Shell tubular secondary spray condenser for cooling tower

A shell-and-tube cooling tower technology, applied in the field of cooling towers, can solve problems such as large floor area and overall volume, limited cooling efficiency of condensers, and inability to break through, so as to improve cooling effect, improve evaporative cooling efficiency, and wind strong cold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below with reference to the accompanying drawings. The description in this section is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

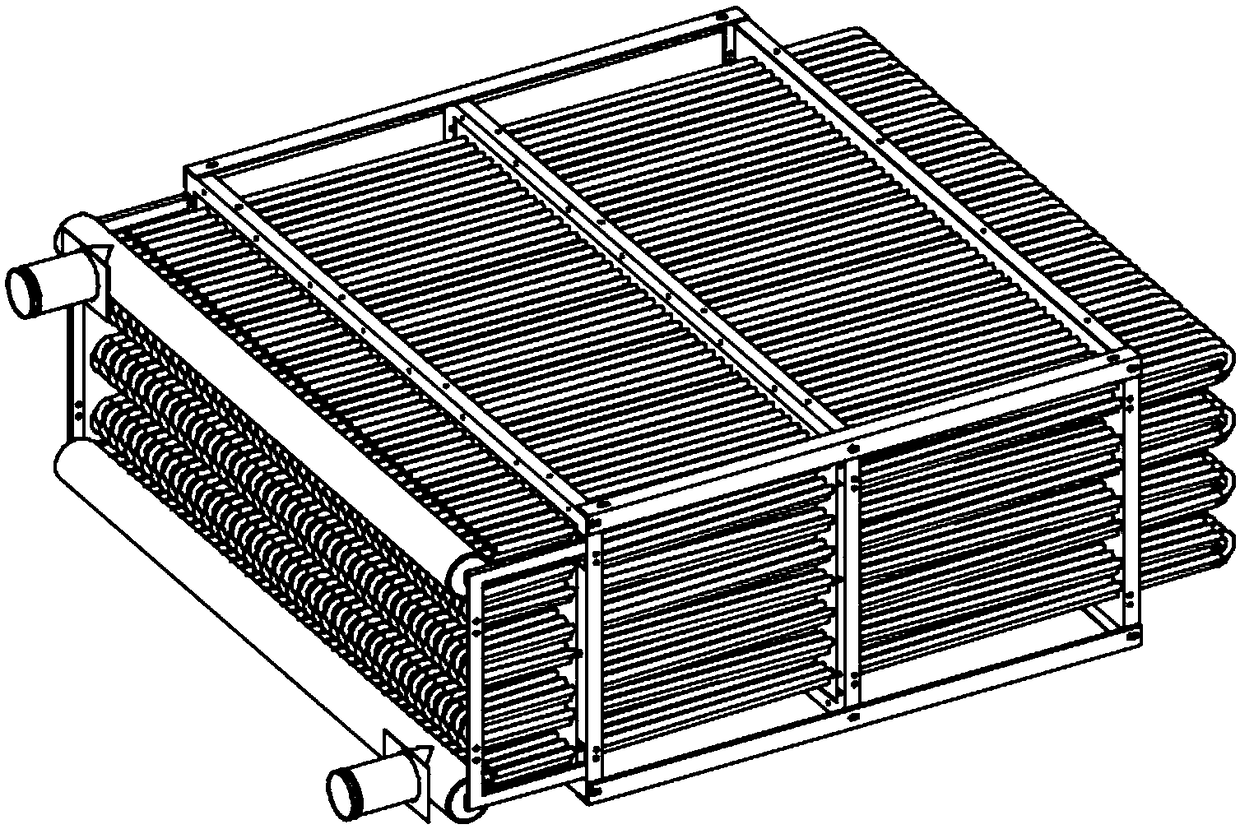

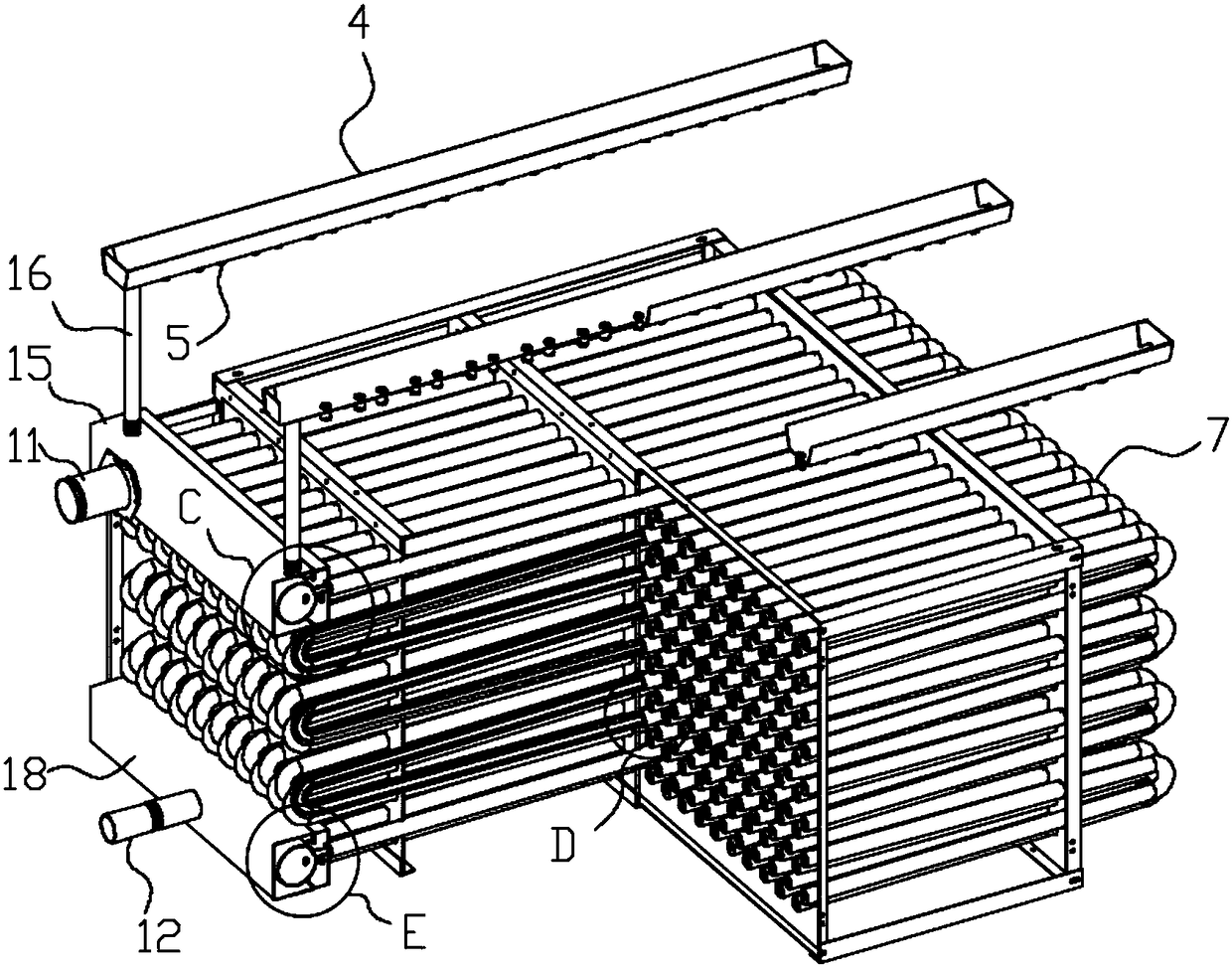

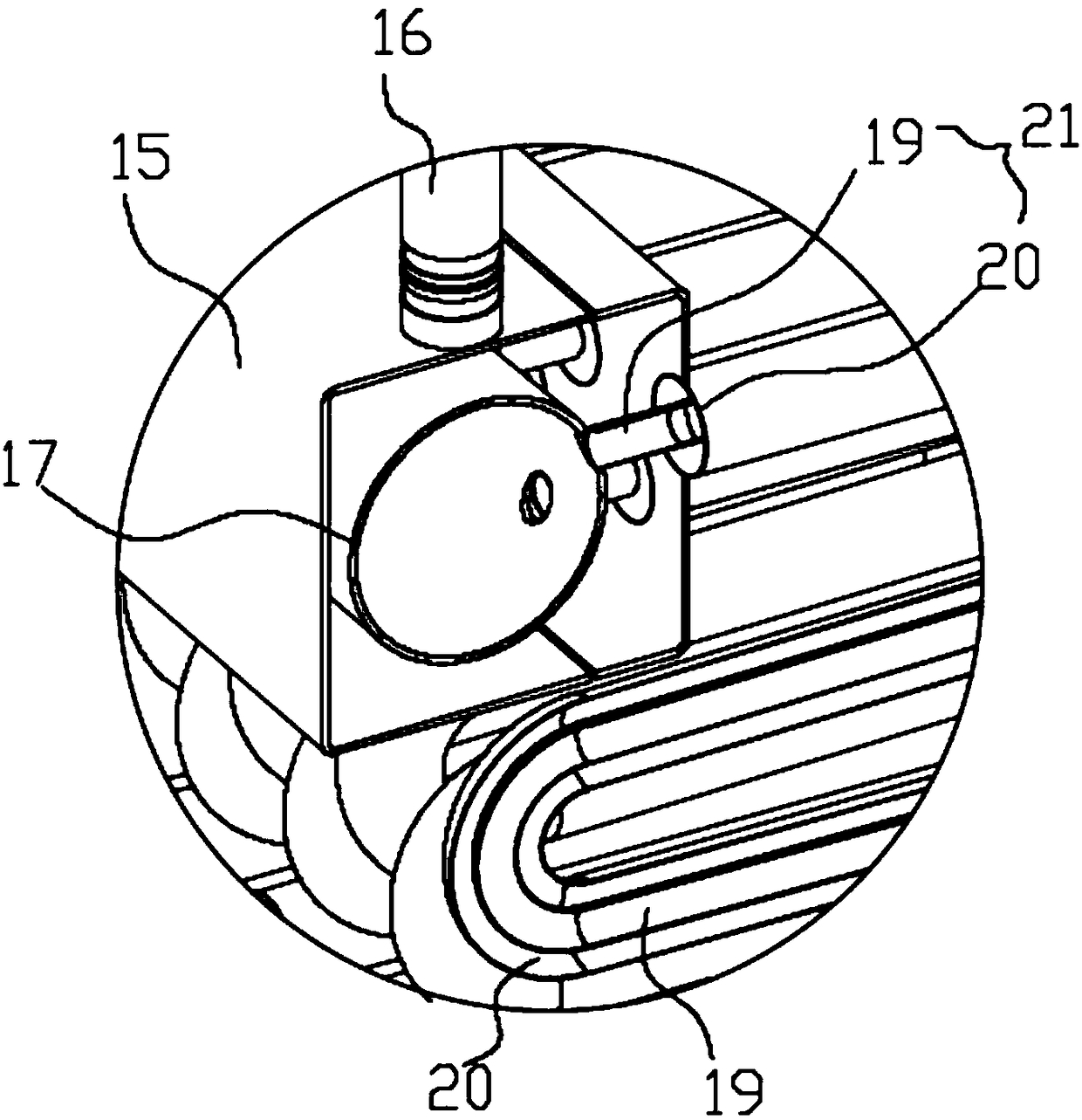

[0028] Such as Figure 2-Figure 10 As shown, the specific structure of the present invention is: a shell-and-tube secondary spray condenser for cooling towers, which includes rows of condensing coils 21, and the condensing coils 21 are double-layer pipes with a sandwich cavity. , Including the outer tube 20 of the outer layer and the inner tube 19 of the inner layer; the upper port of the outer tube 20 is connected to the upper water collecting cavity 15; the upper port of the inner tube 19 is connected to the upper collecting cavity 17; The upper collecting cavity 17 is arranged in the upper collectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com