solve the problems of poor air permeability, difficult to drain sweat from the waist, narrow belt, etc., and achieve the effects of good moisture conduction, not easy to flange, and low pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

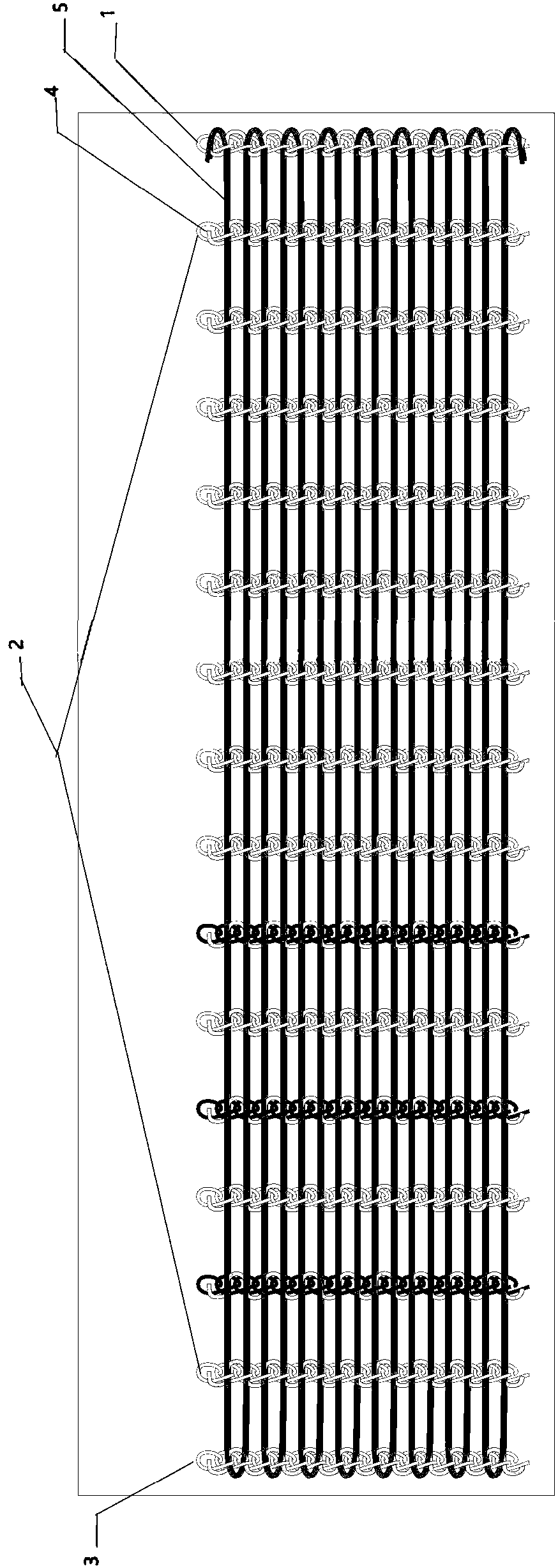

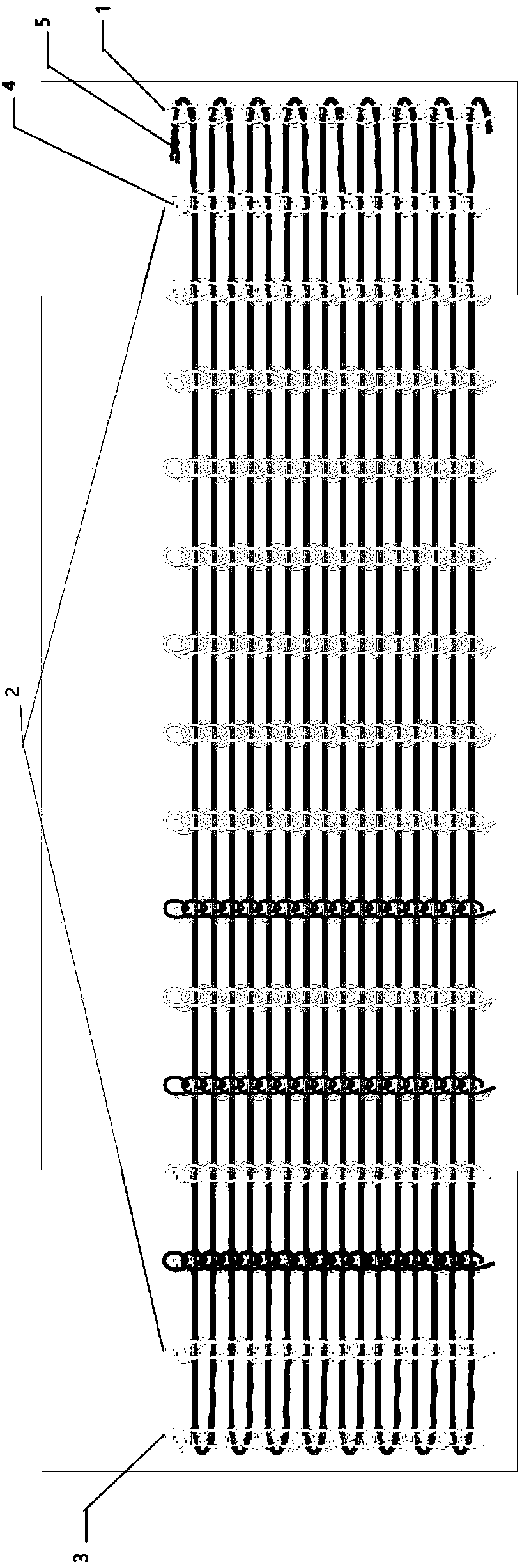

[0016] Such as figure 1 , 2 As shown, a belt structure of the present invention, the basic organization is a chain organization, including a first edge chain 1, several middle chains 2, a second edge chain 3, the first edge chain 1, several The middle knitting chain 2 and the second edge knitting chain 3 are all vertically arranged side by side, and the first edge knitting chain 1 is the starting knitting chain, and several middle knitting chains 2, the second side knitting chains are arranged side by side successively from the starting point to the other side. The two edge knitting chains 3 are all covered with an elastic yarn 4 on all the first edge knitting chains, the middle knitting chains and the second edge knitting chains.

[0017] Further, the elastic yarn is threaded into and out of the front side of the first coil of the knitting chain, and then passed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com