Preparation method for improving friction and wear properties of 6xxx series aluminum alloy

A friction and wear, aluminum alloy technology, which is applied in the field of preparation of improving the friction and wear properties of 6xxx series aluminum alloys, can solve the problems of low friction and wear properties, low manufacturing costs, etc., and achieves improved friction and wear properties, reduced energy consumption, and high plastic toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

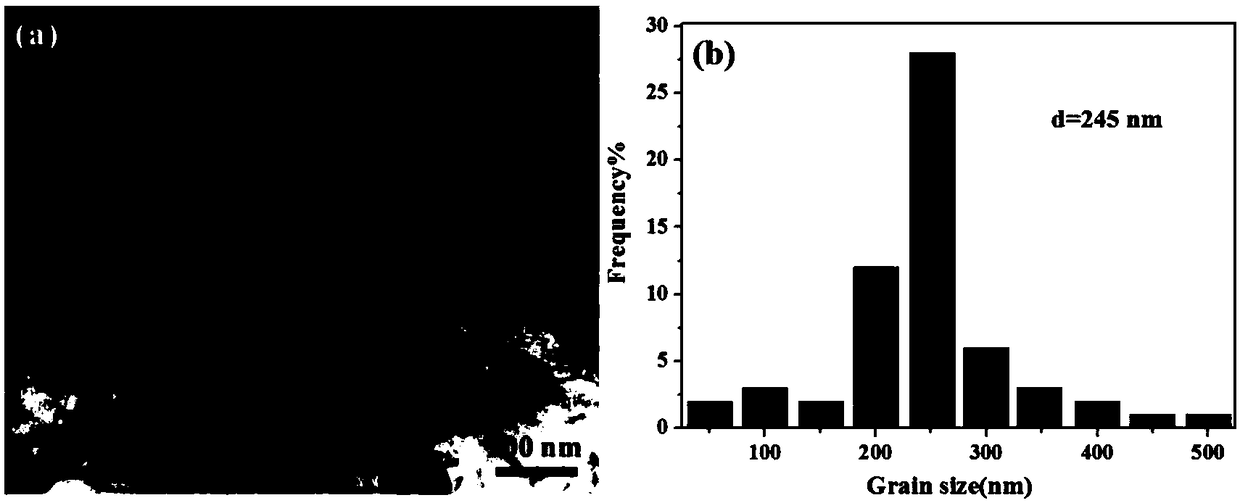

[0071] Example 1 (dynamic aging at 170°C)

[0072] The 6xxx series Al-Mg-Si-Cu aluminum alloy is cast into a round billet with a diameter of 100mm, processed into a profile with a size of 80×80×300mm by turning, and the profile is processed in a circulating air resistance furnace for 520 Homogenization treatment at ℃×24h, the homogenized profile is subjected to solution treatment and water quenching at 530°C×2h in a circulating air resistance furnace, and then the profile after solution quenching is immediately subjected to equal-channel angular extrusion dynamics Aging, the temperature of dynamic aging for equal channel angular extrusion is 170°C, the process of equal channel angular extrusion is: the inner intersection angle of two channels Φ = 90°, the outer arc angle Ψ = 0°, extrusion 4 passes, extrusion The speed is 5mm s -1 , followed by the average grain size determination, tensile test and friction and wear test of the 170 °C equal channel angular extrusion dynamicall...

Embodiment 2

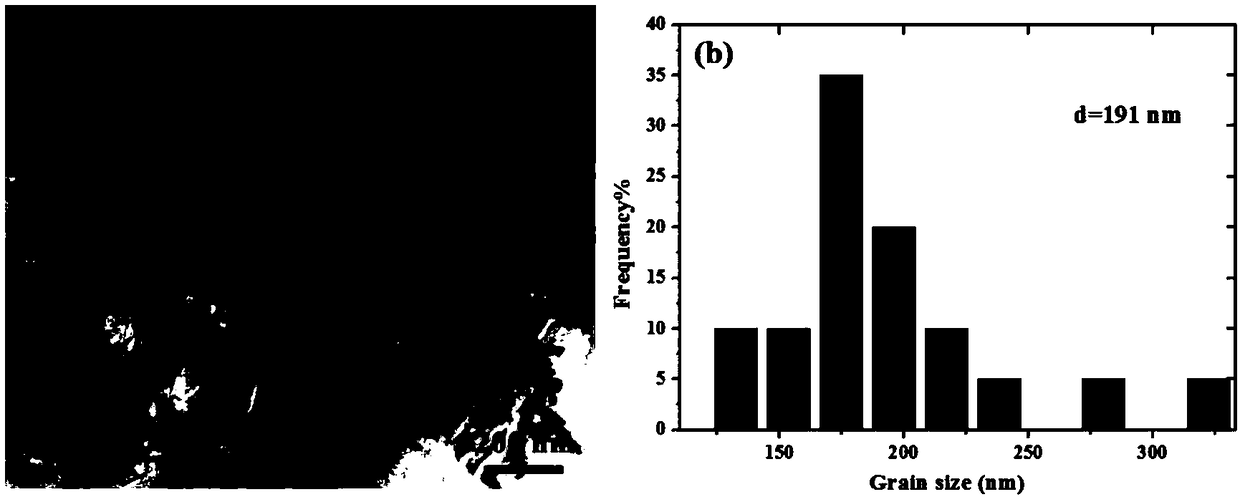

[0075] Example 2 (dynamic aging at 110°C)

[0076] The 6xxx series Al-Mg-Si-Cu aluminum alloy is cast into a round billet with a diameter of 100mm, processed into a profile with a size of 80×80×300mm by turning, and the profile is processed in a circulating air resistance furnace for 520 Homogenization treatment at ℃×24h, the homogenized profile is subjected to solution treatment and water quenching at 530°C×2h in a circulating air resistance furnace, and then the profile after solution quenching is immediately subjected to equal-channel angular extrusion dynamics Aging, the temperature of dynamic aging for equal channel angular extrusion is 110°C, the process of equal channel angular extrusion is: the inner intersection angle of two channels Φ = 90°, the outer arc angle Ψ = 0°, 4 passes of extrusion, extrusion The speed is 5mm s -1 , followed by 110 ° C equal channel angular extrusion dynamic aging of the aluminum alloy for the determination of the average grain size, tensil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature tensile strength | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Room temperature tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap