Rotary bee card manufacturing device

A production device and rotary technology, applied in animal husbandry and other directions, can solve problems such as disadvantage, time-consuming and labor-intensive, and improve work efficiency, and achieve the effect of good promotion and utilization value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

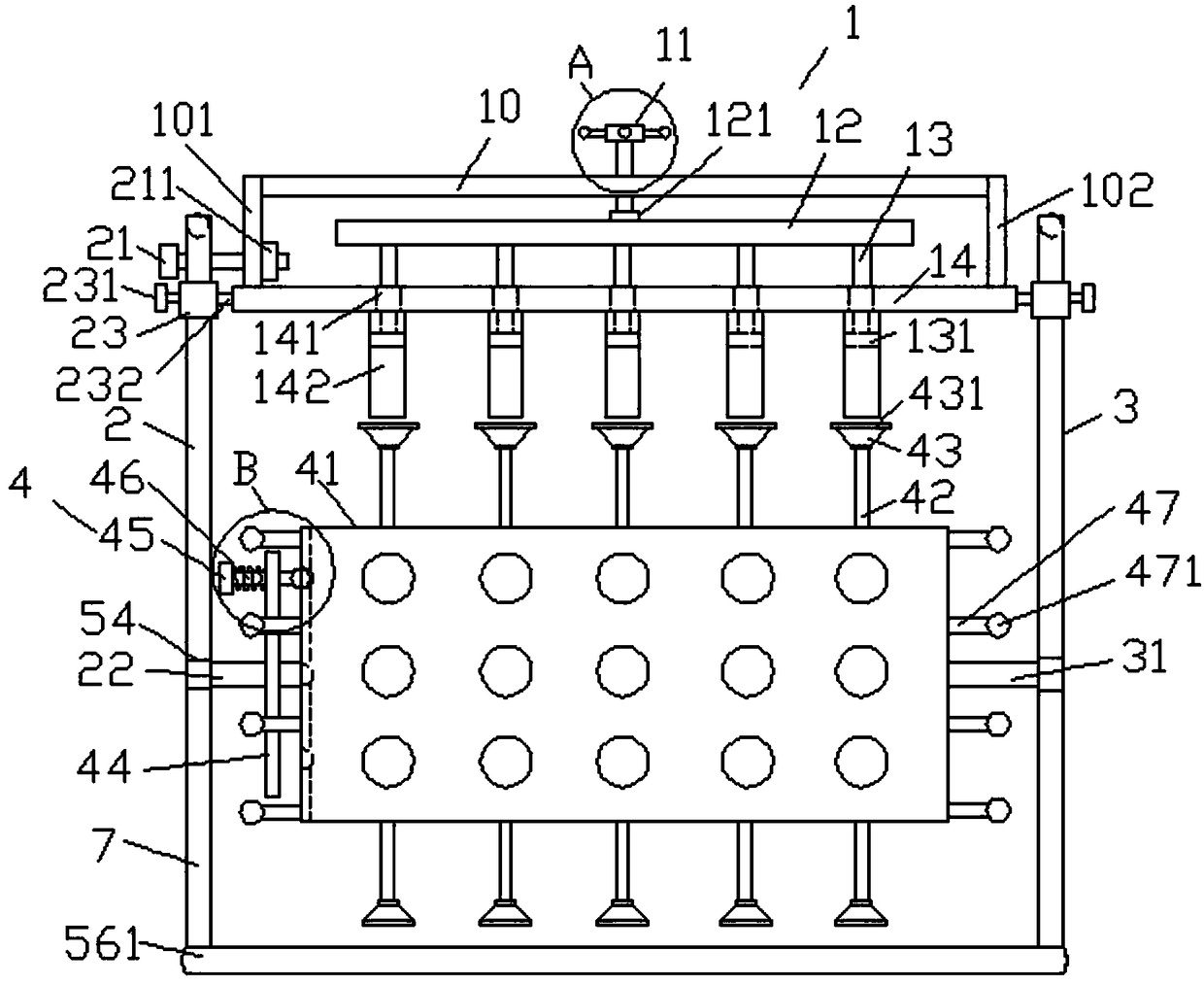

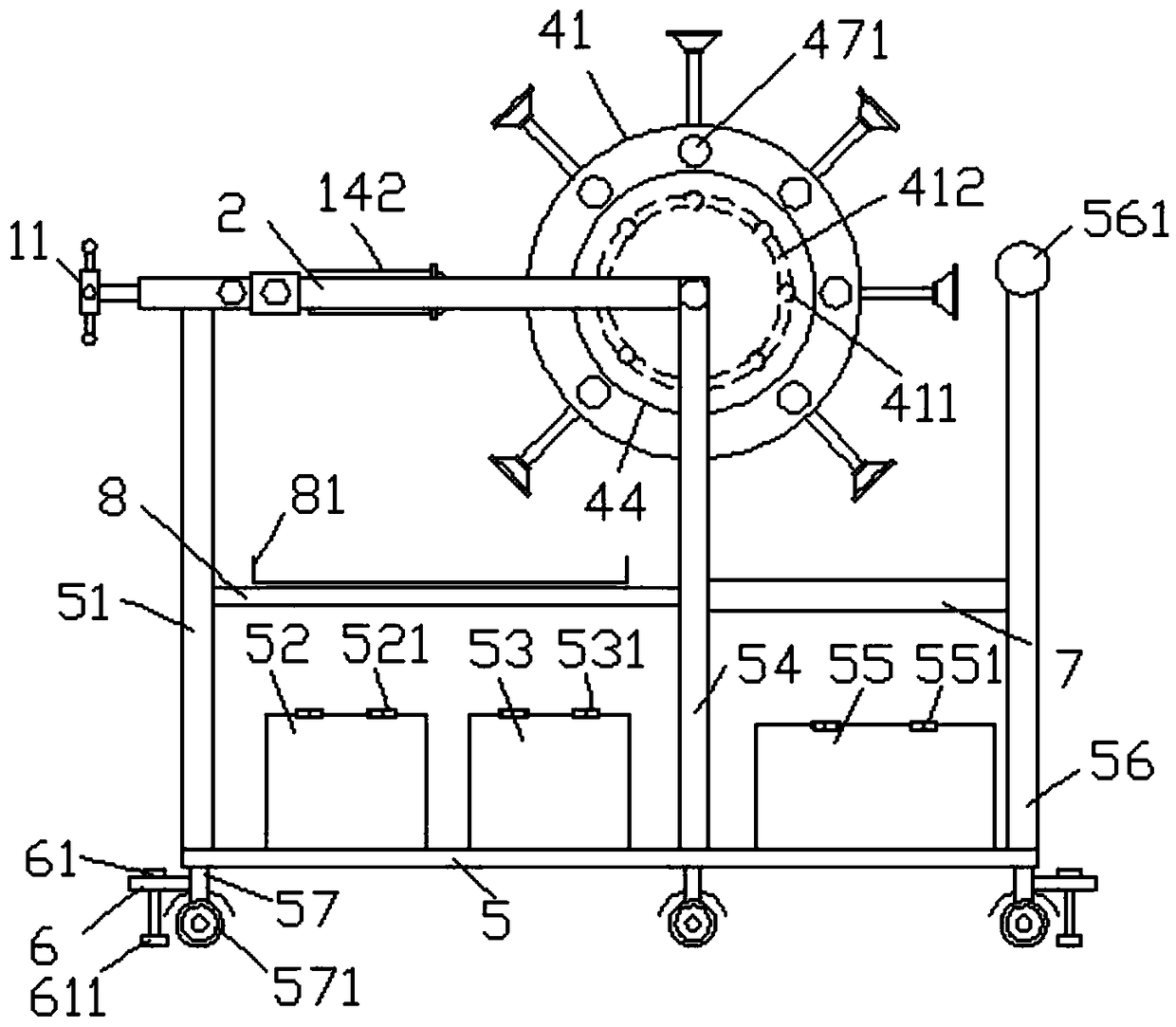

[0054] Such as Figure 1 to Figure 4 As shown, the structure of this kind of rotary bee card making device includes a pupa assembly, and the pupa assembly includes a first cross bar 2 and a second cross bar 3 arranged in parallel, and the first cross bar 2 and the second cross bar 3 are arranged in parallel. The first sleeves 23 are sleeved on the second crossbars 3 respectively, and the first bolts 231 are screwed inwardly on the outside of the first sleeves 23. The two ends of a horizontal plate 14 are hinged, and the inner side of the first horizontal plate 14 is fixedly provided with a plurality of second sleeves 142 with openings at both ends. The through hole 141, the second sleeve 142 is respectively provided with a piston 131, the outer end of the piston 131 is fixedly connected with the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com