Sensor preparation liquid and application thereof

A sensor and cable-type technology, applied in the field of materials, can solve the problems of narrow monitoring area, misjudgment of monitoring results, networking and information interference, etc., and achieve the effect of improving the scope of application and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

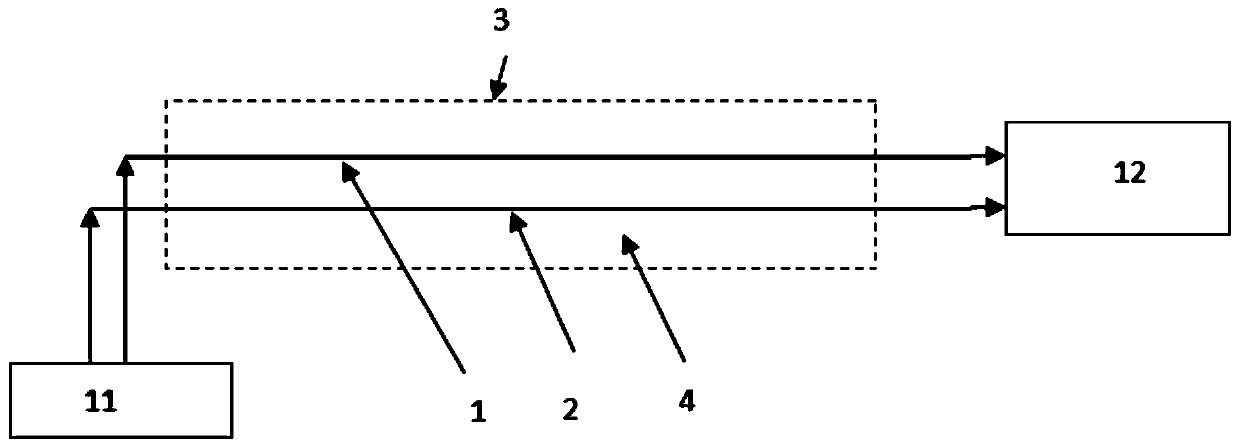

[0058] like figure 1 As shown, the cable sensor is a double-core cable sensor with a length of 20cm. The core 11 and the core 22 are used as the two endpoints of the output signal. The sensor material 4 is generated by solidifying the sensor preparation liquid. Sensor preparation liquid: piezoelectric powder 50%, epoxy resin 10%, magnetic sensitive material 15%, silicone 20%, binder 5%. The piezoelectric powder is potassium niobate (KNbO 3 ), the epoxy resin is cycloaliphatic epoxy resin, the silicone is room temperature vulcanized silicone rubber, the magnetic sensitive material is manganese zinc ferrite, and the adhesive is E-44 epoxy resin glue.

[0059] The signal generator 11 injects a test voltage signal into the cable sensor through the core 1 1 and core 2 2 terminals, and obtains the output voltage value and the frequency value of the output voltage signal through the collector 12 at the output terminal of the other end. The collectors 12 connected to the output term...

