A preparation method of photothermal bioanode, photothermal bioanode and application thereof

A biological anode and photothermal technology, applied in the field of electrochemical catalysis, can solve the problems of increased wastewater treatment cost, poor wastewater treatment effect, poor practicability, etc., and achieve the effects of cost economy, excellent power generation performance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this example, a photothermal bioanode is prepared, and its specific preparation process includes the following steps:

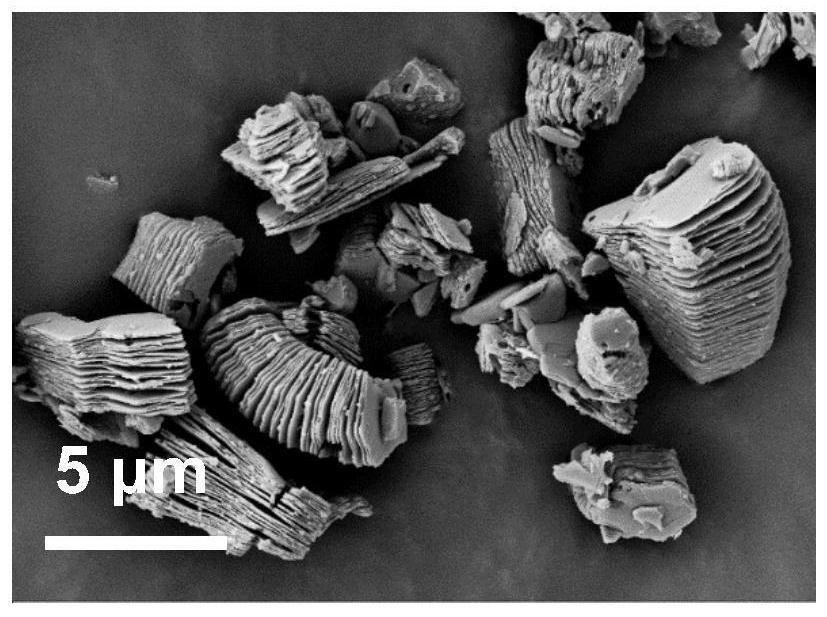

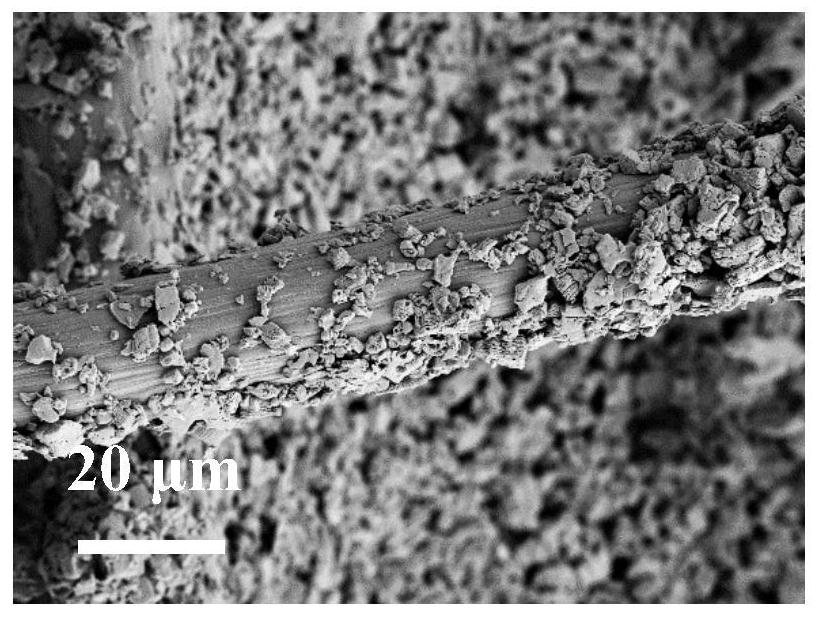

[0035] 1. Take 200 mesh sieve, 0.5g of Ti 3 AlC 2 Put in a 50mL polytetrafluoroethylene beaker, add 10mL of HF solution with a mass percentage concentration of 48%, and place the beaker on a magnetic stirrer for stirring and mixing; then, heat to 60°C, react at a constant temperature for 24h, and centrifuge to obtain Ti 3 C 2 T x As the MXene material; then, the MXene material is washed alternately and repeatedly with deionized water and absolute ethanol until the washing liquid is neutral, then placed in a vacuum drying oven at 80°C for 24 hours, taken out, and ground through a 200-mesh sieve to obtain MXene nanolayered materials.

[0036] 2. Disperse 0.25 mg of MXene nano-layered material in 0.5 mL of absolute ethanol, add 0.1 mL of binder, stir and mix to obtain a slurry; wherein, the binder is selected as a perfluorosulfonic acid polymer s...

Embodiment 2

[0039] Embodiment 2 Light-to-heat conversion performance test

[0040] 1. Grouping

[0041] Take ordinary carbon felt as the reference substance;

[0042] The photothermal bioanode prepared in Example 1 was taken as a sample.

[0043] 2. Sun exposure

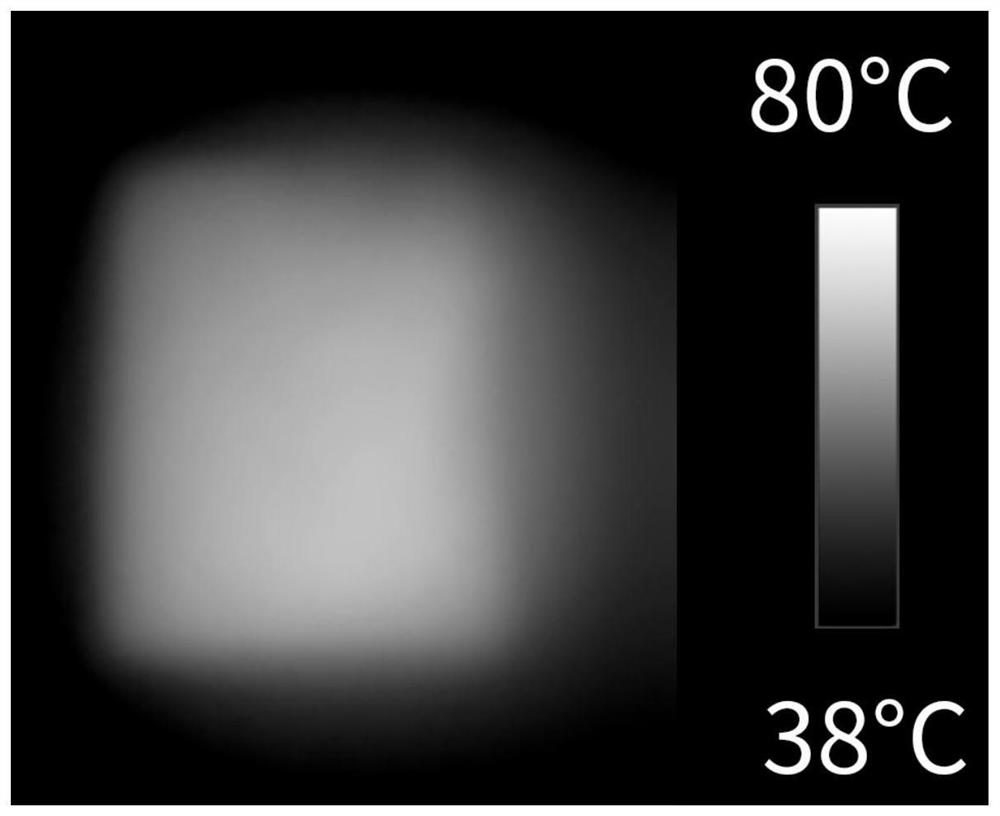

[0044] Expose the reference substance and sample to sunlight for irradiation, and use an optical power density meter (TES-1333) to measure the solar power density as 1000W / m 2 , using an infrared thermal imaging camera (FTIRETS320) to observe and measure the surface heating process of the reference substance and the sample. image 3 and Figure 4 shown.

[0045] By comparison, it can be found that the MXene nano-layered material prepared by the present invention has better light absorption ability and photothermal conversion effect, and it has a wider absorption spectrum, and the range of light bands absorbed can be from ultraviolet to infrared bands, especially for infrared It has better absorption with near-infrared, and...

Embodiment 3

[0046] Application effect of embodiment 3 in three-electrode bioelectrochemical system

[0047] 1. Construct a three-electrode electrochemical system device according to the traditional method, and control the ambient temperature in the reaction vessel through an external circulating water system, use ordinary carbon felt and the photothermal bioanode prepared in Example 1 as anodes, and divide them into control group 1 and experimental group 1.

[0048] The anodes of control group 1 and experimental group 1 were cut into a square shape of 4cm×4cm, with a thickness of 0.5cm. Titanium wire was used as an auxiliary electrode, and a saturated calomel electrode was used as a reference electrode to construct a three-electrode system microbial electrochemical system.

[0049] 2. Use anaerobic mixed strain solution and sodium acetate culture solution, place it in a constant temperature incubator at 30°C for cultivation, and connect it to an electrochemical workstation (Shanghai Chenh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com