Embedded spring type dual locknut

A anti-loosening nut, double technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of low work efficiency, low yield, high production cost, etc., achieve simple structure, prevent loosening, and achieve convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

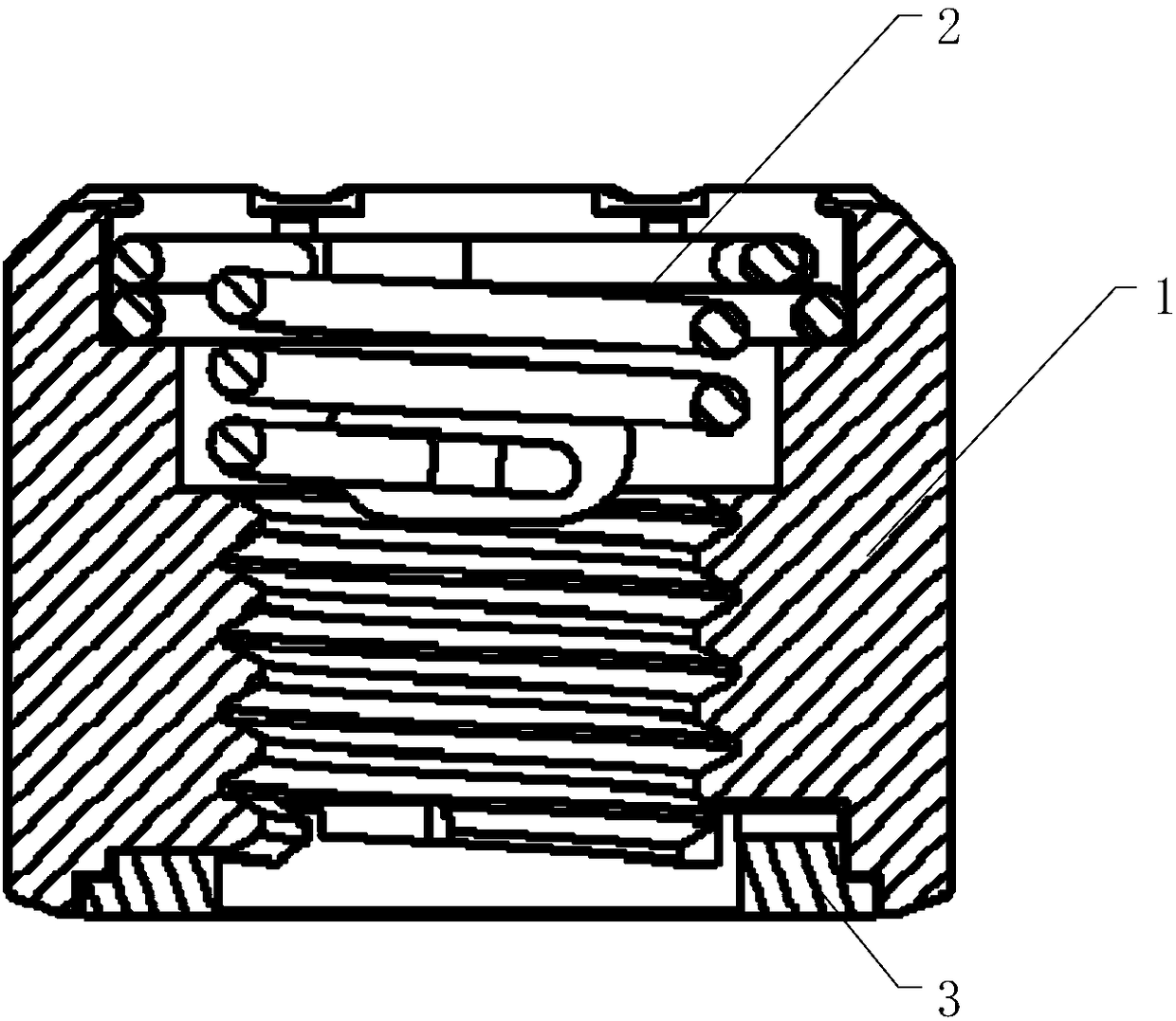

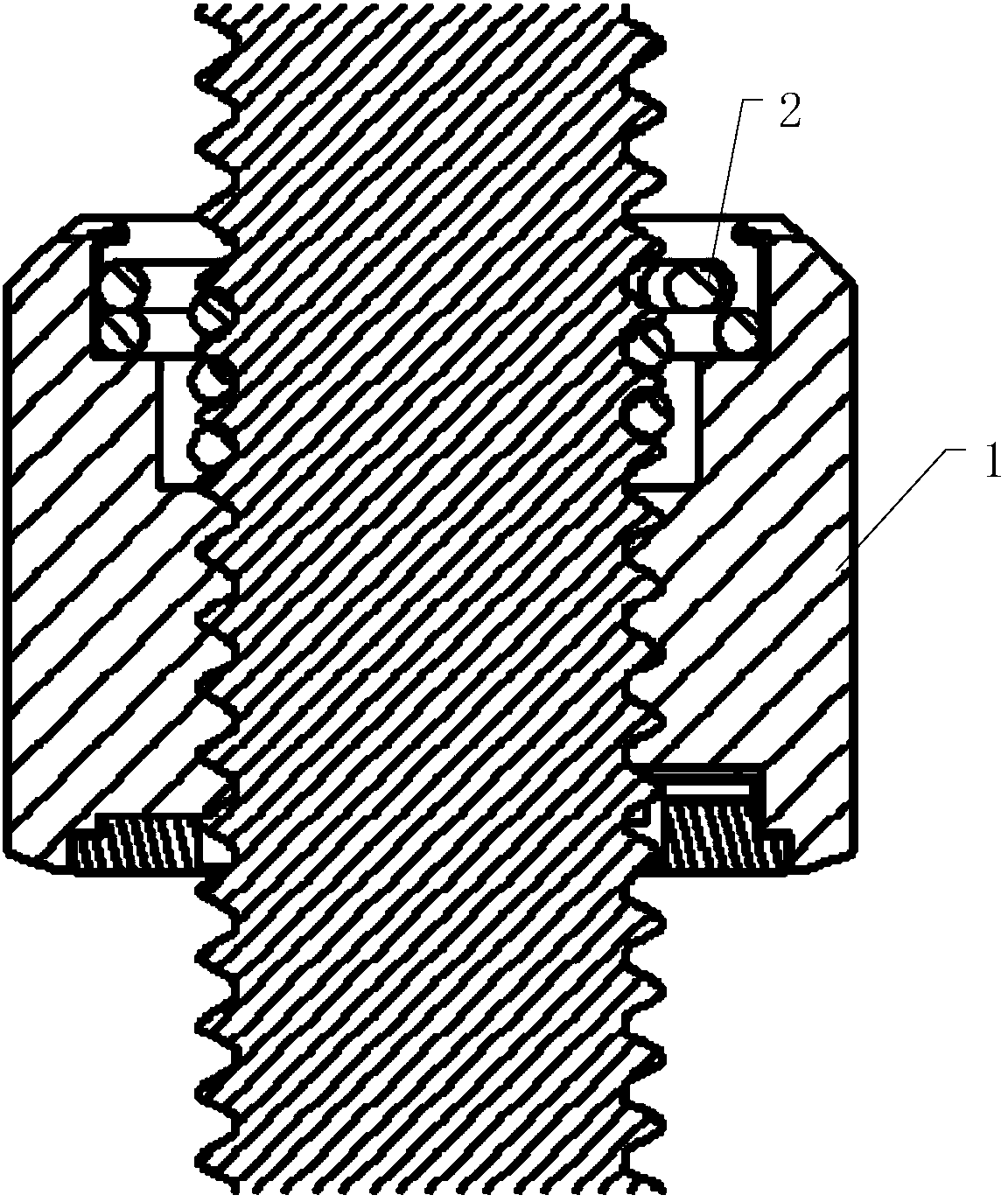

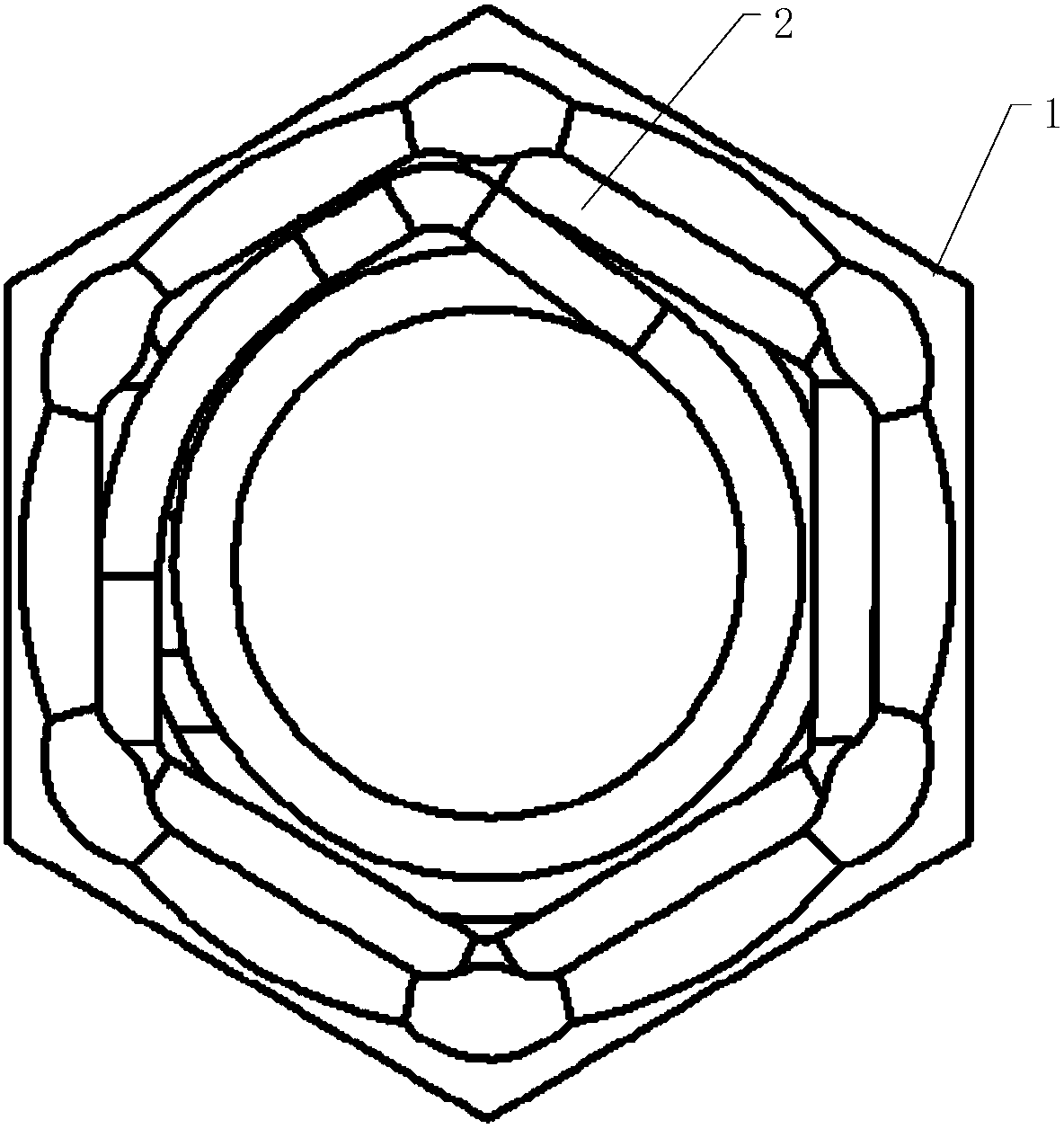

[0038] Such as Figure 1 ~ Figure 3 ,as well as Figure 7 , Figure 8As shown, this embodiment discloses an embedded spring type double locknut, including a nut body 1, a coil spring element 2 arranged at the upper end of the nut body, and a washer 3 arranged at the lower end of the nut body. Specifically, the lower end surface of the nut body is provided with a gasket groove 102 connected to the central threaded hole 101 of the nut body. Divided into a plurality of bosses 102a, the top end surface of the boss is an inclined plane or an inclined curved surface, and the inclination angle of the top end surface is greater than the helix angle of the central threaded hole; the gasket is circular and is located in the gasket groove, the