Automatic open-close flap gate provided with longitudinal oblique shaft

A technology of automatic opening and closing, flap gate, applied in water conservancy engineering, marine engineering, coastline protection and other directions, can solve the problems of flapping vibration, affecting the water passing capacity, large water passing area, etc., and achieve the effect of smooth drainage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

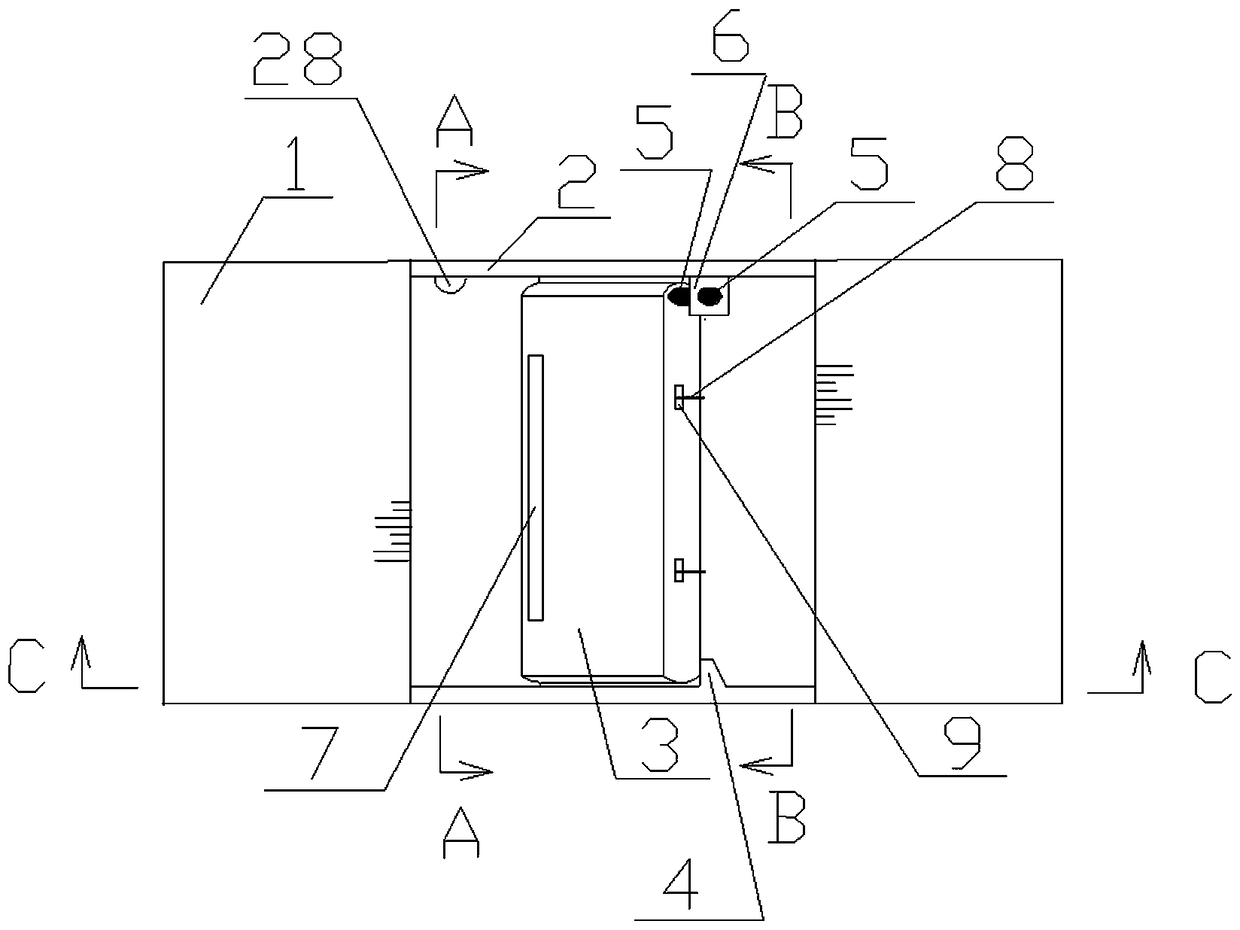

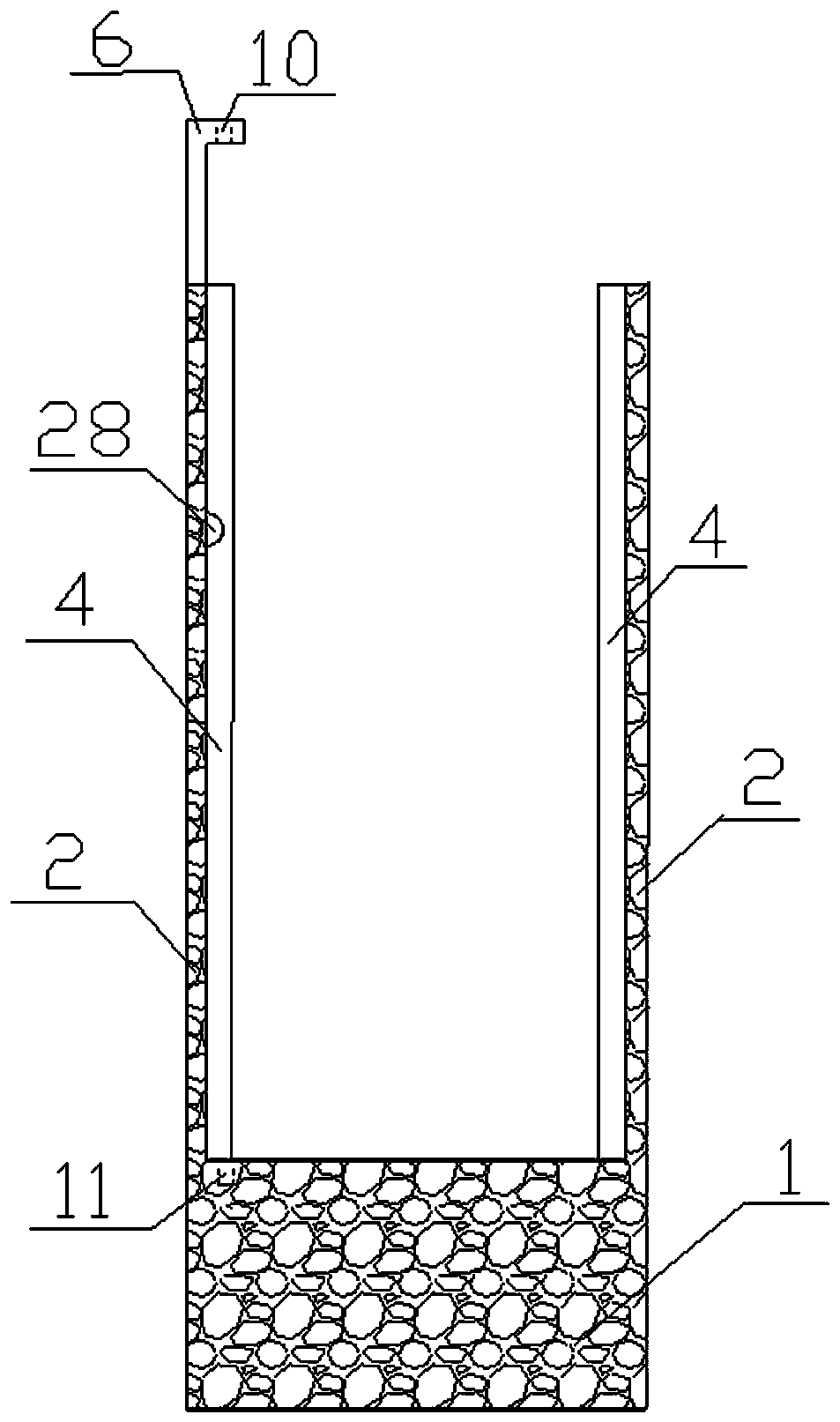

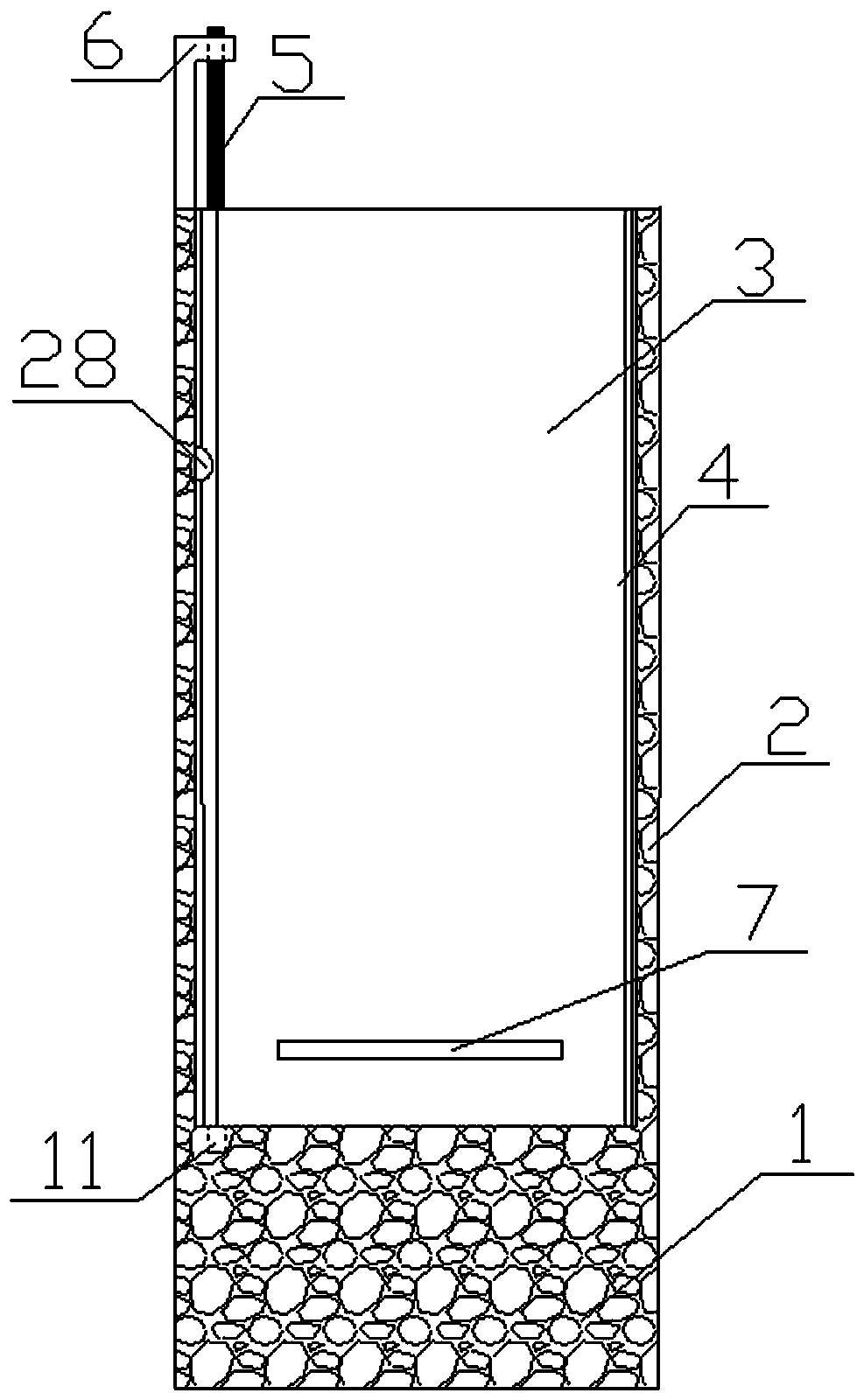

[0026] Such as Figure 1-16 As shown, the oblique axis longitudinal automatic opening and closing flap gate of the present invention consists of a barrage 1, a gate pier 2, a gate 3, a backwater panel 301, a water facing panel 302, a bar 4, an oblique axis 5, and an oblique axis support plate 6 , water discharge hole 7, bracket 8, bracket hole 9, upper inclined axis hole 10, lower inclined axis hole 11, pontoon 12, pontoon guide rail 13, water inlet 14, pontoon runner 15, upper hook plate 16, Lower hook plate 17, sliding door 18, vertical plate 19, horizontal baffle plate 20, control panel 21, control panel slot 22, sliding door runner 23, adjusting screw 24, gate cavity 25, connection support 26, sliding door guide rail 27 , a limit block 28, and a one-way valve 29, the gate pier 2 is fixedly arranged on the barrage 1, the bar 4, the inclined axis support plate 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com