Online type bulb lamp illuminating and dimming testing machine

A bulb lamp and testing machine technology, applied in sorting and other directions, can solve the problems of inability to meet production requirements, difficult to control error rate, high labor cost, etc. The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

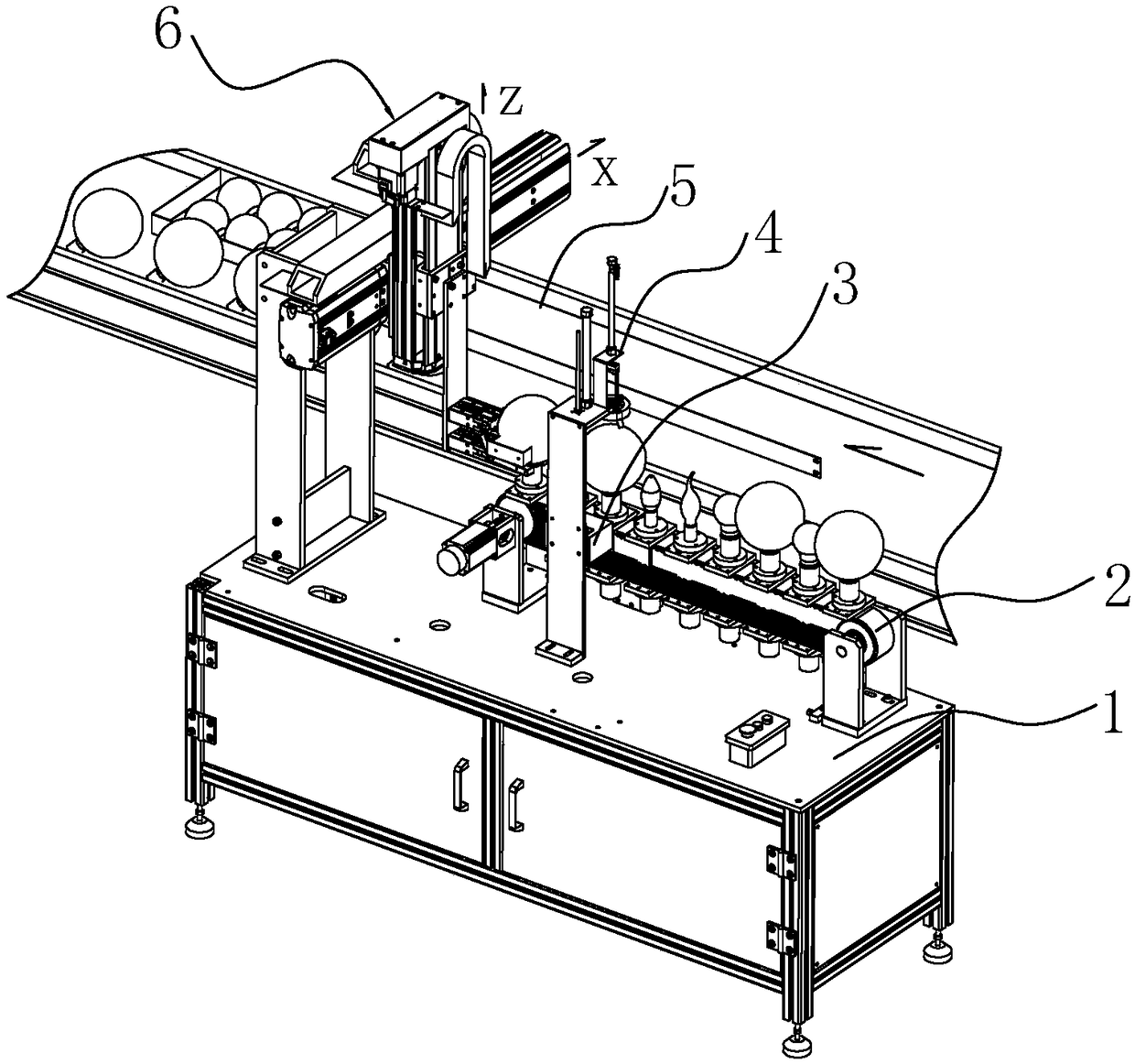

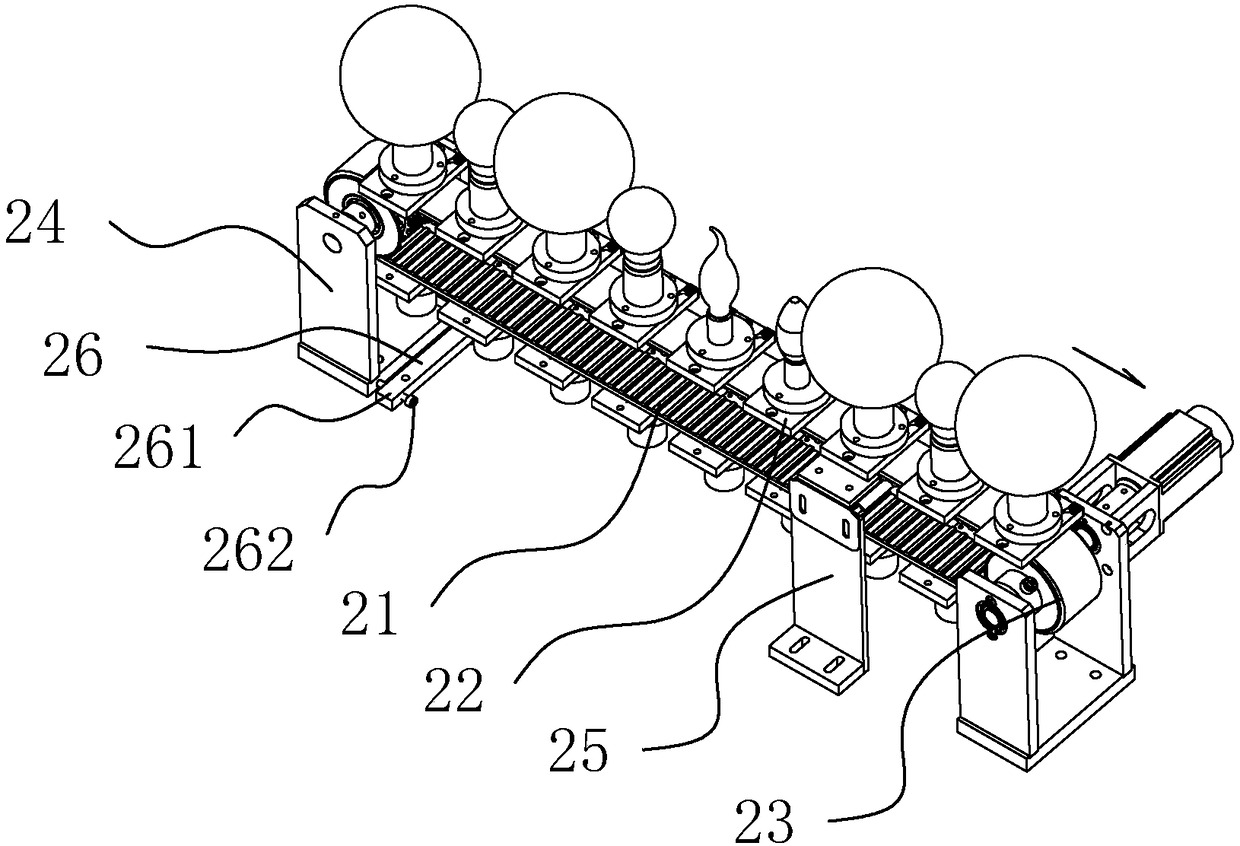

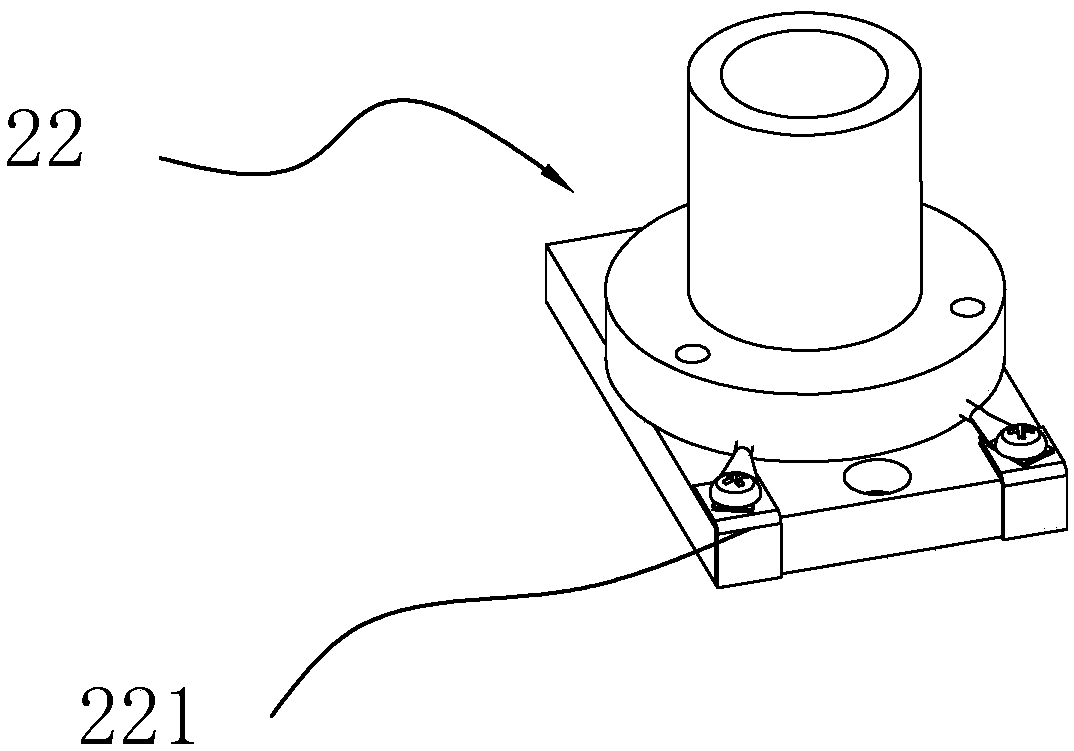

[0024] In order to solve the problems of the technologies described above, the technical solution of the present invention is: Figure 1~4 As shown, an online lighting and dimming testing machine for bulb lamps includes a frame 1, a transmission device 2, a testing device 3, a positioning device 4, and a sorting conveyor belt 5, wherein the transmission device is used for the LEDs to be tested. The lamps are accurately sent to the test device. The transmission device includes a synchronous device 21. A number of lamp holders 22 for placing LED lamps are arranged at equal intervals on the outer surface of the synchronous belt. The lamp holders can also be used according to different The model of the LED lamp is adapted, and the lamp holder is provided with a conductive contact 221; an active synchronous wheel device 23 and a driven syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com