gasket The inner diameter of the sheet is greater than or equal to the major diameter of the central threaded hole; one end surface of the gasket is provided with a bump 301 that contacts and fits with the boss, and the contact surface between th...

Embodiment 2

[0056] This embodiment discloses a spring-embedded double anti-loosening nut, which includes a nut body, a helical spring member arranged at the upper end of the nut body, and a washer arranged at the lower end of the nut body. Specifically, the lower end surface of the nut body is provided with a gasket groove connected to the central threaded hole of the nut body, and the groove bottom of the gasket groove is evenly distributed with draw-in grooves on the circumference, and the grooves divide the groove bottom of the gasket groove into A plurality of bosses, the top end surface of the boss is an inclined plane or an inclined curved surface, and the inclination angle of the top end surface is greater than the helix angle of the central threaded hole; the gasket is circular and located in the gasket groove, and the inner diameter of the gasket Greater than or equal to the major diameter of the central threaded hole; one side of the gasket is provided with a bump that contacts a...

Embodiment 3

[0061] This embodiment discloses a spring-embedded double anti-loosening nut, which includes a nut body, a helical spring member arranged at the upper end of the nut body, and a washer arranged at the lower end of the nut body. Specifically, the lower end surface of the nut body is provided with a gasket groove connected to the central threaded hole of the nut body, and the groove bottom of the gasket groove is evenly distributed with draw-in grooves on the circumference, and the grooves divide the groove bottom of the gasket groove into A plurality of bosses, the top end surface of the boss is an inclined plane or an inclined curved surface, and the inclination angle of the top end surface is greater than the helix angle of the central threaded hole; the gasket is circular and located in the gasket groove, and the inner diameter of the gasket Greater than or equal to the major diameter of the central threaded hole; one side of the gasket is provided with a bump that contacts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com