Direct-flow scavenging engine cylinder liner with variable scavenging phase, direct-flow scavenging engine cylinder liner component with variable scavenging phase and direct-flow scavenging engine with variable scavenging phase

A technology for engine cylinders and cylinder liners, which is applied to engine components, combustion engines, machines/engines, etc., can solve adjustment problems, achieve the effects of expanding the adjustment range, avoiding jamming, and strengthening sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

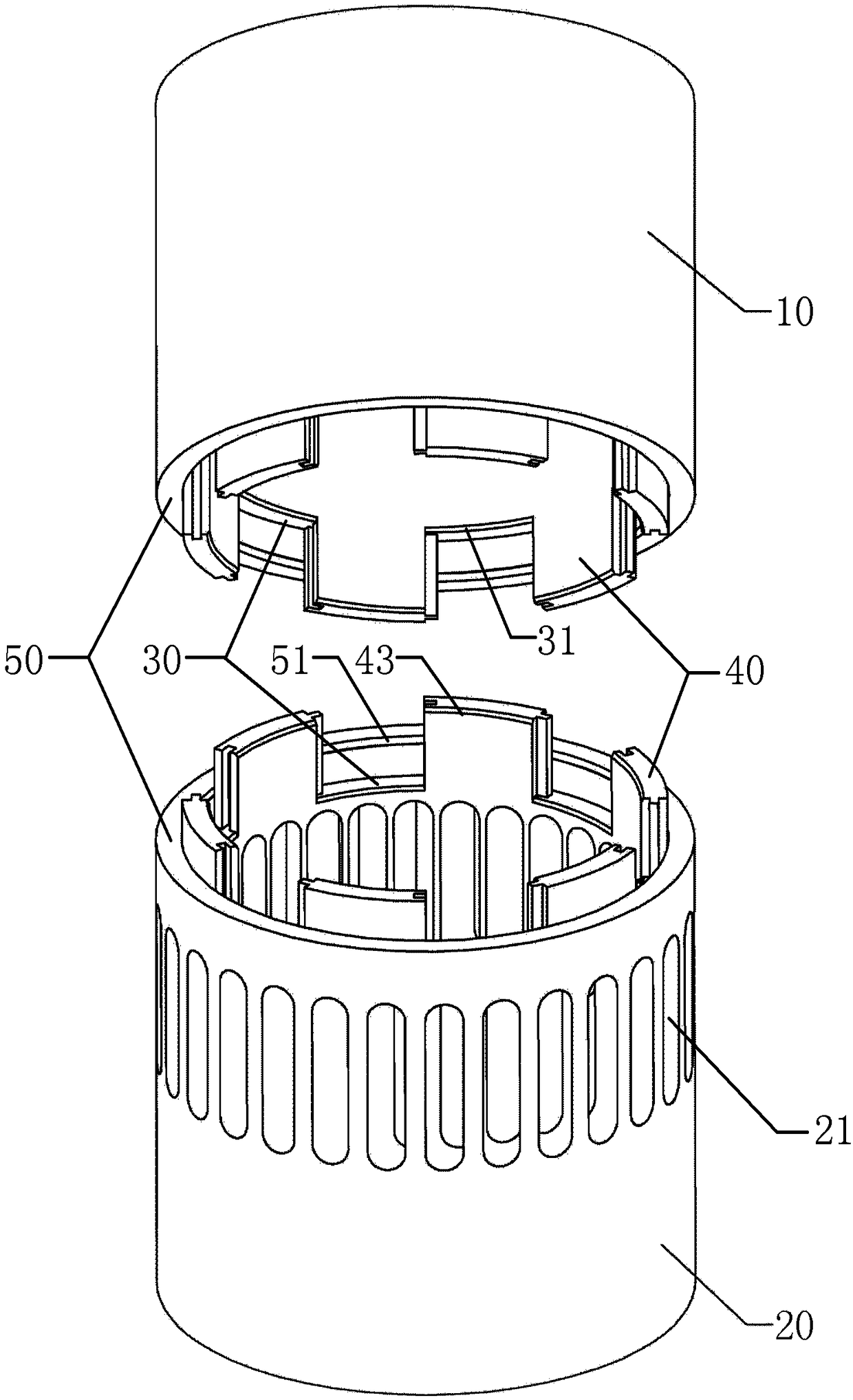

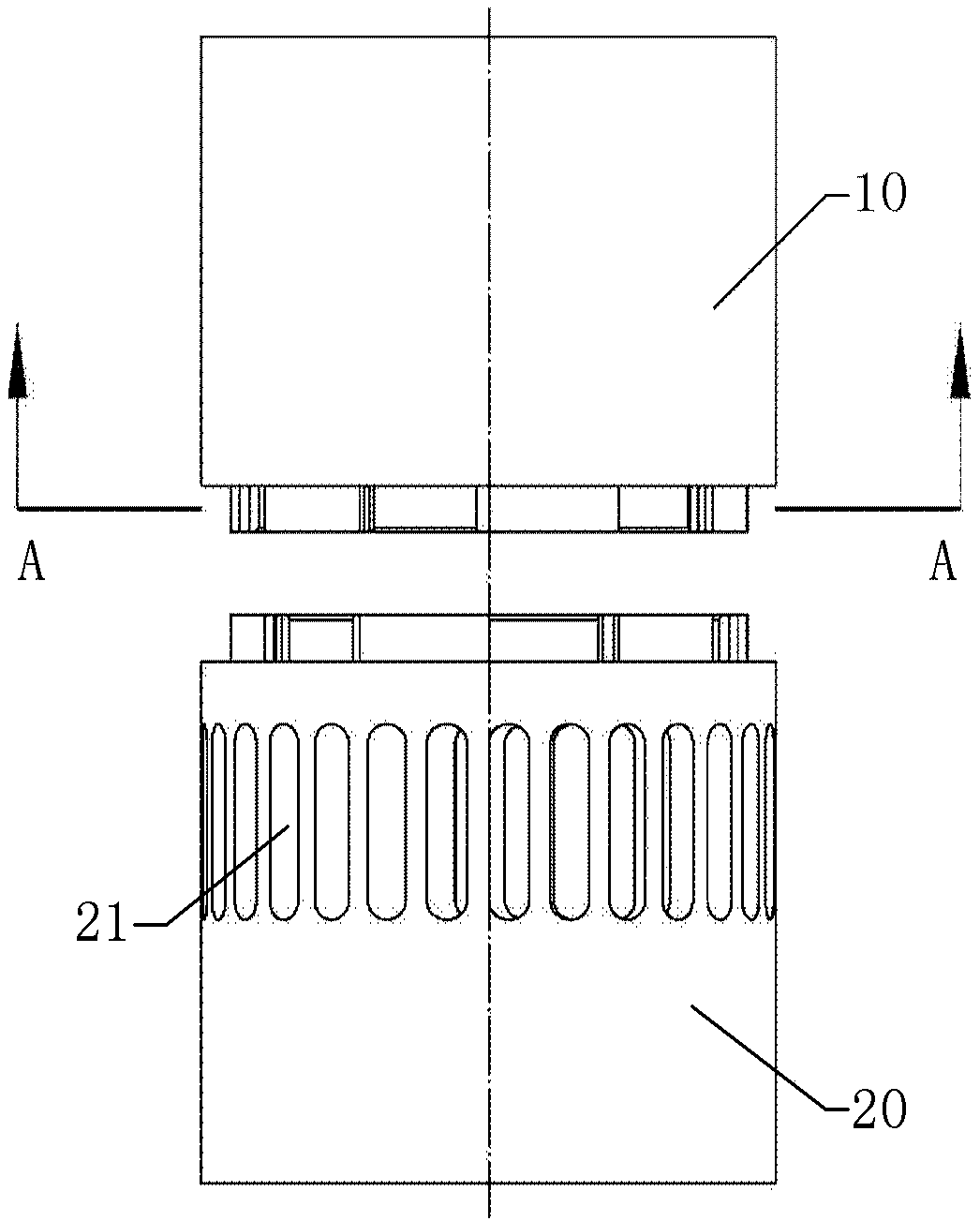

[0053]The DC scavenging engine cylinder liner, assembly and engine with variable scavenging phase provided by the embodiments of the present disclosure divide the traditional DC scavenging two-stroke engine cylinder liner into upper and lower parts near the upper end of the scavenging port. The teeth-shaped structures mesh with each other, so that the scavenging port can move up and down as a whole to change the scavenging phase, and then make appropriate adjustments according to the actual working conditions, so that the engine can meet the requirements of power, economy and emission.

[0054] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0055] figure 1 A schematic diagram of an exploded structure of a cylinder liner of a direct-flow scavenging engine with variable sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com