Lithium battery flexibly packaged core base angle position damage detection mechanism

A damage detection and lithium battery technology, applied in the field of damage detection mechanism at the bottom corner of the soft-packed core of lithium batteries, can solve the problems of easy misjudgment, increased detection cost, unfavorable detection efficiency, etc., and achieves strong compatibility and convenient fixing and disassembly , the effect of a large detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The purpose of the present invention can be achieved through the following technical solutions:

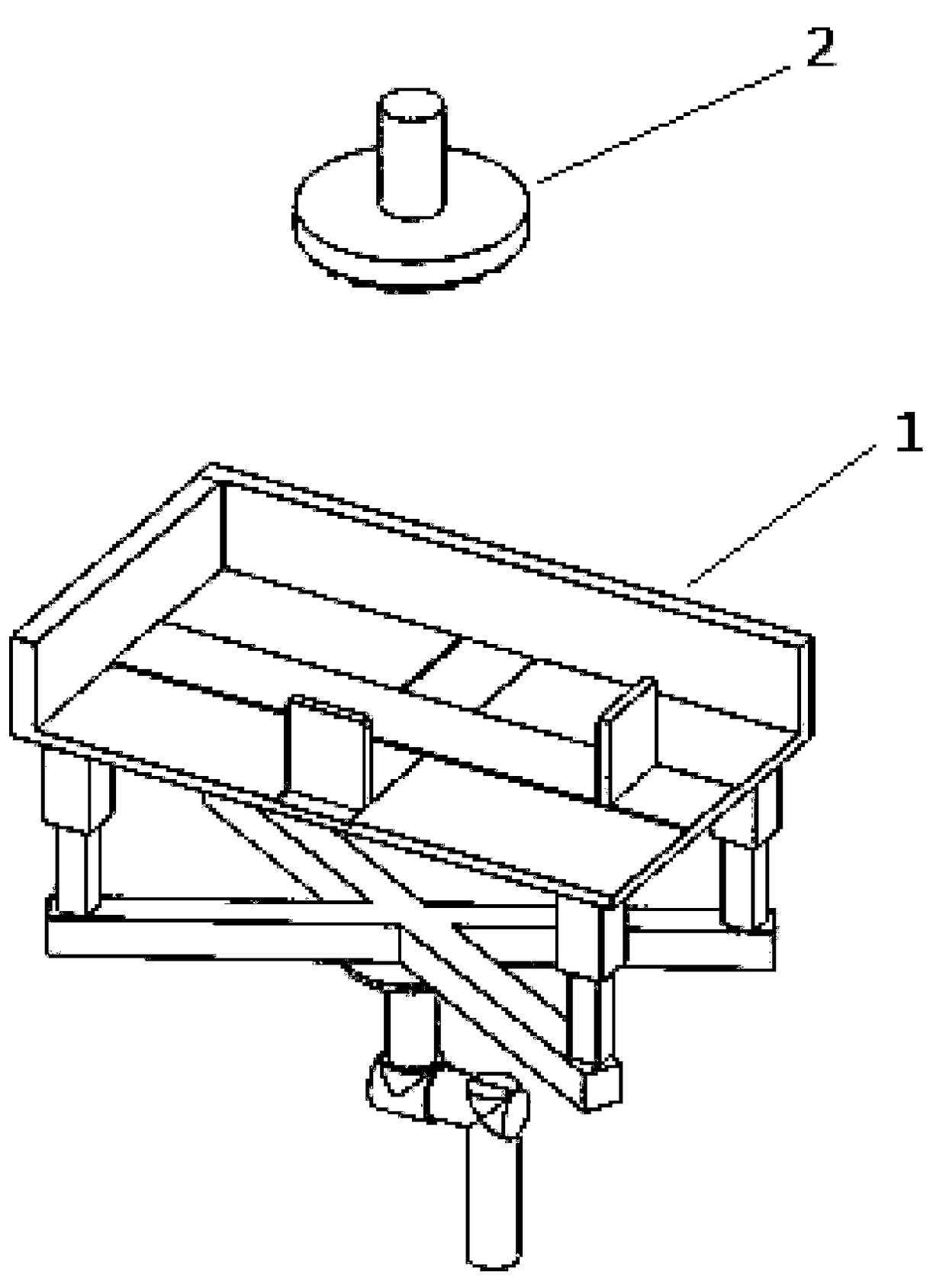

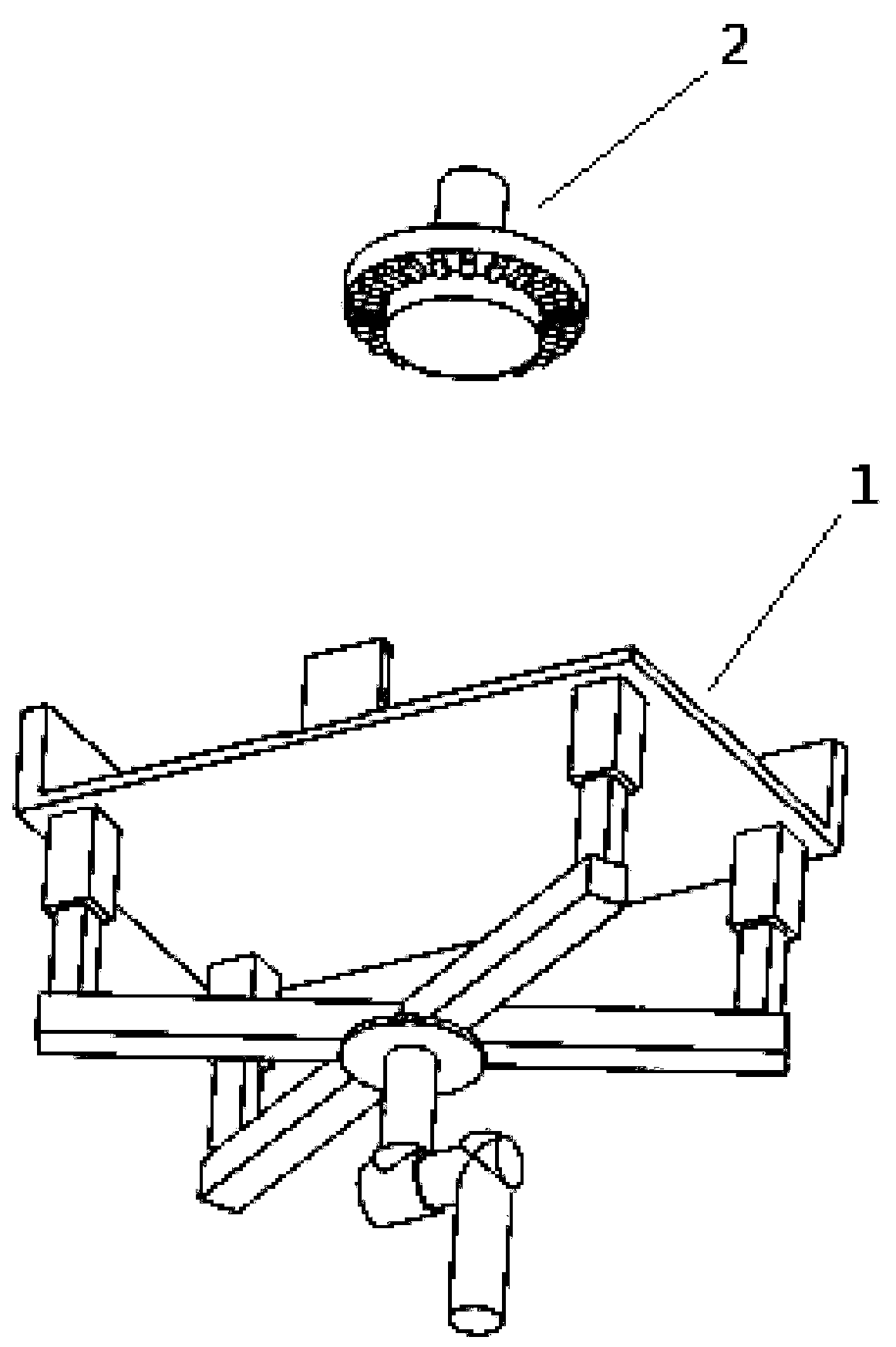

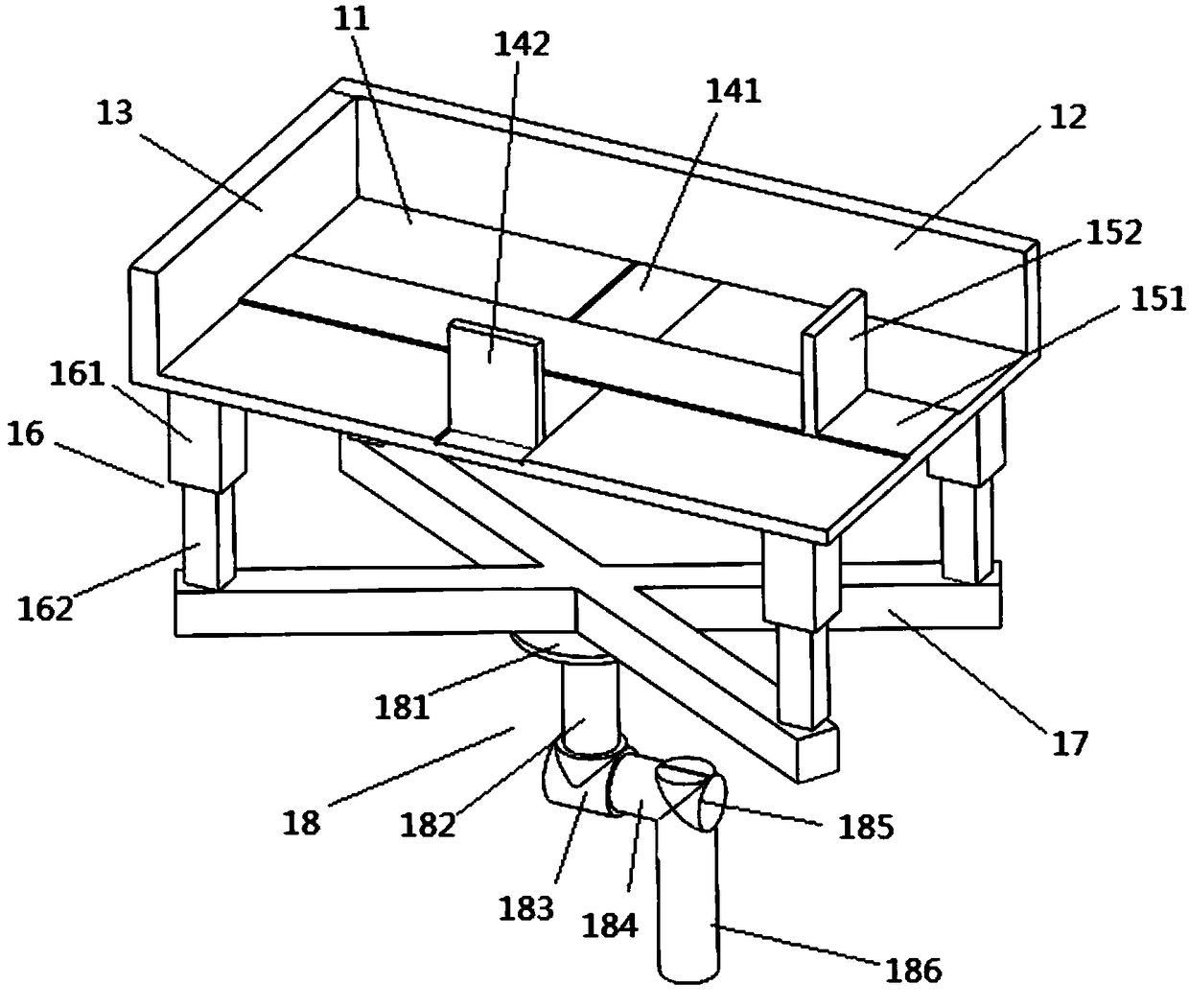

[0022] A damage detection mechanism for the bottom corner of the soft-packed lithium battery core, see Figure 1-4 , including a detection platform 1 and a detection camera 2;

[0023] A detection camera 2 is arranged above the detection platform 1, a horizontal adjustment column 16 is arranged at the bottom of the detection platform 1, a table base 17 is installed below the horizontal adjustment column 16, and a base supporting leg 18 is connected to the bottom of the table base 17;

[0024] The detection platform 1 includes a table top 11, a first fixed plate 12, a second fixed plate 13, a horizontal adjustment column 16, a table base 17, and a base support leg 18. Two fixed plates 13, the first fixed plate 12 and the second fixed plate 13 are perpendicular to the table top 11, and the two ends of the first fixed plate 12 and the second fixed plate 13 are connected; One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com