Sand screening machine for indoor decoration

A technology of sand screening machine and interior decoration, applied in the direction of screen, solid separation, grille, etc., can solve the problems of inoperability, heavy workload, inability to use, etc., and achieve the effect of reducing energy consumption, easy handling, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

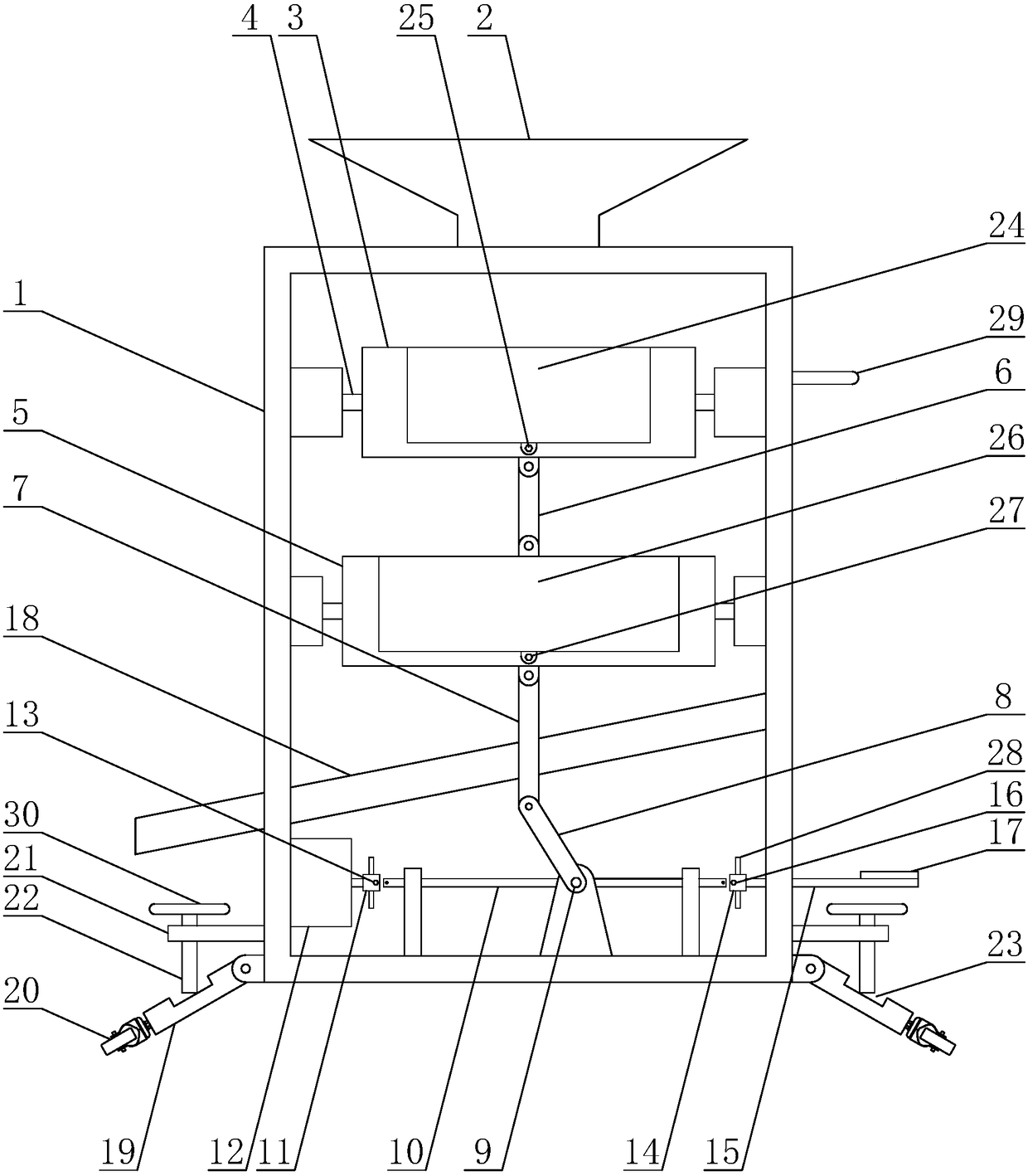

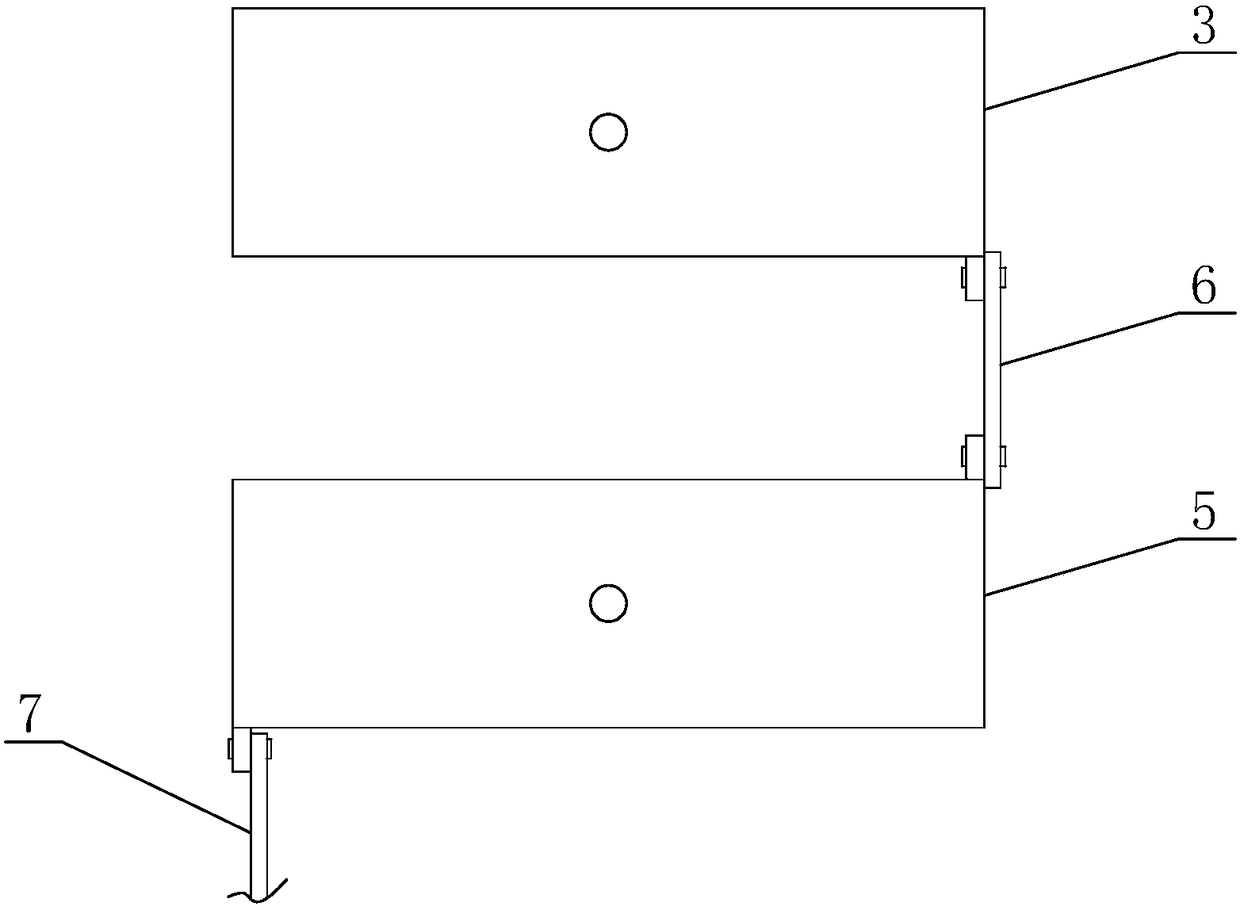

[0028] Example: such as figure 1 As shown, the present invention is a sand screening machine for indoor decoration, including a frame 1, the bottom array of the frame 1 is provided with four support arms 19, and one end of the support arm 19 is connected to the frame through a hinge shaft. 1 hinged, the other end is equipped with a universal wheel 20, the upper side of the support arm 19 is provided with a support block 21, the support block 21 is welded on the frame 1, and the support block 21 is vertically provided with support screws 22. A threaded hole compatible with the support screw 22. The support arm 19 is provided with a slot 23 compatible with the support screw 22. Tighten the support screw 22 downward, and the bottom of the support screw 22 is inserted into the slot 23 , can make the universal wheels 20 contact with the ground, and then lift the frame 1, which can facilitate the transportation of the present invention. Preferably, a hand wheel 30 is welded on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com