Large high-precision industrial robot balance cylinder

An industrial robot and high-precision technology, applied in the field of balancing cylinders, can solve the problems of reduced practicability of balancing cylinders, unusable balancing cylinders, and short service life, and achieve the effects of increasing service life, being less prone to fatigue failure, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

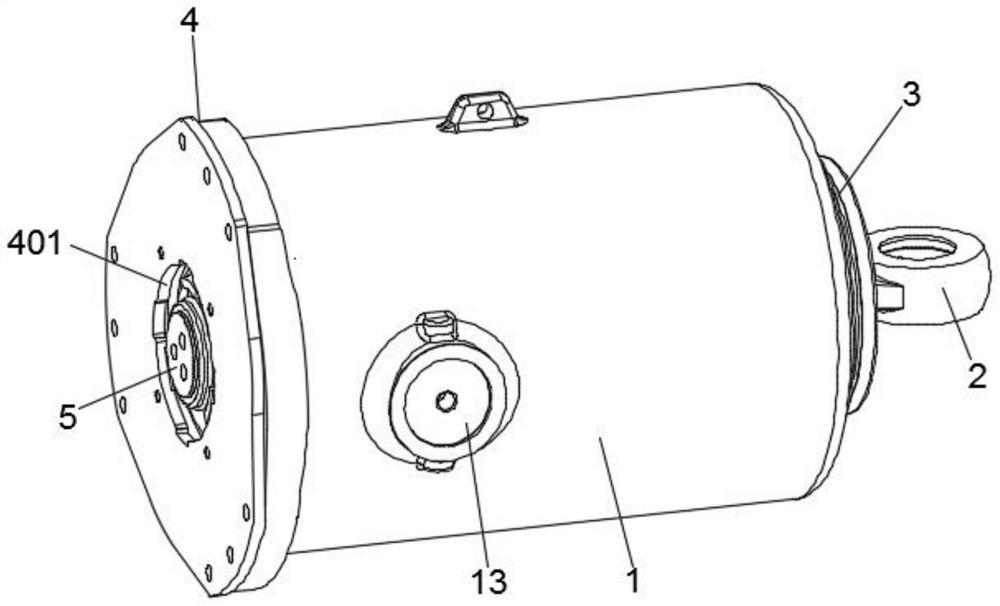

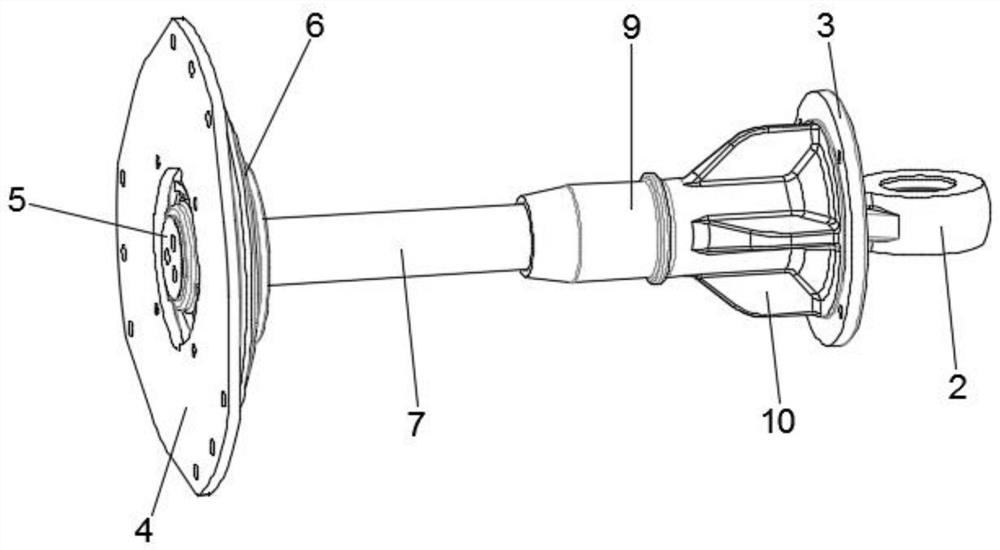

[0028] like Figure 1-7 As shown, a large-scale high-precision industrial robot balance cylinder, including

[0029] Housing 1, an end cover 4 is fixedly installed on one side of the housing 1, a bearing base 3 is fixedly installed on the other side of the housing 1, and a connecting ear 2 is provided on the side of the bearing base 3 away from the housing 1, A connecting rod 11 is fixedly installed on the side of the connecting ear 2 close to the bearing base 3, and a connecting sleeve 9 is fixedly installed on the side of the bearing base 3 away from the connecting ear 2, and a pull rod 7 is sleeved in the connecting sleeve 9. One end of the tie rod 7 located inside the connecting sleeve 9 is threadedly connected with the connecting rod 11;

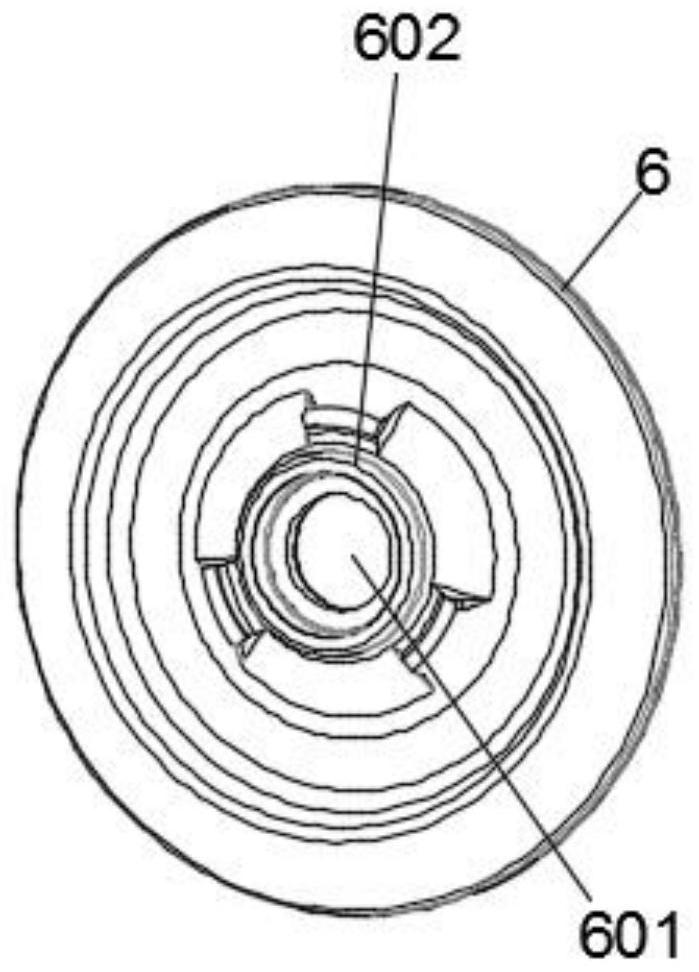

[0030] The housing 1 is provided with a moving plate 6 on the side away from the bearing base 3, the middle part of the moving plate 6 is provided with a socket 601, and the middle part of the moving plate 6 near the end cover 4 is pro...

Embodiment 2

[0034] like Figure 1-8 Shown; a large-scale high-precision industrial robot balance cylinder, including

[0035] Housing 1, an end cover 4 is fixedly installed on one side of the housing 1, a bearing base 3 is fixedly installed on the other side of the housing 1, and a connecting ear 2 is provided on the side of the bearing base 3 away from the housing 1, A connecting rod 11 is fixedly installed on the side of the connecting ear 2 close to the bearing base 3, and a connecting sleeve 9 is fixedly installed on the side of the bearing base 3 away from the connecting ear 2, and a pull rod 7 is sleeved in the connecting sleeve 9. One end of the tie rod 7 located inside the connecting sleeve 9 is threadedly connected with the connecting rod 11;

[0036] The housing 1 is provided with a moving plate 6 on the side away from the bearing base 3, the middle part of the moving plate 6 is provided with a socket 601, and the middle part of the moving plate 6 near the end cover 4 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com