A motor shock absorber

A shock absorbing device and support device technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of poor vibration damping effect, affecting the rotor, reducing driving comfort, etc., to solve fatigue failure, improve reliability, The effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

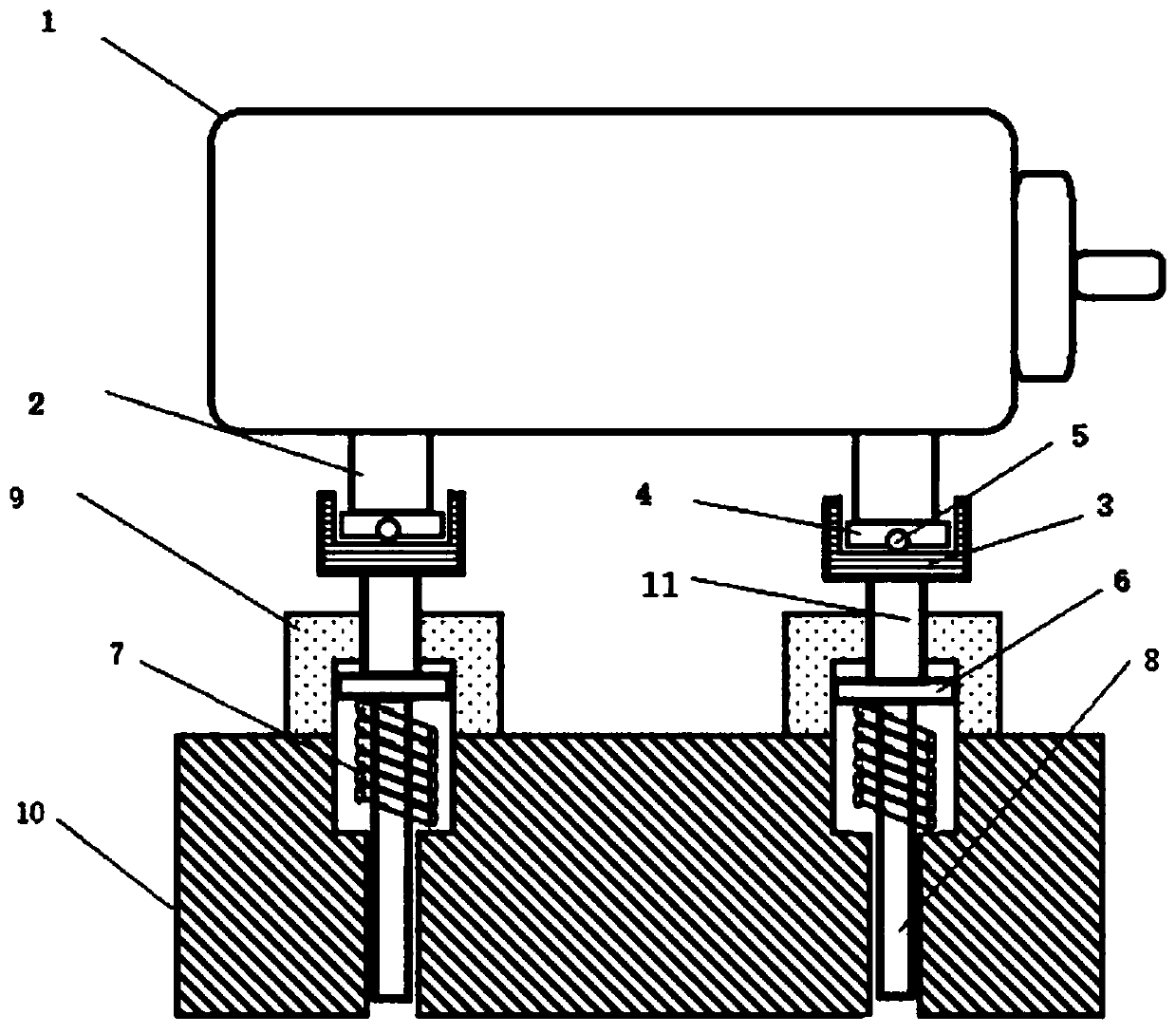

[0014] Such as figure 1 As shown, a motor shock absorber, which includes: a support device 2, a shock absorbing amplitude adjustment device and a fixed base, the support device is arranged on the lower side of the motor housing 1 for supporting the motor; the shock absorber The vibration amplitude adjustment device is connected with the support device, and is used to adjust the reverse amplitude according to the vibration amplitude of the motor; the shock-absorbing amplitude adjustment device includes a shock-absorbing device and an elastic adjustment device; wherein the shock-absorbing device includes a main elastic block 3 And auxiliary elastic block 4, described auxiliary elastic block is arranged on the lower end of supporting device, is provided with amplitude adjustment bead 5 between described main elastic block and auxiliary elastic block; Described elastic adjustment device comprises guide bar 11, pressing block 6 , spring 7 and moving rod 8, wherein the guide rod is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com