Embodiment 2

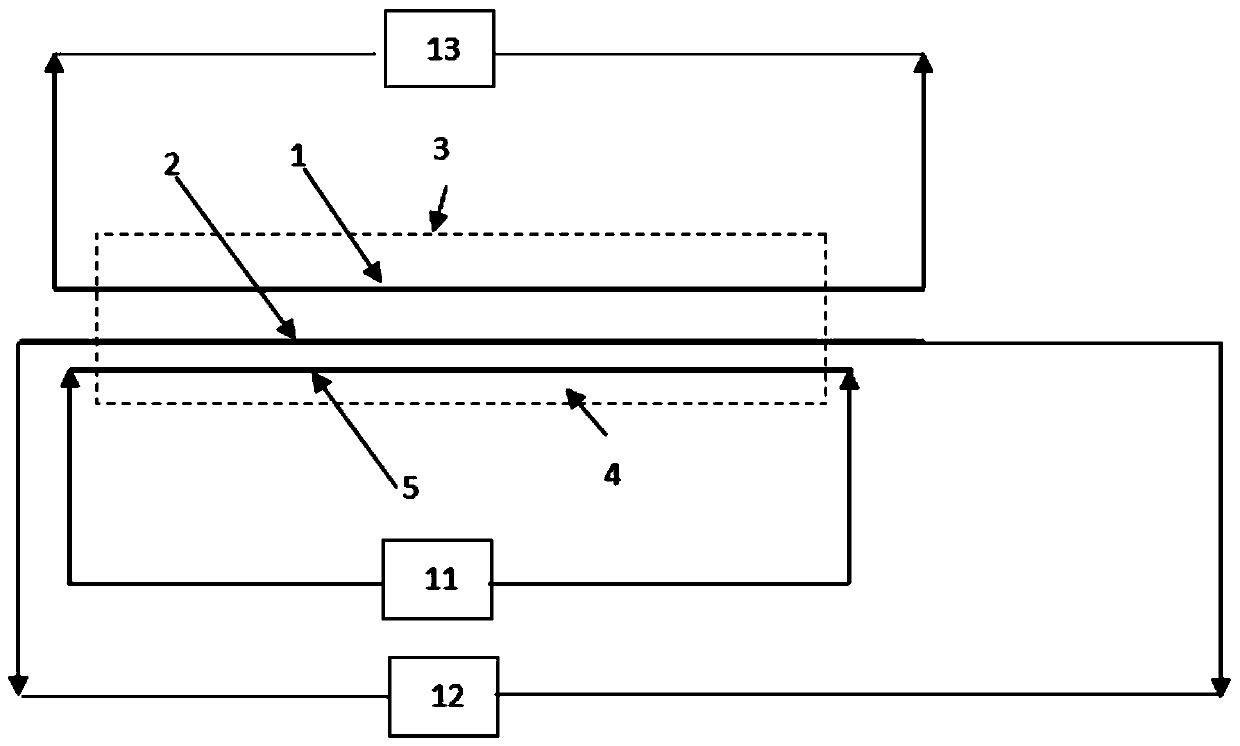

[0064] When the number of wire cores is large, multiple sensor outputs can be realized, such as figure 2 As shown, the difference from embodiment 1 is that a wire core 3 5 is added:

[0065] Assuming that the sensor test signal is 1MHz, the signal generator 11 injects it through the core 35, and under the action of the magnetic sensitive material and piezoelectric material inside the cable sensor, the high-frequency signal injected through the terminal of the core 3 passes through the piezoelectric material 4 of the sensor material. The material generates electrical-mechanical signal conversion, and at the same time, another wire core 2 2 generates mechanical-electrical signal conversion to obtain an electrical signal. It should be noted that due to electromagnetic field induction, when a high-frequency signal is injected into the terminal of the core 3, a coupling voltage is generated between the other two cores, and the coupling voltage is the same as the signal after the m...

Embodiment 3

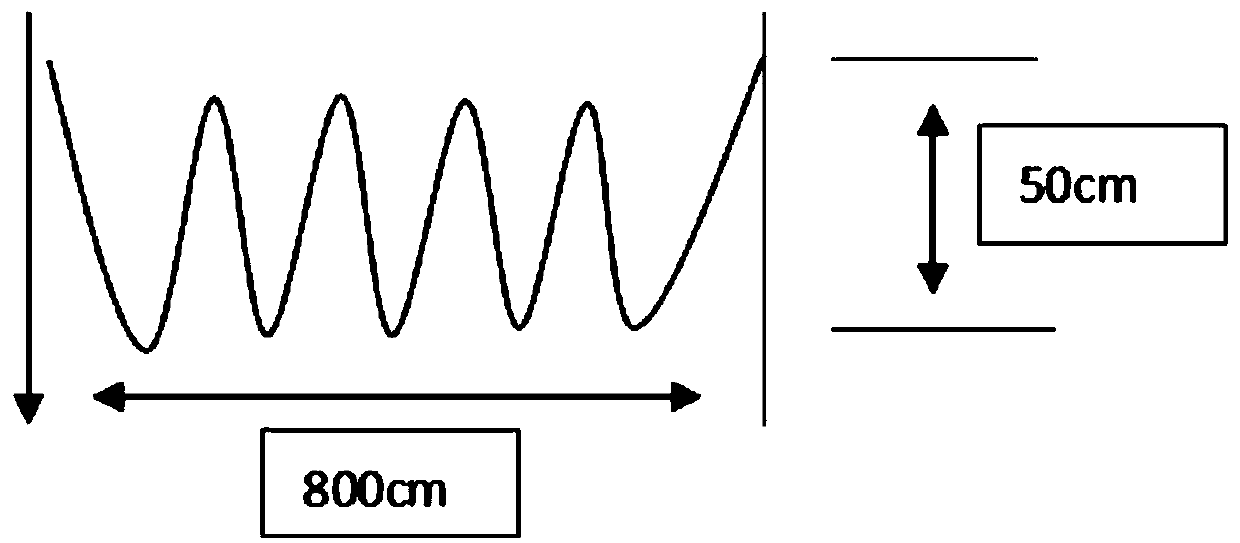

[0068] like image 3 As shown, the cable sensor has a single-core structure, and the sensor preparation solution is selected as: piezoelectric powder 70%, epoxy resin 10%, magnetic sensitive material 5%, silicone 10%, and binder 5%. The length of the cable sensor is 2000cm, and it is bent into the following shape. It is used as a curved cable sensor for bridge vibration monitoring. The external size is: 800cm×50cm.

[0069] Typically applied to bridge 21, the length of bridge 21 to be monitored is 8 meters, and the height is 0.5 meters. If according to the traditional point monitoring sensor, each point monitoring sensor monitors only 0.1 square meters, at least 40 point monitoring are required Sensors can achieve the purpose of precise monitoring. If there are too many sensors, it is obvious that various problems of information and power supply interconnection and installation between sensors will be introduced, which will affect reliability. Depend on Figure 4 As shown, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com