Scraper type plate material separating device

A scraper type, sheet material technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems affecting the normal use of the production line, high surface tension, low production efficiency, etc., to ensure service life, strong versatility, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

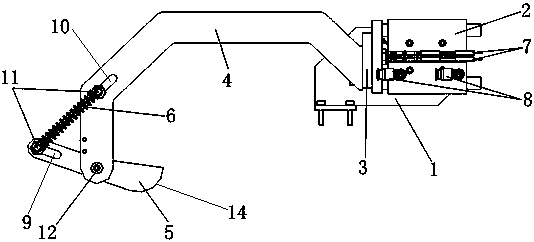

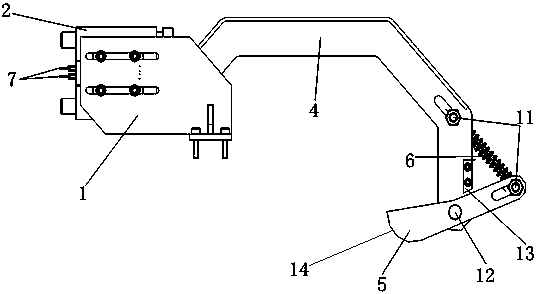

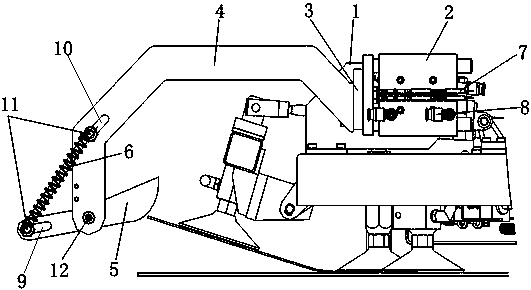

[0018] A scraper-type sheet material splitting device, including a guide cylinder 2 installed on a support 1, a connecting plate 3 is installed at the front end of the piston rod of the guide cylinder 2, and a downward bending plate is installed at the front end of the connecting plate 3 A curved arm 4, the lower end of the curved arm 4 is hinged with a scraper 5, the rear end of the scraper 5 is connected to one end of a spring 6, the other end of the spring 6 is connected to the curved arm 4, and the front end of the scraper 5 is in contact with the sheet material. The curved surface 14 is provided with several serrations.

[0019] As a further improvement of the above technical solution, a proximity switch 7 is installed on the outer wall of the guide cylinder 2 .

[0020] As a further improvement of the above technical solution, a one-way throttle valve 8 is installed at the air intake hole of the pilot cylinder 2 .

[0021] As a further improvement of the above technical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com